Composite separator, fabrication method thereof and lithium ion battery

A composite diaphragm and electrical insulation technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as explosion, battery positive and negative short circuit, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

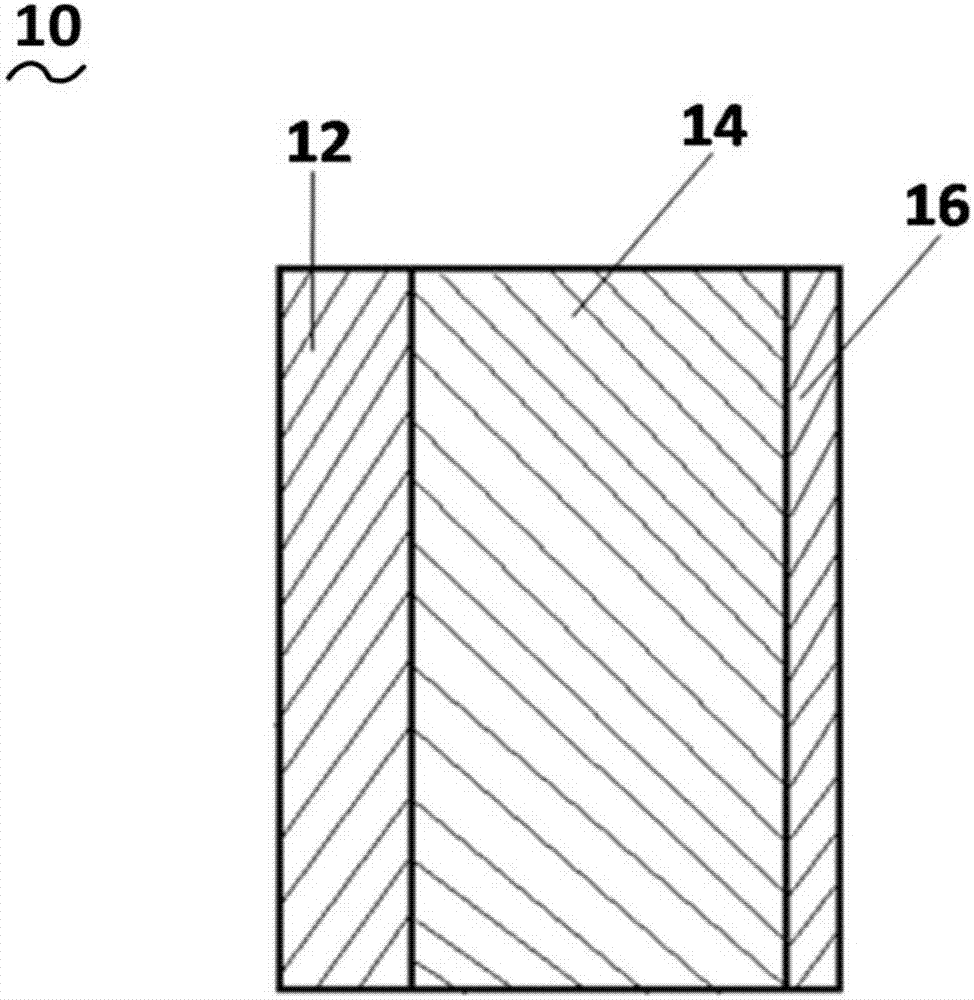

[0045] The present invention also provides a preparation method of the composite diaphragm 10, comprising:

[0046] S110, prepare the conductive fiber layer 12; and

[0047] S120 , forming an electrically insulating nanofiber layer 14 on the conductive fiber layer 12 .

[0048] Preferably, further comprising:

[0049] S130 , forming an inorganic nanolayer 16 on the electrically insulating nanofiber layer 14 .

[0050] In one of the embodiments, S110 further includes:

[0051] S112, providing a first polymer solution;

[0052] S114, making the first polymer solution into a nanofiber film by electrospinning; and

[0053] S116 , carbonizing the nanofiber film to obtain the conductive fiber layer 12 .

[0054] In step S112, the first polymer solution is preferably at least one of polyamic acid solution and polyacrylonitrile solution. The solvent in the first polymer solution may be at least one of N,N-dimethylformamide, dimethylacetamide, acetone, tetrahydrofuran, N-methylpy...

Embodiment 1

[0082] S110, prepare the conductive fiber layer 12 nanometer carbon fiber layer, including:

[0083] S112, using biphenyltetracarboxylic dianhydride (BPDA) and p-phenylenediamine (PPD), synthesize a polyamic acid solution with a mass percentage of 6% in N, N-dimethylformamide solution at -5°C ;

[0084] S114, preparing a polyamic acid nanofiber membrane by an electrospinning method. Specifically, the polyamic acid solution obtained in step S112 is added to the syringe pump, and the ambient humidity is controlled to be 30%; the syringe pump is connected to the spinning needle through a pipeline; the distance between the needle and the receiving device is 30 cm, and 25 kV is applied between the two. High-voltage electricity; through the pipeline from the syringe pump to the polymer solution in the spinning needle, the polyamic acid nanofibers are sprayed at a flow rate of 1mL / h; the polyamic acid nanofibers are collected using a receiving device to obtain polyamic acid with a t...

Embodiment 2

[0094] S110, prepare the conductive fiber layer 12 nanometer carbon fiber layer, including:

[0095] S112, preparing a polyacrylonitrile solution with a mass percentage of 15%, using N, N dimethylformamide as a solvent;

[0096] S114, preparing a polyamic acid nanofiber membrane by an electrospinning method. Add the polyacrylonitrile solution to the syringe pump, and control the ambient humidity to 50%; the syringe pump is connected to the spinning needle through a pipeline; the distance between the needle and the receiving device is 20cm, and a high voltage of 35kV is applied between the two; Polyacrylonitrile nanofibers are sprayed out from the polymer solution in the spinning needle from the syringe pump at a flow rate of 2mL / h; the polyacrylonitrile nanofibers are collected using a receiving device to obtain a polyacrylonitrile nanofiber film with a thickness of 20 μm;

[0097] S116a, preoxidizing the polyacrylonitrile nanofiber membrane to obtain a treated polyacrylonitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com