Method for refining metal solidification structure through combination effect of magnetic field and vibration

A composite effect and metal solidification technology, applied in the field of metal solidification, can solve the problems of poor refinement effect, uneven solidification structure, high energy consumption in the external field, etc., and achieve improved effect, high-efficiency refinement and isotropic growth, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

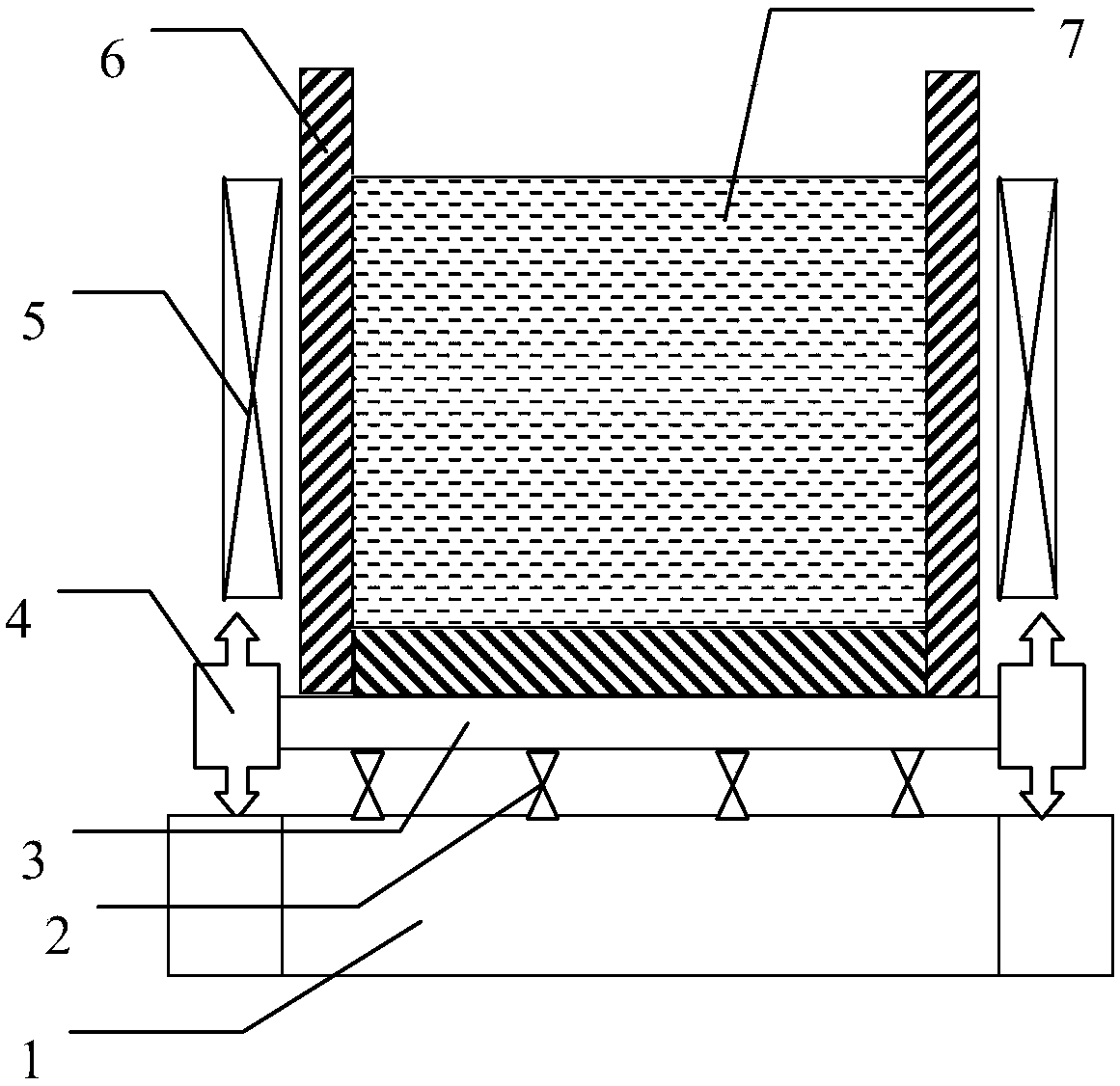

[0035] Example 1: Solidification of Aluminum Alloys in a Graphite Form

[0036] Melt preparation: 1kg of 6063 aluminum alloy, 99.7% melted at 720°C;

[0037] Casting mold: Electrode graphite casting mold, baked to 400°C, the size of the graphite casting mold is Φ160×150mm;

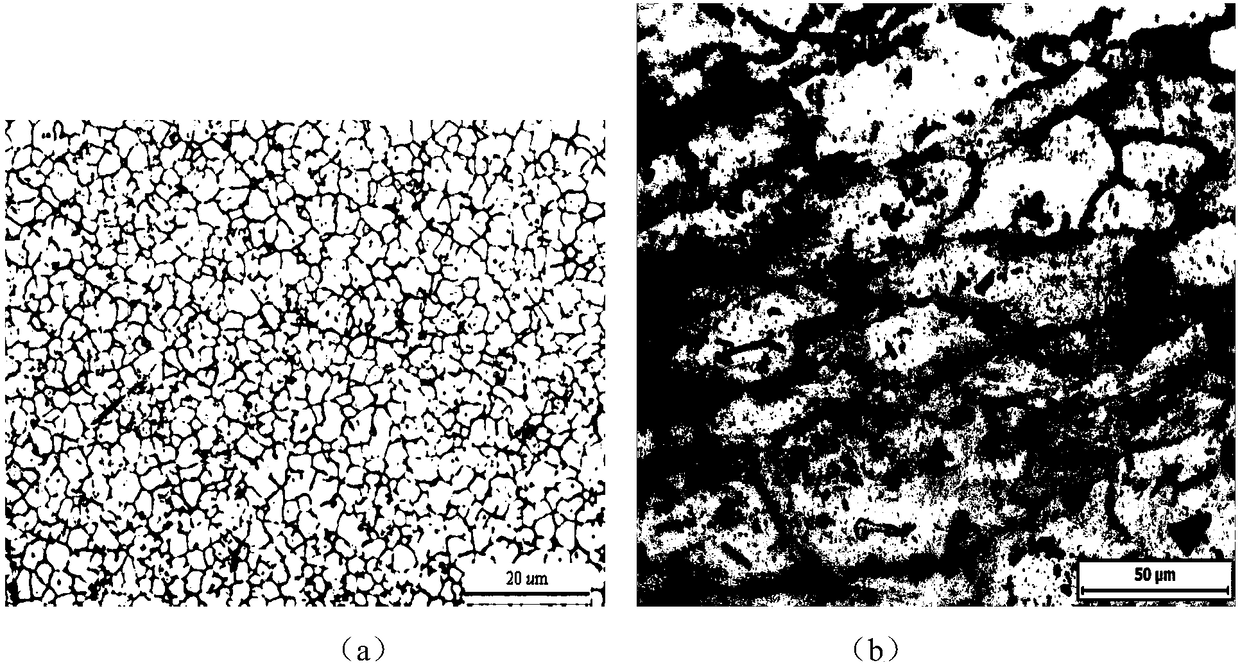

[0038]Solidification process: Place the casting mold directly on the vibration device, the vibration device and the support platform are connected by a flexible device, and the vibration device is driven by a high-frequency motor; after the aluminum alloy melt is degassed, when the temperature drops to 700 ° C, the aluminum The alloy melt is poured into the mold and starts to vibrate, so that the mold and the metal melt inside vibrate vertically along with the vibrating device. The vibration frequency is 400Hz and the amplitude is 10 microns. At the same time, an electromagnetic stirring coil is installed outside the mold , Turn on the electromagnetic stirring while vibrating, so that the metal melt moves...

Embodiment 2

[0041] Embodiment 2: Solidification of AZ91 magnesium alloy in copper mold

[0042] Copper casting mold: the size is Φ280×250mm;

[0043] Solidification experiment process: Place the casting mold directly on the vibrating device, the vibrating device and the support platform are connected by a flexible device, and the vibrating device is driven by a high-frequency motor; after the alloy melt is refined, the temperature drops to 610°C and is cast into the casting mold , start to vibrate, so that the mold and the molten metal inside vibrate vertically along with the vibrating device. The frequency of vibration is 500 Hz and the amplitude is 20 microns. At the same time, an electromagnetic stirring coil is installed outside the mold, and the electromagnetic stirring is turned on while vibrating , so that the metal melt moves horizontally and circumferentially to solidify under the action of electromagnetic stirring at the same time, the frequency of the current used for magnetic ...

Embodiment 3

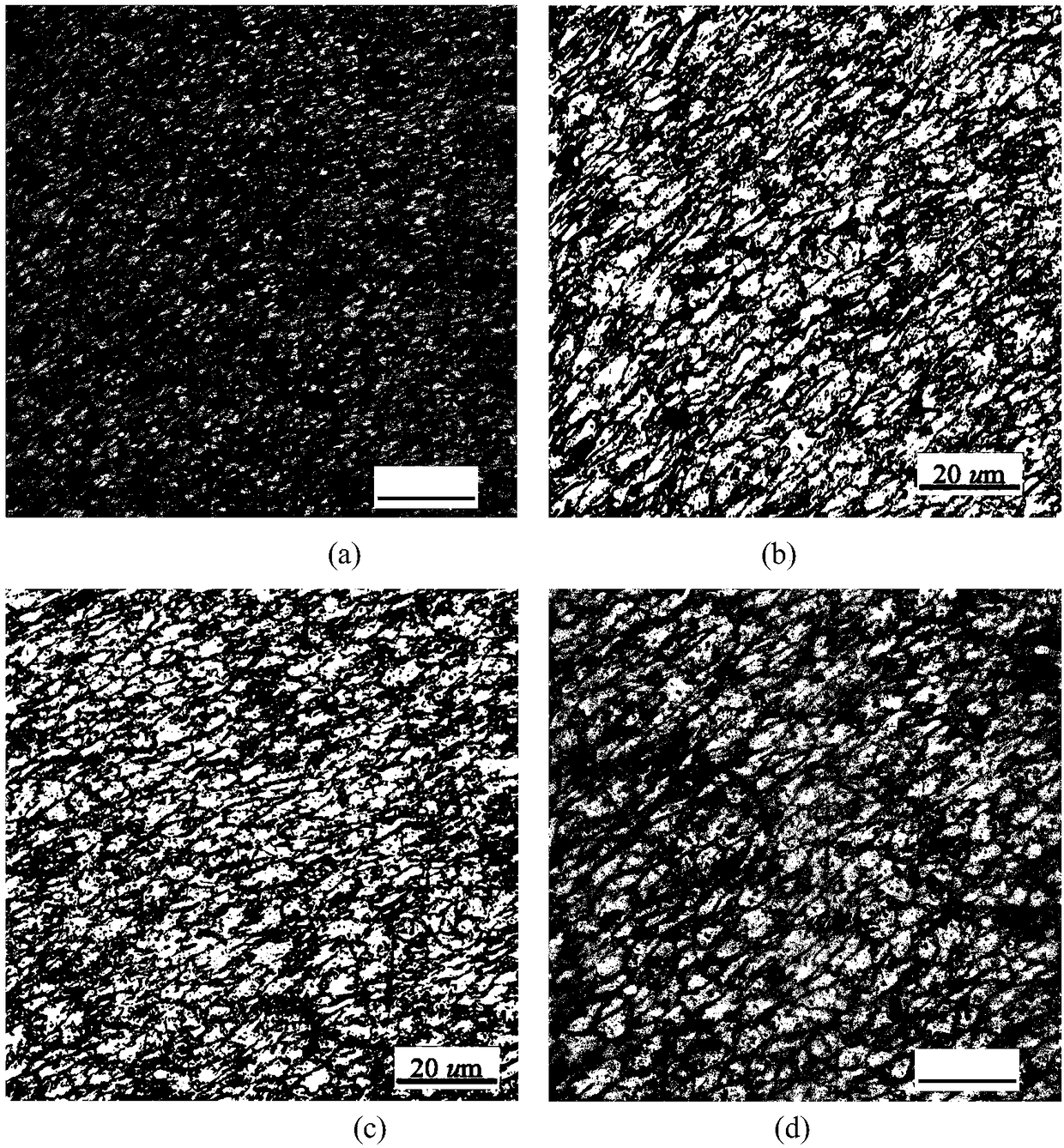

[0047] Example 3: Solidification of steel

[0048] Melt preparation: 10kg of 40Cr alloy steel was melted at 1580°C.

[0049] Casting mold: in a sand mold with a size of Φ280×250mm.

[0050] Place the casting mold directly on the vibrating device, the vibrating device and the support platform are connected by a flexible device, and the vibrating device is driven by a high-frequency motor; after the alloy melt is refined, when the temperature drops to 1520 ° C, it is poured into the casting mold and starts to vibrate. Make the casting mold and the molten metal inside vibrate vertically along with the vibrating device. The frequency of the vibration is 200Hz and the amplitude is 45 microns. At the same time, the melt moves horizontally and circumferentially under the action of electromagnetic stirring until solidification. The frequency of the current used for magnetic stirring is 6Hz, and the magnetic induction intensity in the melt is 400Gs. Until it is completely solidified, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com