Construction method of cast-in-situ concrete structure external thermal insulation integrated non-removal formwork

A technology for concrete structures and formwork-free dismantling, applied in thermal insulation, building components, building structures, etc., can solve the problems of fatal defects in durability and flame retardant and fire resistance, large formwork materials and manpower, and limitations of application scope, etc. The process is standardized and simple, the effect of improving the flexural and compressive strength, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

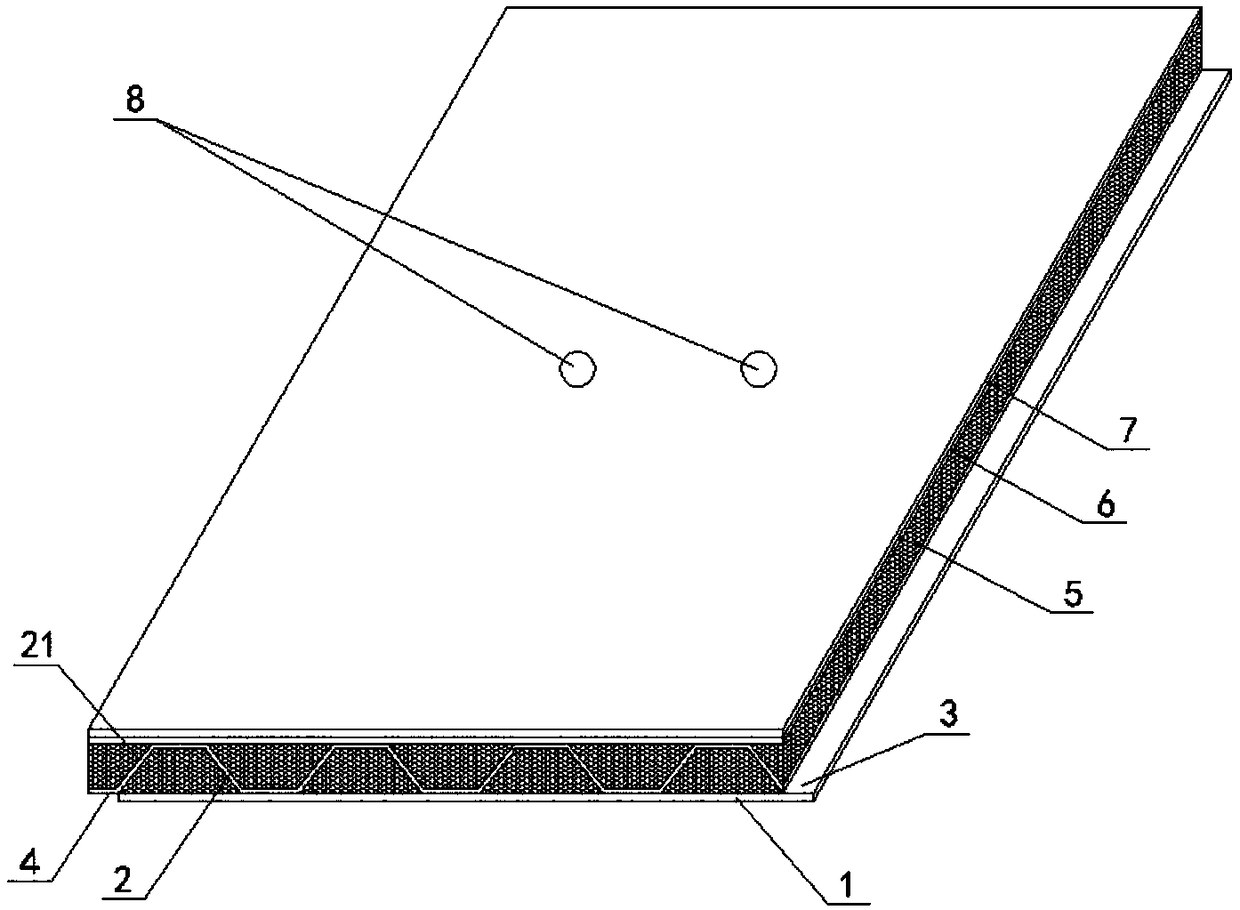

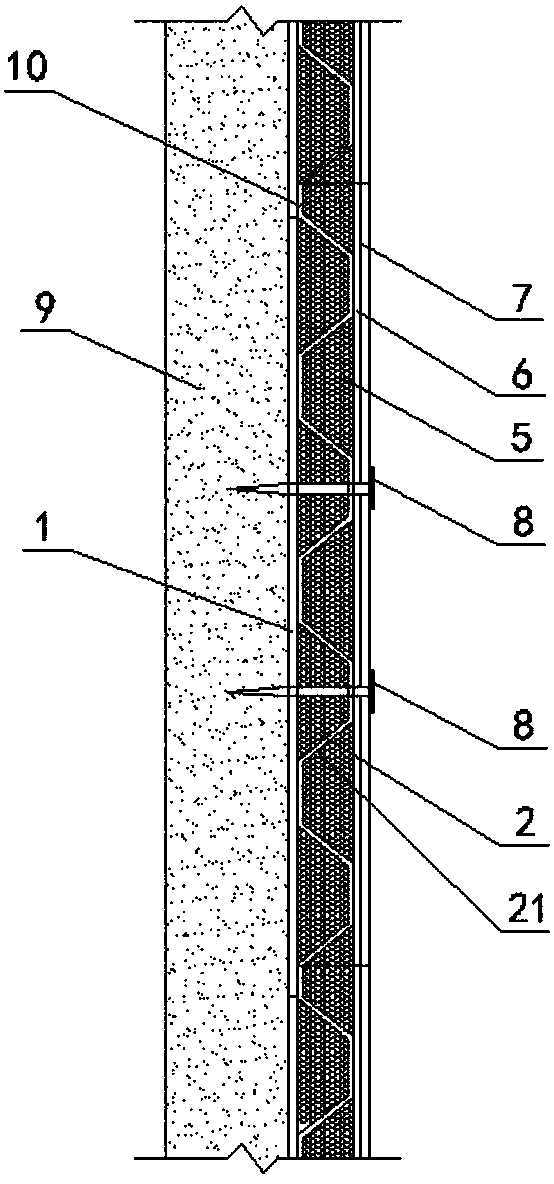

[0023] see figure 1 and figure 2 In this embodiment, the construction method of the cast-in-place concrete structure external thermal insulation integrated non-demolition formwork is: the external formwork in the construction of the cast-in-place reinforced concrete structure external wall is a non-demolition formwork with thermal insulation function, and the formwork bottom plate in the non-demolition formwork 1. Adhere to the concrete exterior wall 9, and use anchors 8 to connect with the steel bars inside the exterior wall to complete the installation of the non-demolition formwork. After the cast-in-place concrete is poured and tamped, the exterior formwork remains connected to the concrete exterior wall 9, and the exterior formwork is not required. The demolition process makes the outer formwork and the outer wall of the structure attached as a whole, so that the heat preservation and the building have the same life span. figure 2 The anchor 8 shown in is a threaded ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com