Inflatable thin film method for preparing micro-nano structure of flexible thin film substrate

A technology of micro-nano structure and flexible film, which is applied in the manufacture of nano-structures, the formation of specific nano-structures, the manufacture of micro-structure devices, etc., can solve the problem that the flexible film substrate and the reticle are not tightly attached and cannot meet the high-precision requirements of micro-nano devices and other problems, to achieve the effect of high process repeatability and reliability, high consistency, and batch preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

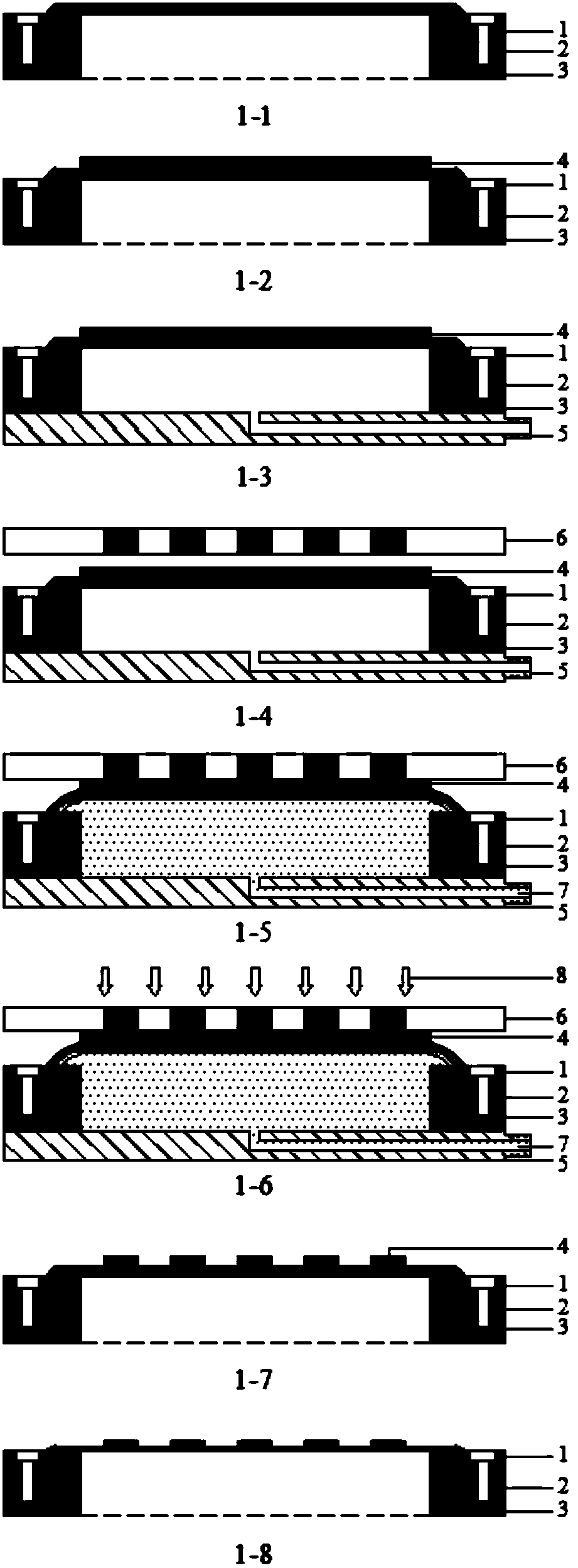

[0028] Such as figure 1 As shown in middle 1-1, the flexible film substrate 2 is fixed by two aluminum fixtures, the upper fixture 1 and the lower fixture 3, wherein the flexible film substrate 2 is a polyimide film substrate;

[0029] Such as figure 1 As shown in 1-2, AZ1500 photoresist 4 with a thickness of 600nm is evenly coated on the upper surface of the polyimide film substrate, and baked on a hot plate at 100°C for 60 seconds;

[0030] Such as figure 1 As shown in middle 1-3, fix the aluminum backboard 5 with air-filled holes on the lower fixture 3;

[0031] Such as figure 1 As shown in 1-4, take a traditional hard mask plate 6 and install it on the mask holder of the contact exposure machine, and use the lifting system of the contact exposure machine to adjust the gap between the mask plate 6 and the photoresist 4 as 40um;

[0032] Such as figure 1 As shown in 1-5, a certain volume of air 7 is filled into the sealed cavity through the air hole, and under the effe...

Embodiment 2

[0037] Such as figure 1 As shown in middle 1-1, the flexible film substrate 2 is fixed by two aluminum fixtures, the upper fixture 1 and the lower fixture 3, wherein the flexible film substrate 2 is a polyethersulfone film substrate;

[0038] Such as figure 1 As shown in 1-2, AZ3100 photoresist 4 with a thickness of 1.2um is evenly coated on the upper surface of the polyethersulfone film substrate, and baked on a hot plate at 100°C for 150 seconds;

[0039] Such as figure 1 As shown in middle 1-3, fix the aluminum backboard 5 with air-filled holes on the lower fixture 3;

[0040] Such as figure 1 As shown in 1-4, take a traditional hard mask plate 6 and install it on the mask holder of the contact exposure machine, and use the lifting system of the contact exposure machine to adjust the gap between the mask plate 6 and the photoresist 4 as 20um;

[0041] Such as figure 1 As shown in 1-5, a certain volume of air 7 is filled into the sealed cavity through the air hole, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com