Method for improving emulsifying activity of rapeseed protein

A technology of rapeseed protein and emulsifying activity, which is applied in the field of improving the emulsifying activity of rapeseed protein, and achieves the effects of short enzymatic hydrolysis time, improved emulsifying activity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for improving the emulsifying activity of rapeseed protein, the method comprising the following steps:

[0027] (1) Adjust the water content of the rapeseed meal, adjust the water content to 15%, and then perform extrusion pretreatment, the sleeve temperature is 85 ° C, and the screw speed is 600 r / min;

[0028] (2) Crush the rapeseed meal pretreated by extrusion in step (1) through a 60-mesh sieve, add water and mix to make a 5% rapeseed meal solution, adjust the pH to 2, and add 6 mg / mL Pepsin hydrolyzed for 70 minutes, cooled to room temperature after enzymolysis, and adjusted to neutral pH;

[0029] (3) Perform ultrafiltration on the enzymatic hydrolysis solution to obtain rapeseed protein with a molecular weight cut-off of 40 kDa. After the intercepted protein is concentrated and spray-dried (at an air inlet temperature of 170° C.), rapeseed protein with high emulsifying activity is obtained.

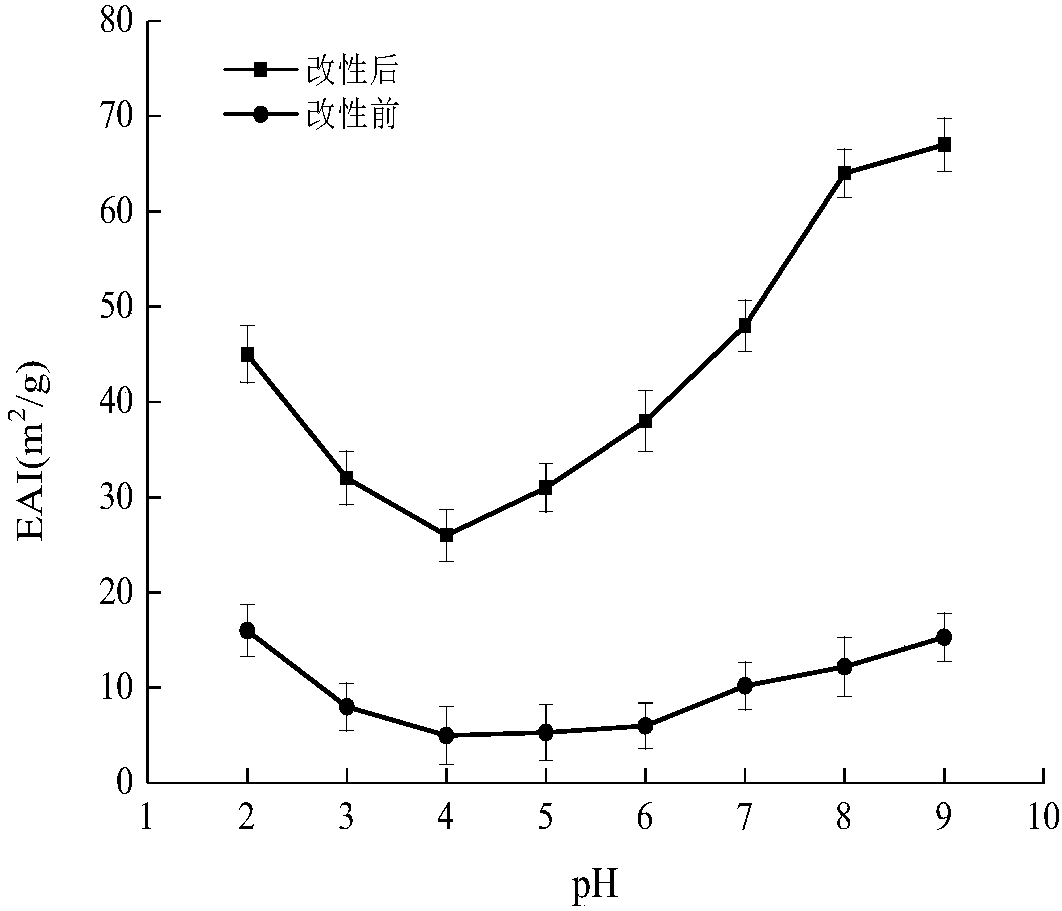

[0030] Compared with the modified rapeseed protein, the emuls...

Embodiment 2

[0032] A method for improving the emulsifying activity of rapeseed protein, the method comprising the following steps:

[0033] (1) Adjust the water content of the rapeseed meal, adjust the water content to 20%, and then carry out extrusion pretreatment, the sleeve temperature is 95 ° C, and the screw speed is 700 r / min;

[0034] (2) Grind the rapeseed meal pretreated by extrusion in step (1) through an 80-mesh sieve, add water and mix to make a 10% rapeseed meal solution, adjust the pH to 8, and add 7mg / mL Trypsin for 90min enzymolysis, after enzymolysis, cool to room temperature, adjust pH to neutral;

[0035] (3) The enzymolysis solution was subjected to ultrafiltration to obtain rapeseed protein with a molecular weight cut-off of 50 kDa, and the retained protein was concentrated and spray-dried (air inlet temperature 180° C.) to obtain rapeseed protein with high emulsifying activity.

[0036] Compared with the modified rapeseed protein, the emulsifying activity index (EAI...

Embodiment 3

[0038] A method for improving the emulsifying activity of rapeseed protein, the method comprising the following steps:

[0039] (1) Adjust the water content of the rapeseed meal, adjust the water content to 30%, and then perform extrusion pretreatment, the sleeve temperature is 150°C, and the screw speed is 800r / min;

[0040] (2) Crush the rapeseed meal pretreated by extrusion in step (1) through a 40-mesh sieve, add water and mix to make an 8% rapeseed meal solution, adjust the pH to 9, and add 8 mg / mL Alkaline protease for 120min enzymolysis, after enzymolysis, cool to room temperature, adjust the pH to neutral,

[0041] (3) The enzymolysis solution was subjected to ultrafiltration to obtain rapeseed protein with a molecular weight cut-off of 30 kDa, and the intercepted protein was concentrated and spray-dried (air inlet temperature 190° C.) to obtain rapeseed protein with high emulsifying activity.

[0042] Compared with the modified rapeseed protein, the emulsifying activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com