Multifunctional carbon dioxide injection enhanced oil recovery anticorrosion structure and method

A carbon dioxide and recovery factor technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well valve devices, etc., can solve the problems of increasing the cost of oil and gas production, not adjusting the injection plan, etc. Flexibility and convenience, the effect of preventing reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

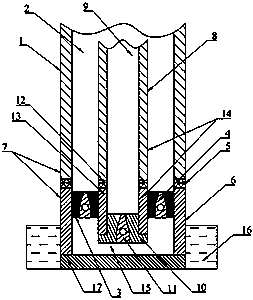

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the multi-functional carbon dioxide injection anticorrosion method for enhanced oil recovery will be described below in conjunction with accompanying drawing 1, and its detailed implementation method is as follows:

[0028] Step 1: Determine the appropriate injection scheme according to the actual working conditions, that is, CO 2 Gas continuous injection, single slug injection, CO 2- Alternate injection of water, CO 2 -Water is injected at the same time.

[0029] Step 2: After determining the injection plan, inject CO into the first channel 2 and the second channel 9 respectively in the corresponding order 2 and water, or inject water and CO into the first channel 2 and the second channel 9 respectively 2 .

[0030] Step 3: The fluid in the two channels is unidirectionally injected into the fluid collection area 15 through the first one-way valve 4 and the second one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com