Measurement platform for measuring time response characteristics of ultra-high speed camera

An ultra-high-speed camera and time-response technology, applied in the field of detection, can solve problems such as difficulty in maintaining consistent optical fiber output light intensity, insufficient measurement accuracy, and complex fiber bundle arrays, achieving comprehensive and accurate measurement results and simple measurement operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing description and embodiment, and the mode of the present invention includes but not limited to following embodiment.

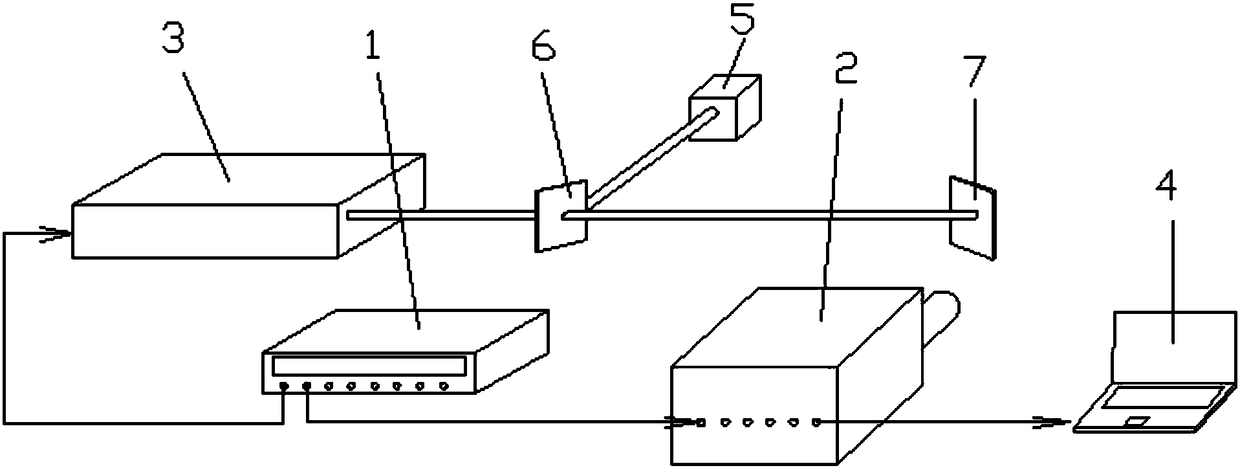

[0036] This embodiment provides an ultra-high-speed camera time response measurement platform, such as figure 1 As shown, the measurement platform includes Stanford Research Systems DG645 or higher-precision synchronous machine 1, ultra-high-speed camera 2, ultrashort pulse laser 3, PC 4, energy card meter 5, beam splitter 6 and diffuse reflection screen 7 .

[0037] Wherein, the high-precision synchronous machine 1 is provided with two output terminals, one output terminal is opposite to the ultrashort pulse laser, and is used to trigger the ultrashort pulse laser 3 so that the ultrashort pulse laser 3 outputs a single pulse laser beam, and the other The output end is opposite to the ultra-high-speed camera 2 to trigger the ultra-high-speed camera 2; the beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap