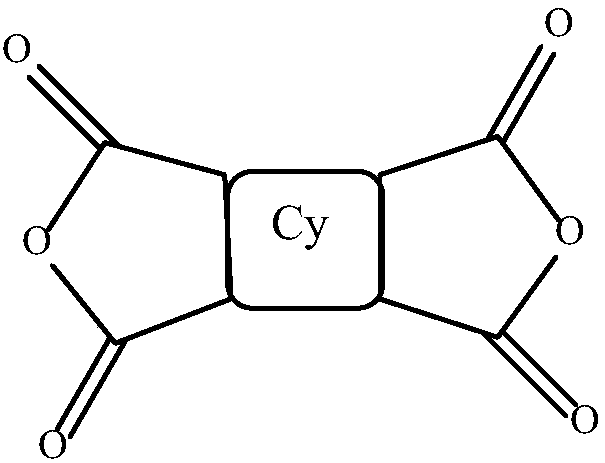

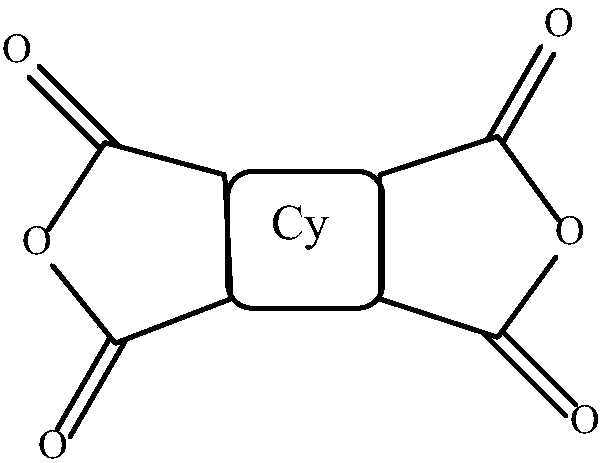

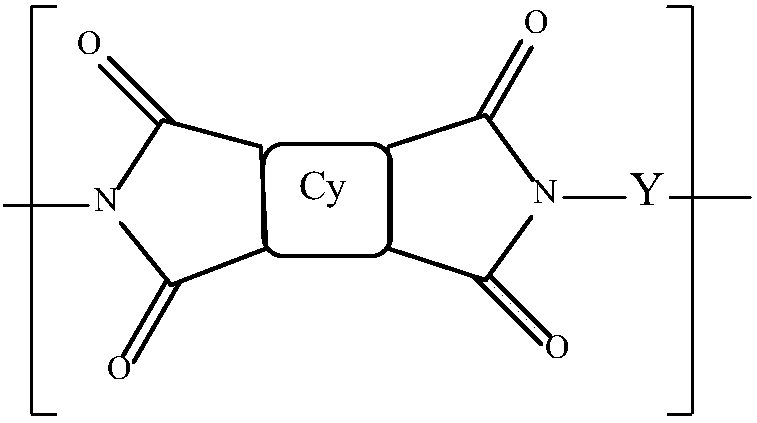

Polyamic acid composition to which alicyclic monomers are applied and transparent polyimide film using same

A polyamic acid and polyimide resin technology, applied in the field of polyamic acid composition, can solve the problems of easy bending or twisting, low permeability, high thermal expansion coefficient, and achieve the effect of excellent physical properties and product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] 1. Manufacture of transparent polyamic acid composition

[0096] More specifically, after charging 58.504 g (85.0 wt%) of N,N-dimethylacetamide (DMAc) into a 100 ml three-neck round bottom flask, the temperature of the reaction vessel was raised to 50° C., and 2,2’ -bis(trifluoromethyl)-4,4'-diaminobiphenyl (2,2'-TFDB) 3 g (4.3 wt%) and after 30 minutes, bis(4-aminophenyl)sulfone (4, 4'-DDS) 1.551 g (2.3 wt%). Then, the corresponding monomers were stirred for 1 hour to completely dissolve 2,2'-TFDB and 4,4'-DDS. After that, 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropanedianhydride (2,2-bis(3,4-dicarboxyphenyl)Hexa fluoropropanedianhydride, 6-FDA) and cyclobutanetetracarboxylic acid di After adding 4.855g (7.1wt%) and 0.919g (1.3wt%) of anhydride (CBDA) successively, it cooled to 30 degreeC and dissolved it. The solid content at this time was 15%, and it stirred for 3 hours after that. After completion of the reaction of the monomer, it was naturally cooled to obtain ...

Embodiment 2

[0100] 1. Manufacture of transparent polyamic acid composition

[0101] According to the same conditions as those mentioned in Example 1 above, after charging 54.114 g (85.0 wt%) of N,N-dimethylacetamide (DMAc) in the round bottom flask, the temperature of the reaction vessel was raised to 50°C, add 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl (2,2'-TFDB) 3g (4.7wt%) and after 30 minutes, add bis(4- Aminophenyl)sulfone (4,4'-DDS) 1.551 g (2.4 wt%). Then, the corresponding monomers were stirred for 1 hour to completely dissolve 2,2'-TFDB and 4,4'-DDS. After that, 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (2,2-bis(3,4-dicarboxyphenyl)Hexafluoropropane dianhydride, 6-FDA) and cyclobutane tetracarboxylic acid di After adding 3.468g (5.5wt%) and 1.531g (2.4wt%) of anhydride (CBDA) successively, it cooled to 30 degreeC and dissolved it. The solid content at this time was 15%, and it stirred for 3 hours after that. After completion of the reaction of the monomer...

Embodiment 3

[0105] 1. Manufacture of transparent polyamic acid composition

[0106] According to the same conditions as those mentioned in Example 1 above, after charging 44.833 g (85.0 wt%) of N,N-dimethylacetamide (DMAc) in the round bottom flask, the temperature of the reaction vessel was raised to 50°C, add 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl (2,2'-TFDB) 3g (5.7wt%) and after 30 minutes, add bis(4- Aminophenyl)sulfone (4,4'-DDS) 0.582g (1.1wt%). Then, the corresponding monomers were stirred for 1 hour to completely dissolve 2,2'-TFDB and 4,4'-DDS. After that, 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (2,2-bis(3,4-dicarboxyphenyl)Hexafluoropropane dianhydride, 6-FDA) and cyclobutane tetracarboxylic acid di After adding 3.641 g (6.9 wt%) and 0.689 g (1.3 wt%) of anhydride (CBDA) successively, it cooled to 30 degreeC and dissolved it. The solid content at this time was 15%, and it stirred for 3 hours after that. After completion of the monomer reaction, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com