Motor apparatus and motor driving circuit

A motor drive and motor technology, which is applied in the field of high-performance motor devices and motor drive circuits, can solve the problems of long starting time and excessive motor current, and achieve the effect of reducing temperature and avoiding damage caused by excessive current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the content of the present invention easier to understand, the following specific examples are given as examples in which the present invention can actually be implemented. In addition, wherever possible, elements / components / steps with the same reference numerals are used in the drawings and embodiments to represent the same or similar parts.

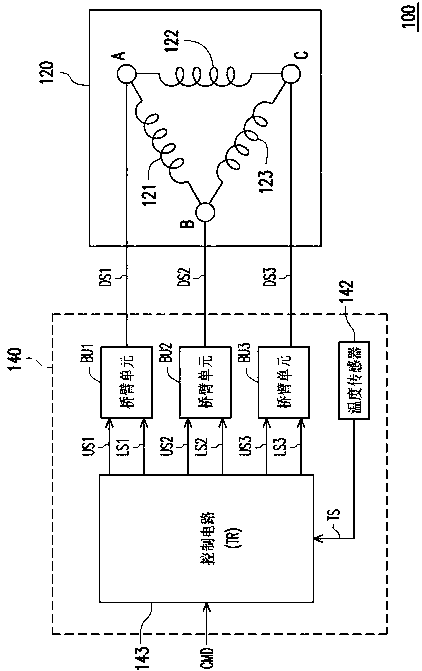

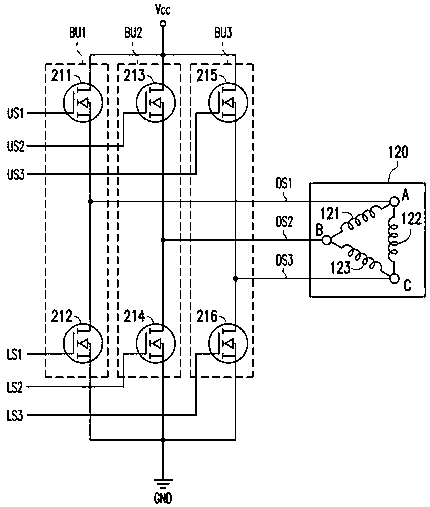

[0071] The motor device proposed in the following embodiments of the present invention can be applied to electrical products such as grinders, hair dryers, range hoods, vacuum cleaners, fans, etc., but is not limited thereto. Please refer to the following figure 1 , figure 1 It is a schematic circuit block diagram of the motor device 100 according to an embodiment of the present invention. The motor device 100 may include a motor module 120 and a motor driving circuit 140 , wherein the motor module 120 may be a multi-phase AC motor module, and the present invention does not limit the number of phases of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com