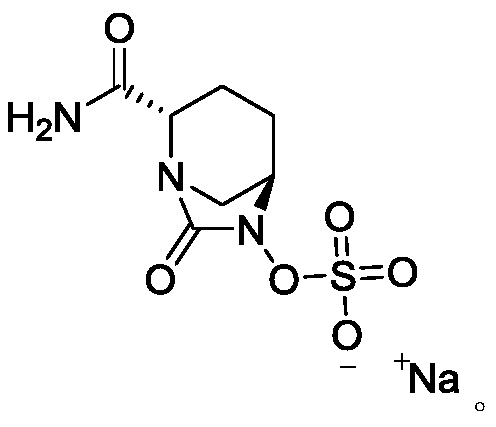

A method for preparing amorphous avibactam sodium by spray drying

A kind of avibactam sodium, amorphous technology, applied in the field of preparation of amorphous avibactam sodium, can solve the problems of environmental hazards, long freeze-drying cycle, high energy consumption, etc., achieve low production cost, simple steps, Ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A dichloromethane (100ml) solution of sodium isooctanoate (3.8g, 22mmol) was added dropwise to avibactam tetrabutylammonium salt (10g, 19.7mmol) in a dichloromethane solution (100ml), keeping the reaction temperature at At 20°C, the dropwise addition was completed in 20 minutes. After dripping and keeping warm for 3 hours, add 200ml of purified water for extraction, and the water phase enters the spray dryer (control the air inlet temperature at 150°C, the air outlet temperature at 80°C, and the injection volume at 75ml / min) to obtain 5.2g of solid matter. Yield 92%. The solid substance: amorphous, disorderly arrangement.

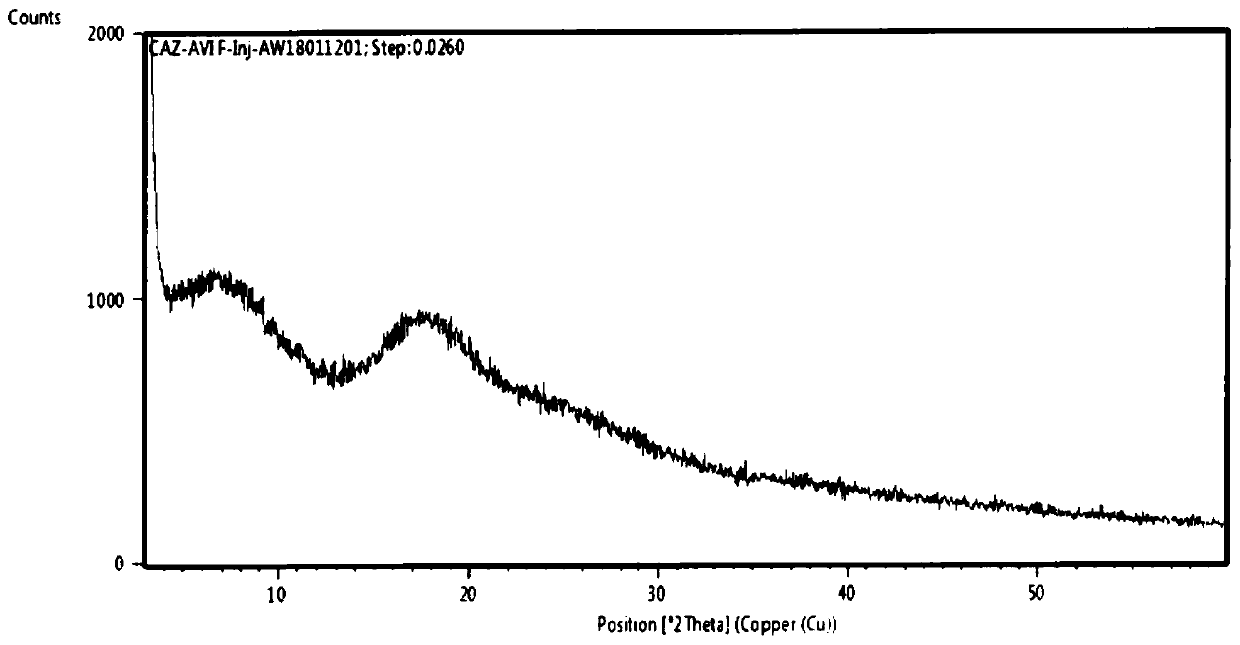

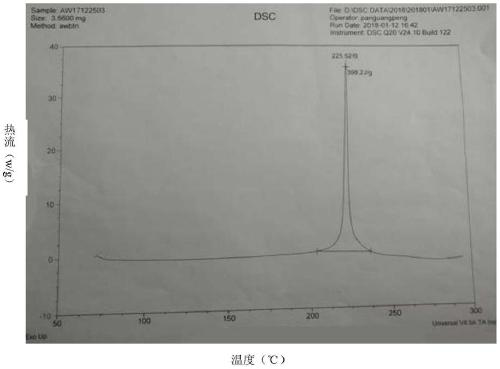

[0036] The above-mentioned solid is detected by two methods of XRD spectrum and DSC spectrum, as follows:

[0037] 1. The detection method of XRD pattern is as follows:

[0038] Instrument: PANalytical powder X-ray diffractometer;

[0039] Model: XpertPROMPD;

[0040] Test method: the target material is copper, the light pipe is set (40kv, 40mA)...

Embodiment 2

[0052] The n-butanol (200ml) solution of sodium isooctanoate (7.6g, 44mmol) was added dropwise in the n-butanol solution (200ml) of avibactam tetrabutylammonium salt (20g, 39.4mmol), keeping the reaction temperature at 20°C, 20min dropwise addition, heat preservation reaction for 3h, add 400ml of purified water for extraction, the water phase enters the spray dryer (air inlet temperature is 150°C, air outlet temperature is 80°C, injection volume is 75ml / min) to obtain a solid drying The dry weight is 10.51g, and the yield is 93%. The solid substance: amorphous, disorderly arrangement.

Embodiment 3

[0054] A solution of ethyl acetate (200ml) of sodium isooctanoate (7.6g, 44mmol) was added dropwise to a solution of ethyl acetate (200ml) of avibactam tetrabutylammonium salt (20g, 39.4mmol), keeping the reaction temperature at 20°C, 20min dropwise addition, heat preservation reaction for 3h, add 400ml of purified water for extraction, the water phase enters the spray dryer (air inlet temperature is 150°C, air outlet temperature is 80°C, injection volume is 75ml / min) to obtain a solid drying The dry weight is 10.29g, and the yield is 91%. The solid substance: amorphous, disorderly arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com