Method for regenerating acidic waste etching solution through synergistic oxidation by using hydrogen peroxide generated through oxygen cathode reduction and chlorine generated through anodic oxidation

An acid etching waste liquid, anodizing technology, applied in the field of PCB acid etching liquid etching process, can solve the problems of poor chemical stability of hydrogen peroxide, weak oxidation ability, slow regeneration rate, etc. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

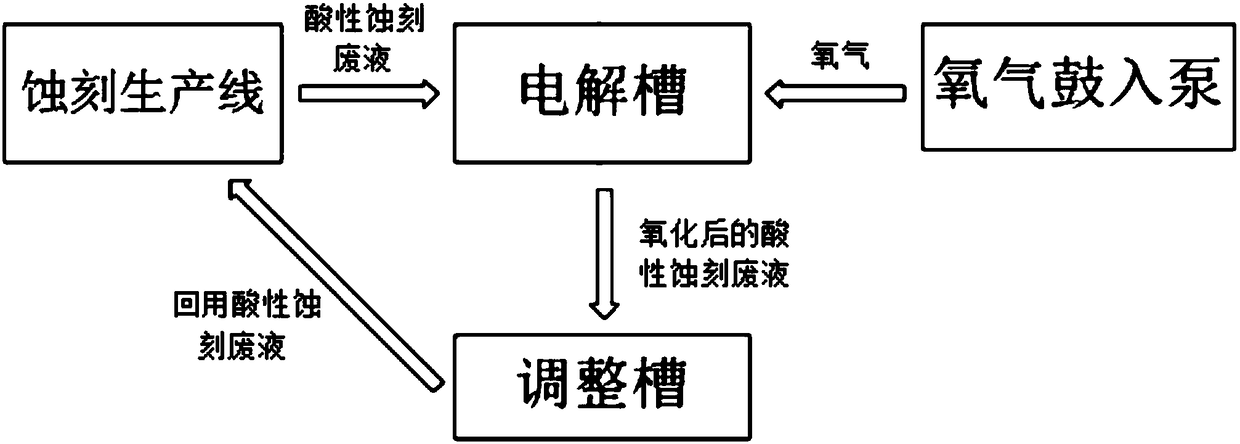

[0032] The method of synergistically oxidizing and regenerating acid etching waste liquid by using hydrogen peroxide generated by oxygen cathode reduction and chlorine generated by anodic oxidation includes the following steps:

[0033] (1) Prepare an acidic etching solution with a total copper concentration of 130g / L (no monovalent copper ions), an acidity value of 1.5N, and a chloride ion concentration of 260g / L for the etching machine;

[0034] (2) The acid etching waste liquid flows out from the etching production line. Due to the reaction during the etching process, the monovalent copper ion concentration in the acid etching waste liquid rises to 1.4g / L and the ORP value drops to 425mv at this time;

[0035] (3) The acid etching waste liquid from the printed circuit board production line is introduced into the electrolytic tank through the etching tank, and the flow rate of the acid etching waste liquid into the electrolytic tank is 3.6m 3 / h, then 1.0m 3 / h gas flow oxygen into ...

Embodiment 2

[0039] The method of synergistically oxidizing and regenerating acid etching waste liquid by using hydrogen peroxide generated by oxygen cathode reduction and chlorine generated by anodic oxidation includes the following steps:

[0040] (1) Prepare an acidic etching solution with a total copper concentration of 150g / L (no monovalent copper ions), an acidity value of 1.6N, and a chloride ion concentration of 260g / L for the work of the etching machine;

[0041] (2) The acid etching waste liquid flows out from the etching production line. Due to the reaction in the etching process, the monovalent copper ion concentration in the acid etching waste liquid rises to 1.2g / L, and the ORP value drops to 430mv;

[0042] (3) The acid etching waste liquid flowing out of the printed circuit board production line is introduced into the electrolytic tank through the etching tank, and the acid etching liquid is 4.0m 3 / h flow from the etching cylinder into the electrolytic cell, and then at 1.6m 3 / h ...

Embodiment 3

[0046] The method of synergistically oxidizing and regenerating acid etching waste liquid by using hydrogen peroxide generated by oxygen cathode reduction and chlorine generated by anodic oxidation includes the following steps:

[0047] (1) Prepare an acidic etching solution with a total copper concentration of 170g / L (no monovalent copper ions), an acidity value of 2.0N, and a chloride ion concentration of 260g / L for use in the etching machine;

[0048] (2) The acid etching waste liquid flows out from the etching production line. Due to the reaction during the etching process, the monovalent copper ion concentration in the acid etching waste liquid rises to 1.6g / L and the ORP value drops to 420mv at this time;

[0049] (3) The acid etching waste liquid flowing out of the printed circuit board production line is introduced into the electrolytic tank through the etching tank, and the acid etching solution is 5.4m 3 / h flow from the etching tank to the electrolytic tank, and then at 1.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com