Humidifying device and method for block materials

A technology of bulk material and humidification device, which is applied in the direction of injection device, liquid injection device, loading/unloading, etc., can solve the problems of secondary dust, environmental pollution, increase investment in smoke and dust control, etc., to achieve recycling and solve secondary problems The effect of raising dust and ensuring the moisture content of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

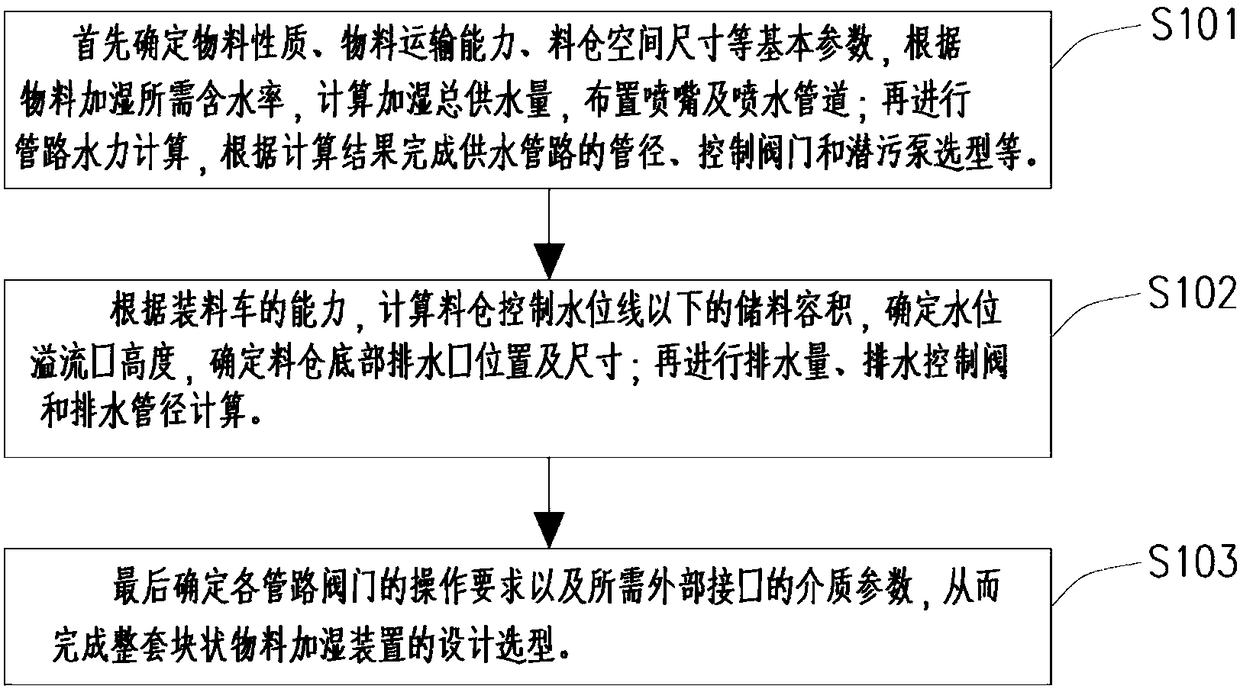

Method used

Image

Examples

Embodiment Construction

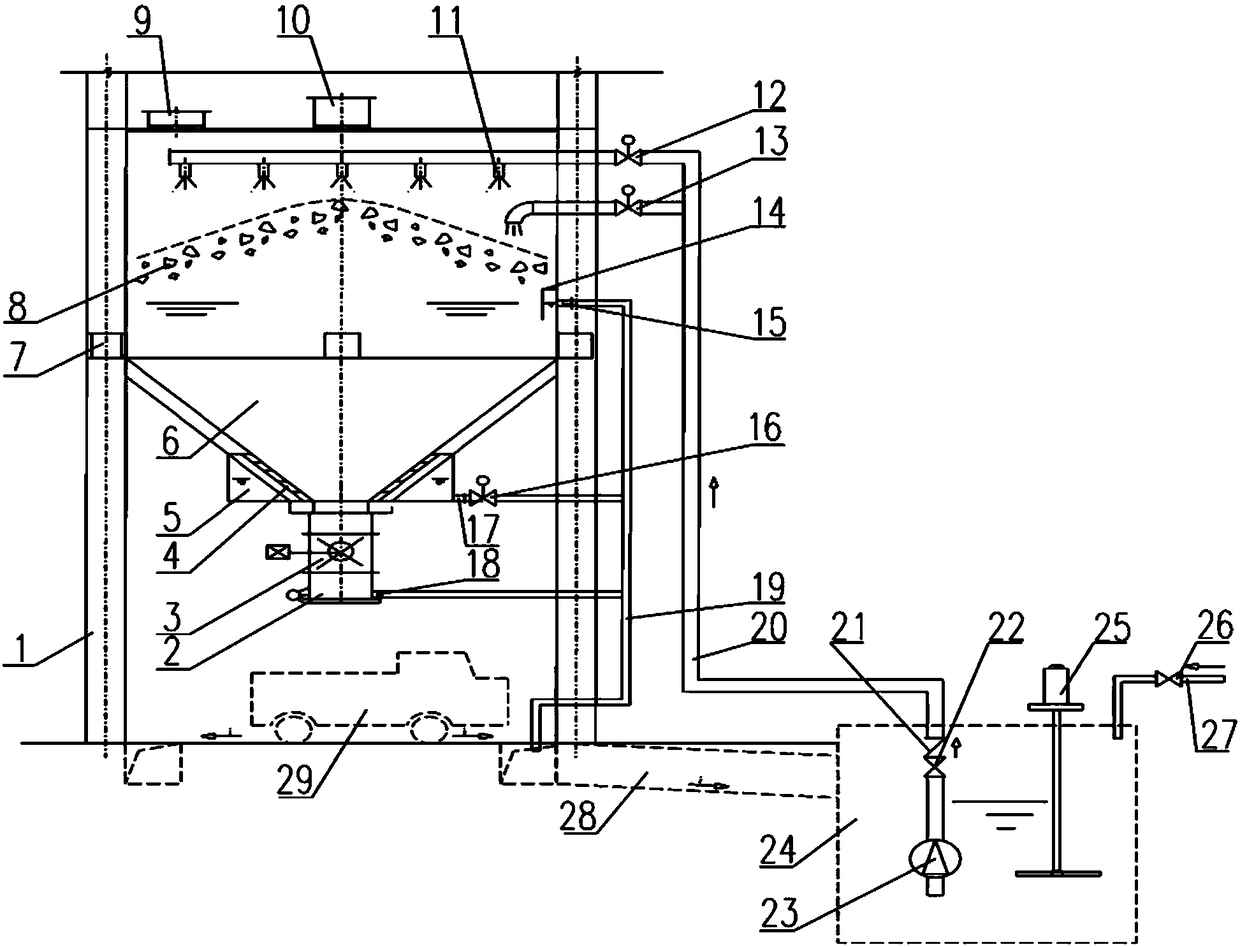

[0037] The humidifying device of the present invention comprises: discharging port drain valve 2, discharging valve 3, wear-resistant orifice plate 4, annular water tank 5, silo 6, exhaust port 9, feeding port 10, nozzle 11, electric water supply valve I12 , Electric water supply valve II13, anti-clogging plate 14, overflow port 15, electric drain valve 16, drain port I17, drain port II18, drain pipe 19, water supply pipe 20, check valve 21, gate valve 22, submersible sewage pump 23, pool 24. Stirrer 25, water supply valve 26, water supply pipe 27, drainage ditch 28, charging cart 29.

[0038] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail in conjunction with the following examples; it should be understood that the specific examples described here are only used to explain the present invention and are not intended to limit the present invention .

[0039] The embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com