Lithium battery anode and preparation method thereof, and lithium battery

A lithium battery and negative electrode technology, which is applied in the lithium battery negative electrode and its preparation, and in the field of lithium batteries, can solve the problems of less reports on in-situ growth behavior, and achieve the effects of no pollution at the interface, elimination of growth, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

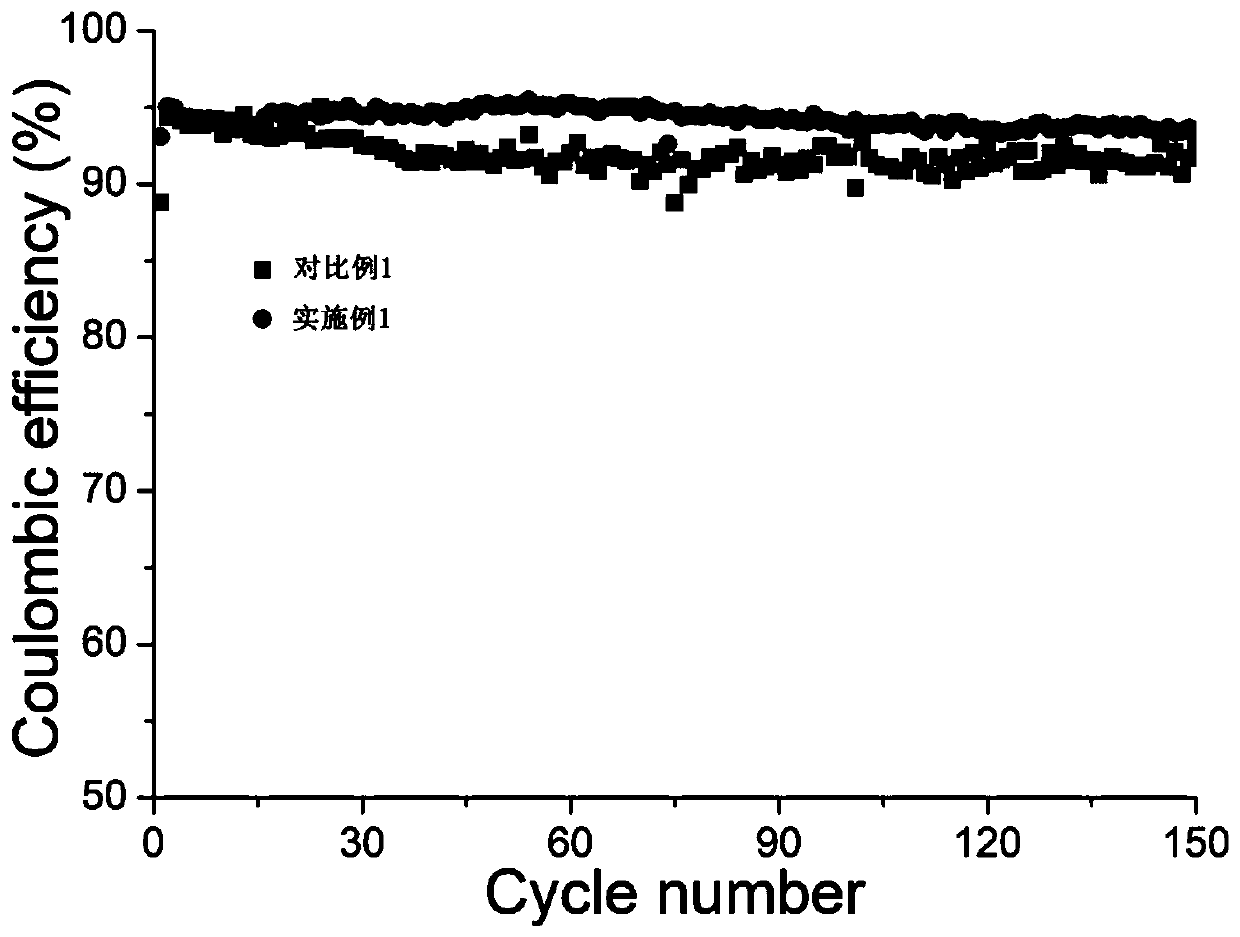

Embodiment 1

[0034] Preparation of negatively charged inorganic nanosheets:

[0035] S1, take 100 mg of commercial expanded vermiculite, after cleaning and drying, first reflux in 50 ml of saturated sodium chloride solution at 80 °C for 12 hours, then repeat centrifugation to collect the precipitate, and wash until there is no Cl- in the solution;

[0036] S2, put the precipitate of S1 in 2mol / L LiCl aqueous solution, reflux at 80°C for 12h, then repeat centrifugation to collect the precipitate and wash until there is no Cl- in the solution;

[0037] S3, put the precipitate of S2 in 50ml of 30wt.% hydrogen peroxide, reflux at 80°C for 12h, and finally ultrasonicate the solution for 12h, centrifuge at 5000r / min to get the supernatant, and then re-centrifuge the supernatant at 10000r / min Centrifuge at a rotating speed of 1.5 nm to obtain peeled vermiculite nanosheets with a thickness of 1.5 nm, freeze-dry and set aside.

[0038] Preparation of lithium battery negative electrode and lithium ...

Embodiment 2

[0043] Preparation of negatively charged inorganic nanosheets:

[0044] S1, take 100 mg of commercial expanded vermiculite, after cleaning and drying, first reflux in 50 ml of saturated sodium chloride solution at 80 °C for 12 hours, then repeat centrifugation to collect the precipitate, and wash until there is no Cl- in the solution;

[0045] S2, put the precipitate of S1 in 2mol / L LiCl aqueous solution, reflux at 80°C for 12h, then repeat centrifugation to collect the precipitate and wash until there is no Cl- in the solution;

[0046] S3, put the precipitate of S2 in 50ml of 30wt.% hydrogen peroxide, reflux at 80°C for 12h, and finally ultrasonicate the solution for 12h, centrifuge at 5000r / min to get the supernatant, and then re-centrifuge the supernatant at 10000r / min Centrifuge at a rotating speed of 1.5 nm to obtain peeled vermiculite nanosheets with a thickness of 1.5 nm, freeze-dry and set aside.

[0047] Preparation of lithium battery negative electrode and lithium ...

Embodiment 3

[0052] Preparation of negatively charged inorganic nanosheets:

[0053] S1, take 500 mg of bentonite, after cleaning and drying, first reflux in 100 ml of saturated sodium chloride solution at 70°C for 15 hours, then repeat centrifugation to collect the precipitate, and wash until there is no Cl- in the solution;

[0054] S2, put the precipitate of S1 in 3mol / L LiCl aqueous solution, reflux at 80°C for 12h, then repeat centrifugation to collect the precipitate, and wash until there is no Cl- in the solution;

[0055] S3, put the precipitate of S2 in 50ml of 30wt.% hydrogen peroxide, reflux at 70°C for 15h, and finally ultrasonicate the solution for 12h, centrifuge at 5000r / min to get the supernatant, and then re-centrifuge the supernatant at 10000r / min Centrifuge at a rotating speed of 4.5 nm to obtain bentonite nanosheets with a thickness of 4.5 nm, which are freeze-dried for subsequent use.

[0056] Preparation of lithium battery negative electrode and lithium battery:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com