All-fiber high-order mode Brillouin fiber laser

A fiber laser, high-order mode technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of beam power and quality degradation, low purity of output high-order mode modes, etc., to achieve easy promotion and use, improve practicability and reliability. performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

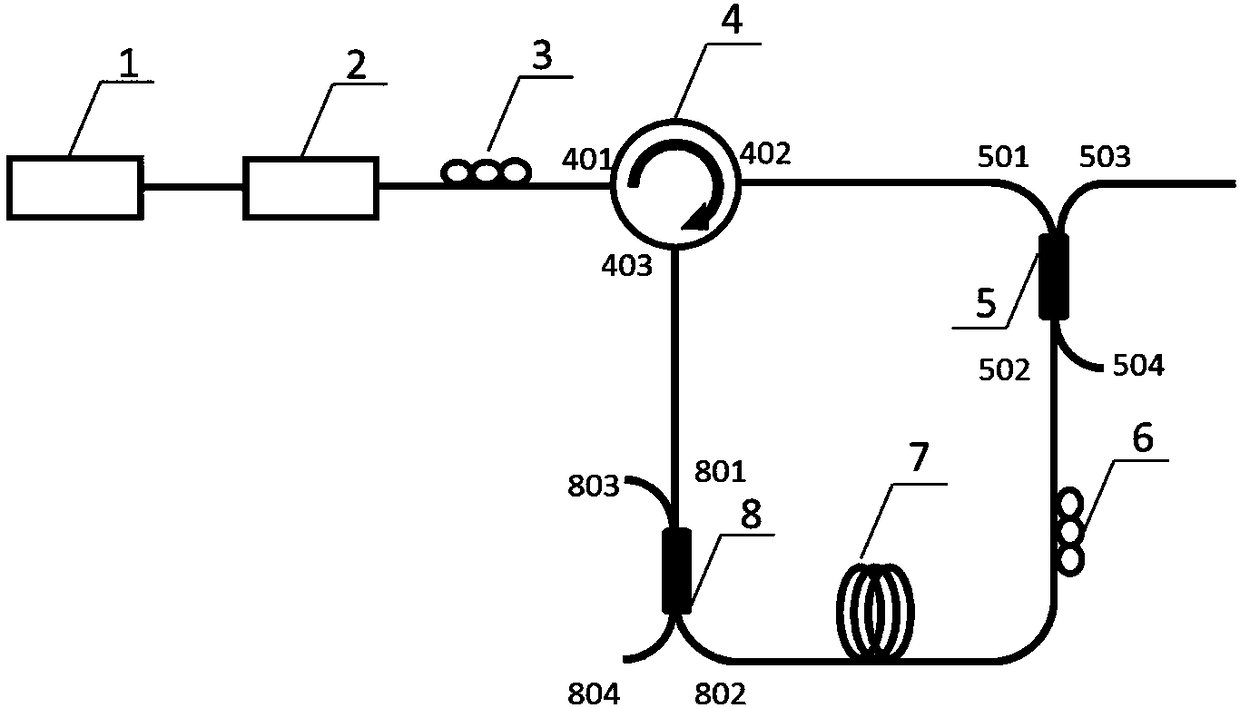

[0025] like figure 1 As shown, an all-fiber high-order mode Brillouin fiber laser of this example includes: a narrow linewidth pump laser 1, an optical amplifier 2, a first polarization controller 3, a fiber circulator 4, and a first fiber mode selective coupler 5. The second polarization controller 6 , the few-mode fiber 7 and the second fiber mode selective coupler 8 .

[0026] The laser output by the narrow linewidth pump laser 1 is power amplified by the amplifier 2, and the amplified high-power pump light is injected into the first port 401 of the fiber circulator 4, and then injected into the first port 402 from the second port 402 of the fiber circulator 4. The first port 501 of the fiber mode selective coupler 5, after passing through the first fiber mode selective coupler 5, the pump light is converted from the fundamental transverse mode of the single-mode fiber in the first port 501 to the first fiber mode selective coupler 5. The pump light of the specific high-or...

Embodiment 2

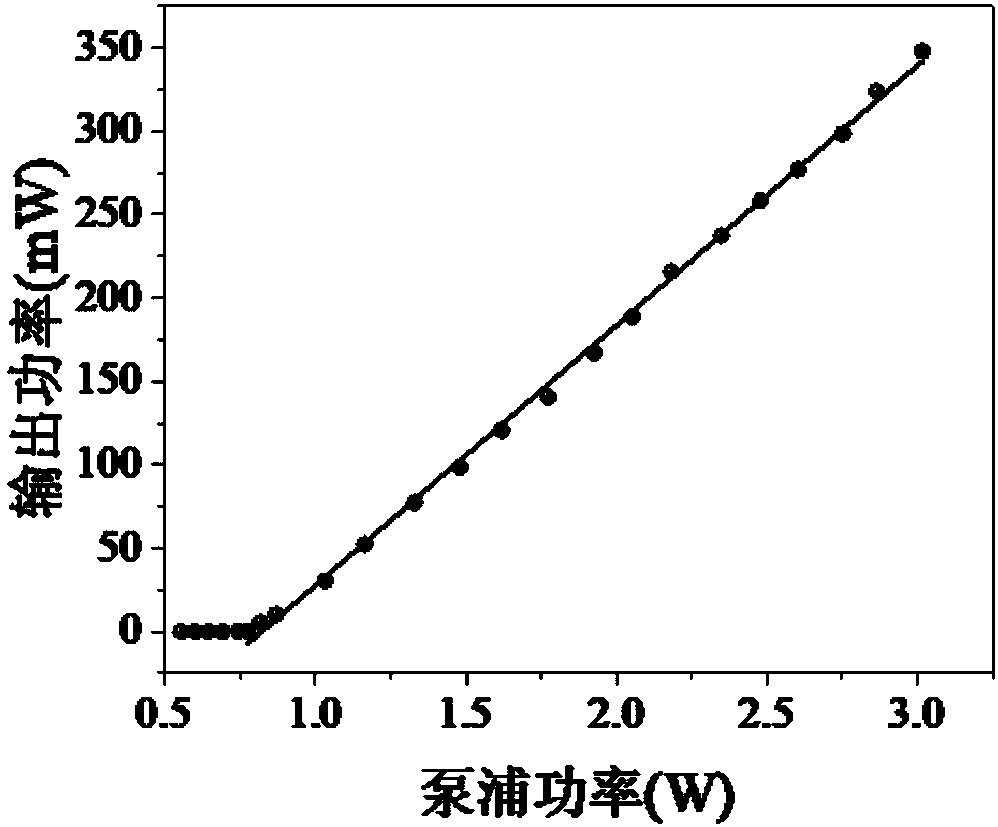

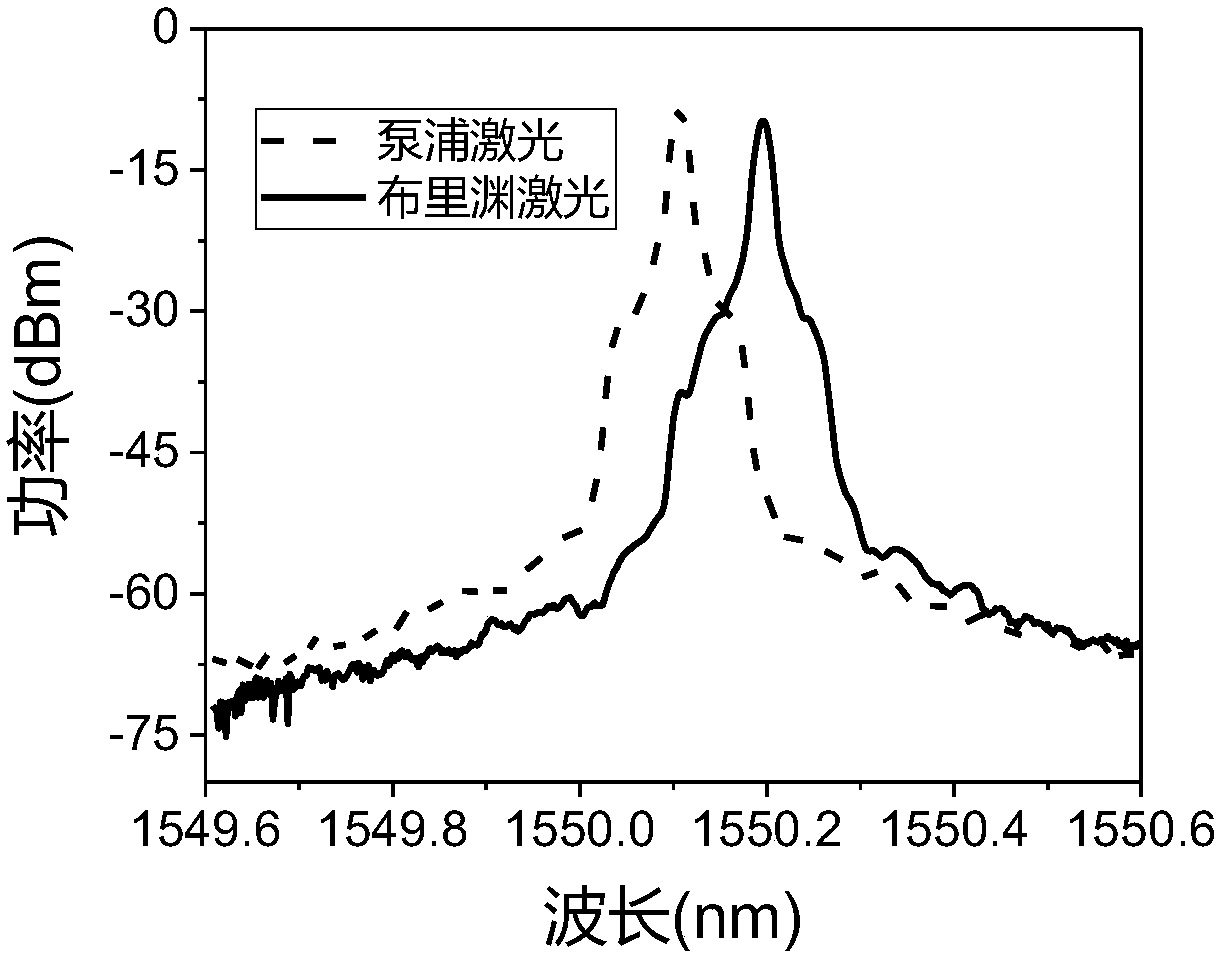

[0034] An all-fiber high-order mode Brillouin fiber laser, the schematic diagram is as follows figure 1shown. The narrow-linewidth pump laser 1 uses a 1550nm-band narrow-linewidth single-frequency fiber laser with a linewidth of 10kHz and a laser power of 30mW. Optical amplifier 2 adopts commercial 1550nm band semiconductor optical amplifier, and the amplification power can reach 5W. The optical fiber circulator 4 adopts a commercial three-port single-mode optical fiber circulator. The first fiber mode selective coupler 5 and the second fiber mode selective coupler 8 are both 2×2 couplers made of ordinary communication single-mode fiber SMF-28e and commercial two-mode step fiber fused taper, single-mode fiber The conversion efficiency of the LP01 mode in the two-mode step fiber to the LP11 mode in the fiber is 90%. The single-mode fibers in the optical path are all SMF-28e fibers. The length of the two-mode step fiber in the ring cavity is 50m, and the length of the single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com