Catalyst co for hydrogen production by electrolysis of water 9 the s 8 and its preparation method

A catalyst, water electrolysis technology, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of restricting the development path of industrialization, high price, etc., and achieve the effect of broad space, high activity and stability, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

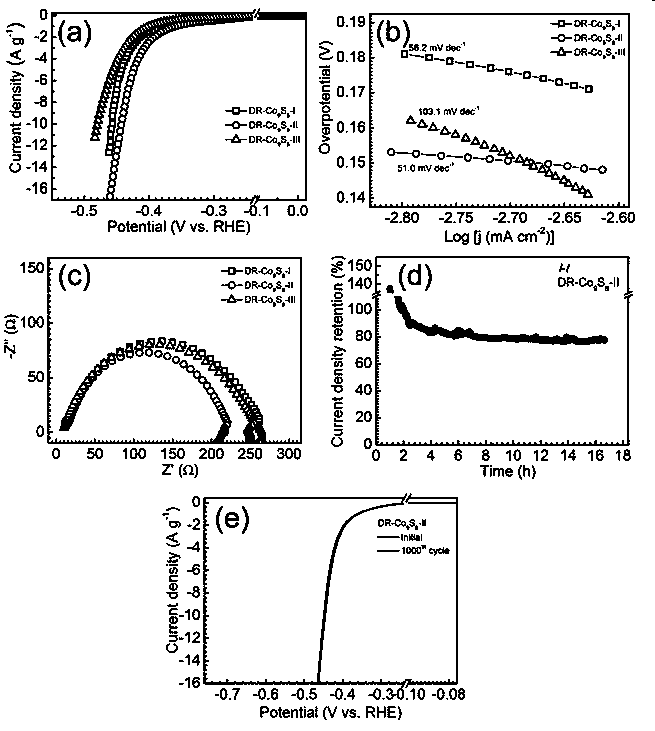

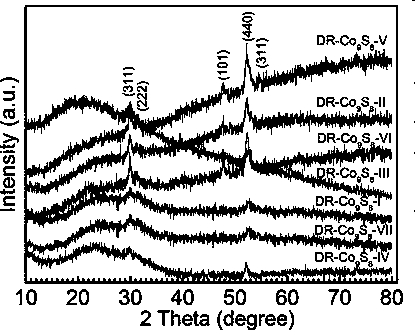

[0025] Catalyst DR-Co 9 S 8 -The preparation method of I, step is as follows:

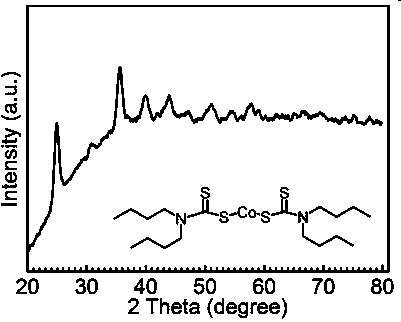

[0026] The first step, the precursor N,N - the preparation of cobalt di-n-butyldithiocarbamate, adopts and N,N -The same preparation method of zinc di-n-butyl dithiocarbamate (Guoxing Zhu, Shuguang Zhang, Zheng Xu, Jing Maand Xiaoping Shen, Ultrathin ZnS Single Crystal Nanowires: Controlled Synthesis and Room-Temperature Ferromagnetism Properties, J. Am. Chem. Soc.2011, 133, 15605–15612), the only difference is that the zinc source is replaced by a cobalt source, and the specific steps are:

[0027] Put 80 mL of methanol in an ice-water bath, then add 2.64 g of NaOH and 11 ml of dibutylamine to the methanol, then add 3.96 ml of CS 2 Add dropwise to the above solution, and then add 80 ml of 0.42 M CoSO 4 ·7H 2 O solution, magnetically stirred for 8 h, filtered with suction, and then washed with ultrapure water three times, vacuum-dried at room temperature, and collected the dried product; 2.42...

Embodiment 2

[0030] The difference from Example 1 is that the reflux time in the second step is 7 h, and the others are the same as in Example 1.

[0031] The resulting target product number is DR-Co 9 S 8 -II.

Embodiment 3

[0033] The difference from Example 1 is that the reflux time in the second step is 14 h, and the others are the same as in Example 1.

[0034] The resulting target product number is DR-Co9 S 8 -III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com