Method for reducing oxygen with acetylene black hydrophobic cathode for preparing hydrogen peroxide

A technology for the preparation of hydrogen peroxide and oxygen, which is applied in the direction of electrodes, electrolysis process, electrode shape/type, etc., and can solve the problems of high energy consumption and low catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

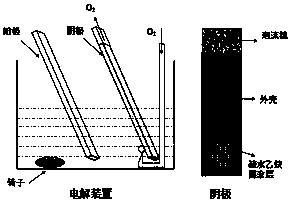

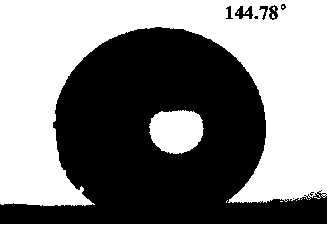

[0020] At room temperature, disperse 1 g of PTFE dispersion in 2.5 mL of 50% ethanol aqueous solution, add 0.1 g of acetylene black, and mix to form a paste. Then take about 1 g of electrode paste and put it on the nickel foam cleaned by ethanol and scrape it flat, then take about 1 g of electrode paste and gently roll it with a glass rod. After air-drying, it was dried in a blast oven at 250°C for 40 min. It is then sealed with waterproof tape, leaving only the coated part exposed. The coating thickness of the prepared electrode is 0.48 mm, and the width of the surface crack is about 0.2 mm. When doing the hydrophobicity test, the contact angle with water droplets is 144.78°.

Embodiment 2

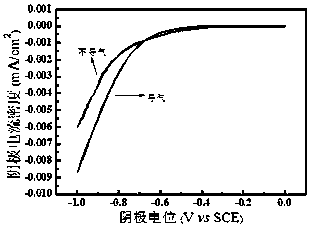

[0022] The cathode prepared in Example 1 was installed in the electrolytic cell, and the linear polarization test was carried out under the conditions of no gas conduction and gas conduction respectively. The scan rate is 50 mV / s, and the potential range is 0~-1 V ( vs SCE), the electrolyte is 0.1 mol / L Na 2 SO 4 solution. It is found that the polarization curve is as stable when the gas is conducted as when it is not conducted, indicating that the three-phase interface on the cathode surface is very stable and is not affected by the air flow.

Embodiment 3

[0024] At room temperature, disperse 1 g of polytetrafluoroethylene dispersion in 5 mL of 50% ethanol aqueous solution, add 0.2 g of acetylene black, and mix to form a paste. Then take about 1 g of electrode paste and put it on the nickel foam cleaned by ethanol and scrape it flat, then take about 1 g of electrode paste and gently roll it with a glass rod. After air-drying, it was dried in a blast oven at 340°C for 40 min. The thickness of the obtained coating is 0.54 mm, the width of the surface crack is about 0.12 mm, and the contact angle with water droplet is 135.34°. With the prepared cathode at an oxygen flow rate of 40mL / min, 100 mA / cm 2 Constant current electrolysis was performed for 1 h at the cathodic current density. The cathode-to-anode area ratio is 0.5, and the electrolyte is 0.1 mol / L Na 2 SO 4 solution. Hydrogen peroxide 10.1 mmol / L was produced after electrolysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com