Personalized acetabular-bone posterior-column screw-setting drill die prepared through 3D printing and preparation method thereof

A 3D printing, posterior column technology, applied in bone drill guidance, computer-aided planning/modeling, surgical navigation systems, etc., can solve the problems of complicated operation steps, poor positioning accuracy retention, and high requirements for planners, to improve surgery. Effectiveness of efficiency, guaranteed accuracy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

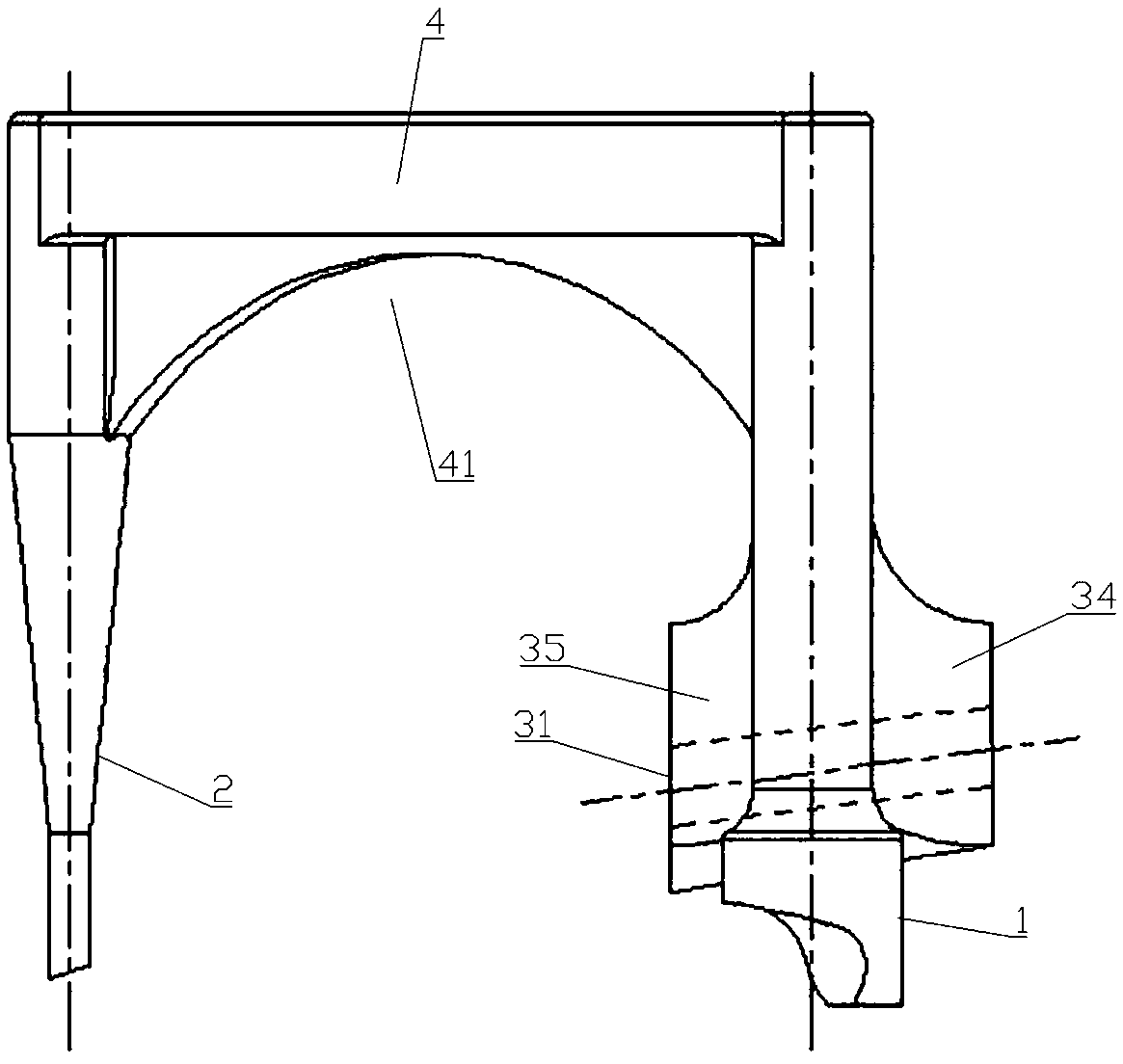

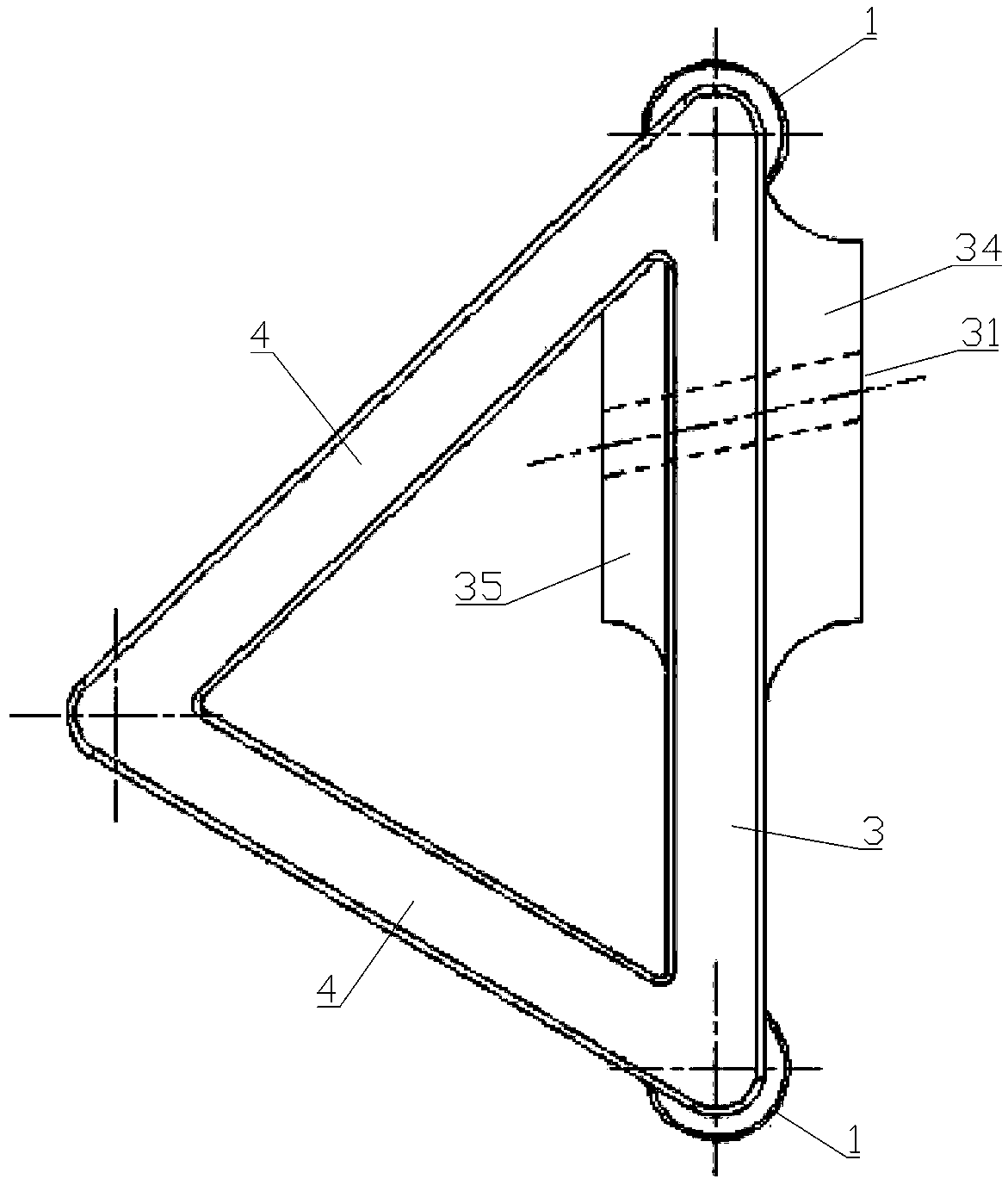

[0090] Such as Figure 1-5 As shown, the 3D-printed personalized acetabular postcolumn drill template includes a body with a triangular frame structure. The body includes two main positioning feet 1, one auxiliary positioning foot 2, one main support wall 3 and two auxiliary support walls 4.

[0091] The two main positioning feet 1 are parallel and vertically arranged and connected as a whole through the main supporting wall 3. The auxiliary positioning feet 2 are parallel and vertically arranged with the main positioning feet 1 and are respectively supported by an auxiliary support between the two main positioning feet 1. Wall 4 is connected as one.

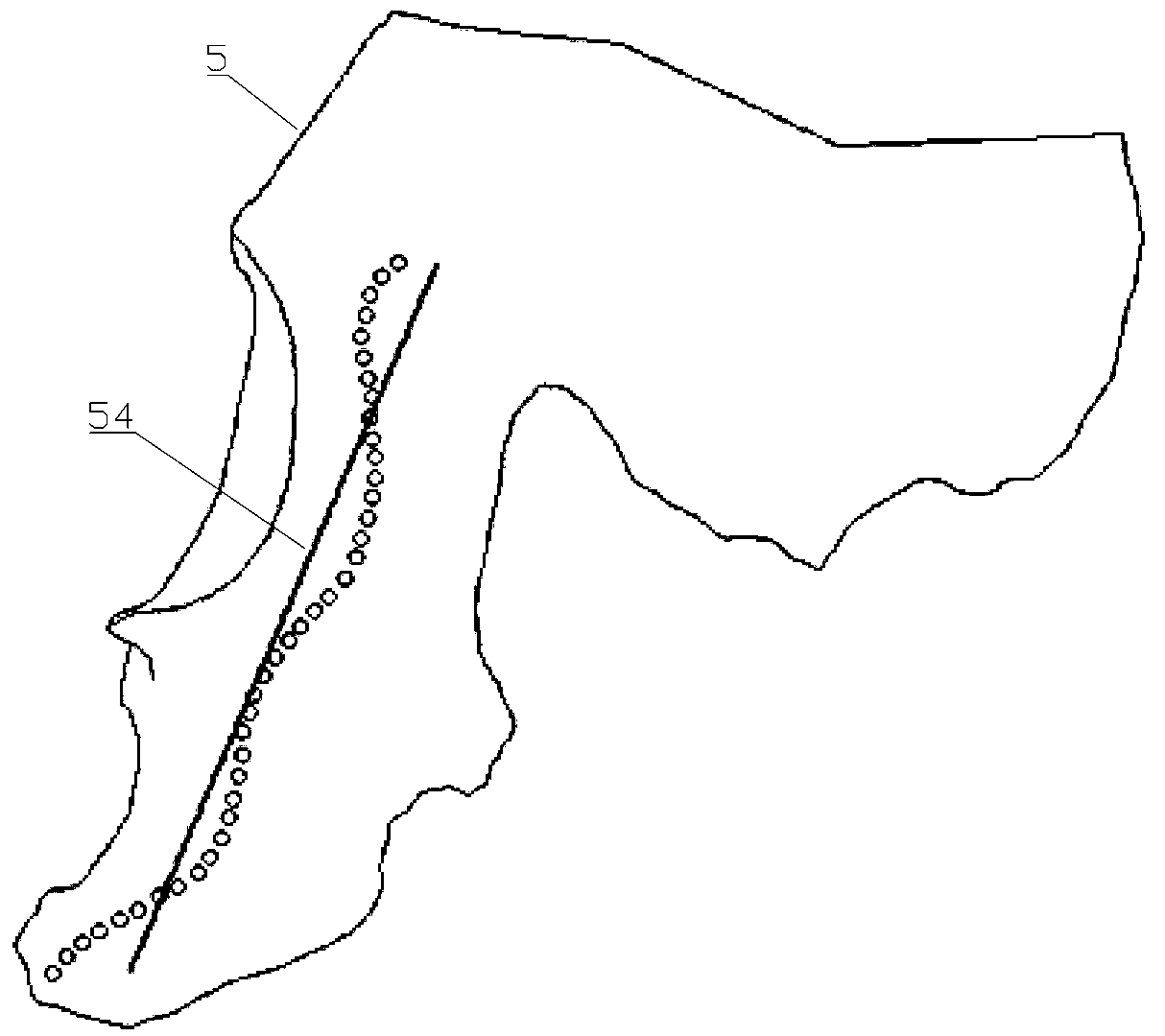

[0092] The main support wall 3 has an irregular polygonal structure, on which there is a guide jig channel 31 that runs through its inner and outer surfaces, and the lower ends of the joints between it and the two main positioning feet 1 are respectively provided with iliac wing chamfers 32. The lower ends of the two main pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com