Storage type water heater anticorrosion device, control method and water heater

A technology for anti-corrosion devices and water heaters, applied in fluid heaters, lighting and heating equipment, mechanical equipment, etc., can solve problems such as peeling, inability to completely block direct contact between water and carbon steel, uneven coating, etc., to achieve convenient replacement, The effect of avoiding the deterioration of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

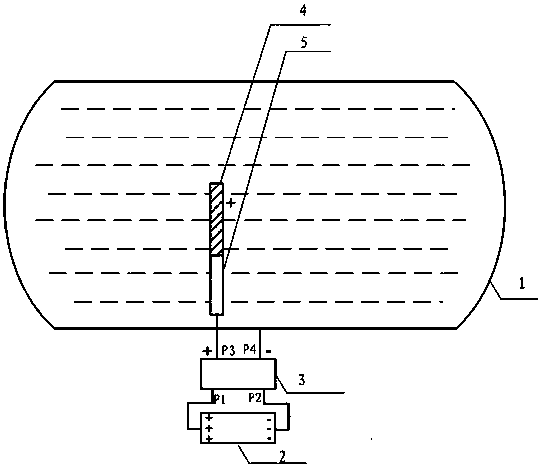

[0024] The storage type water heater anticorrosion device that this application proposes, such as figure 1 As shown, it includes water tank 1, battery 2, electronic control chip 3, auxiliary electrode 4 and reference electrode 5; auxiliary electrode 4 and reference electrode 5 are welded together and placed inside water tank 1; and reference electrode 5 and water tank 1 The connection is fixed, and the reference electrode 5 provides the water tank potential measurement reference; the electronic control chip 3 leads to a first pin P1, a second pin P2, a third pin P3 and a fourth pin P4, wherein the first pin P1 and the second pin P2 are respectively connected to the positive and negative poles of the battery, the third pin P3 is electrically connected to the reference electrode 5, and the fourth pin P4 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com