Iso-butane dehydrogenation technology and system

A technology for isobutane and dehydrogenation, which is applied in the field of isobutane dehydrogenation process and system, achieves the effects of simple structure, reduced dependence, and improved comprehensive utilization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

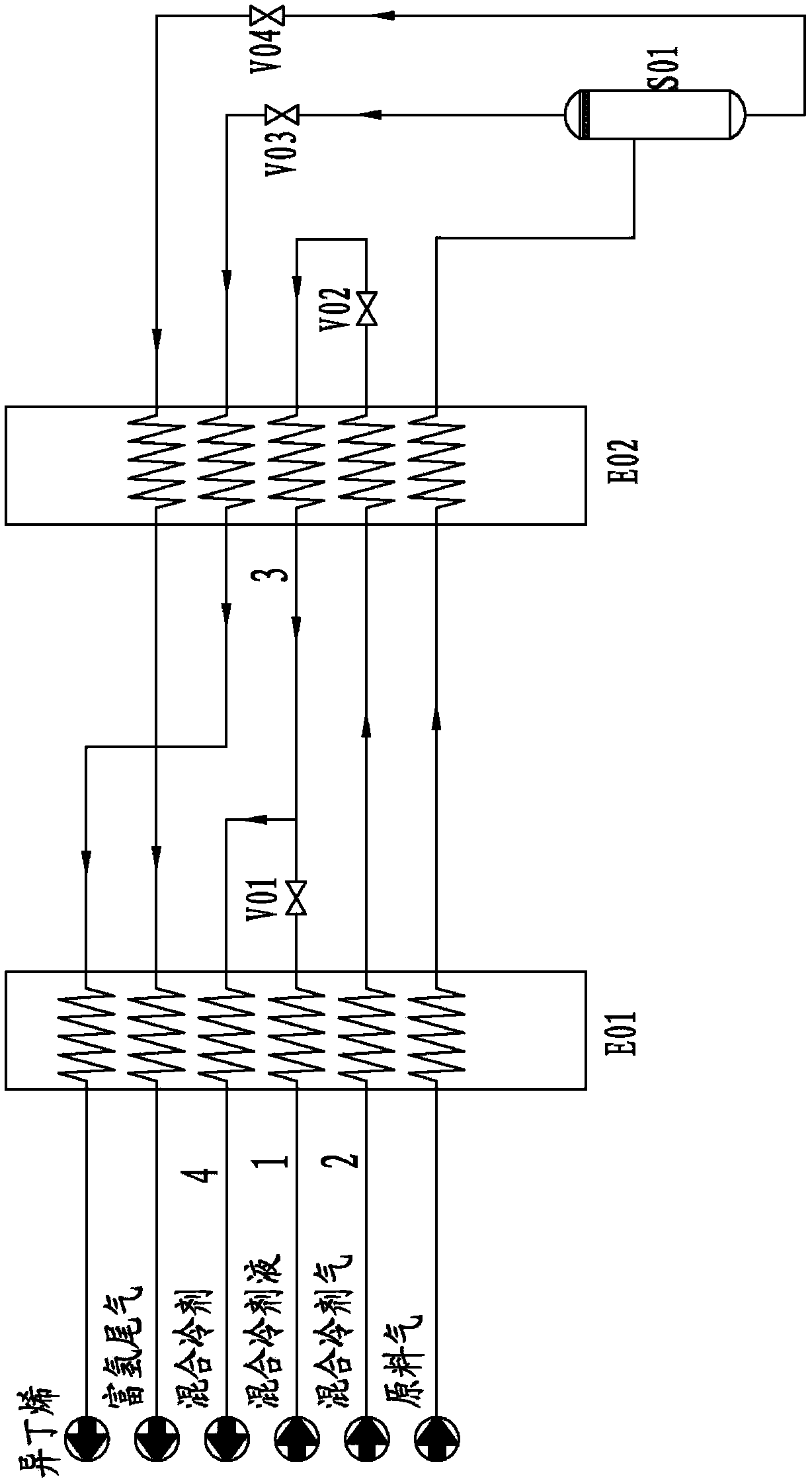

[0024] Such as figure 1 , figure 2 Shown, isobutane dehydrogenation system of the present invention comprises:

[0025] The primary heat exchanger E01 used to initially cool down the feed gas;

[0026] The secondary heat exchanger E02, which is used to cool down the raw material gas initially cooled, is connected with the primary heat exchanger E01 through pipelines;

[0027] The first gas-liquid separator S01 is used for gas-liquid separation of the raw material gas after cooling down again, so that the raw material gas is separated into hydrogen-rich gas, liquid isobutane and isobutene.

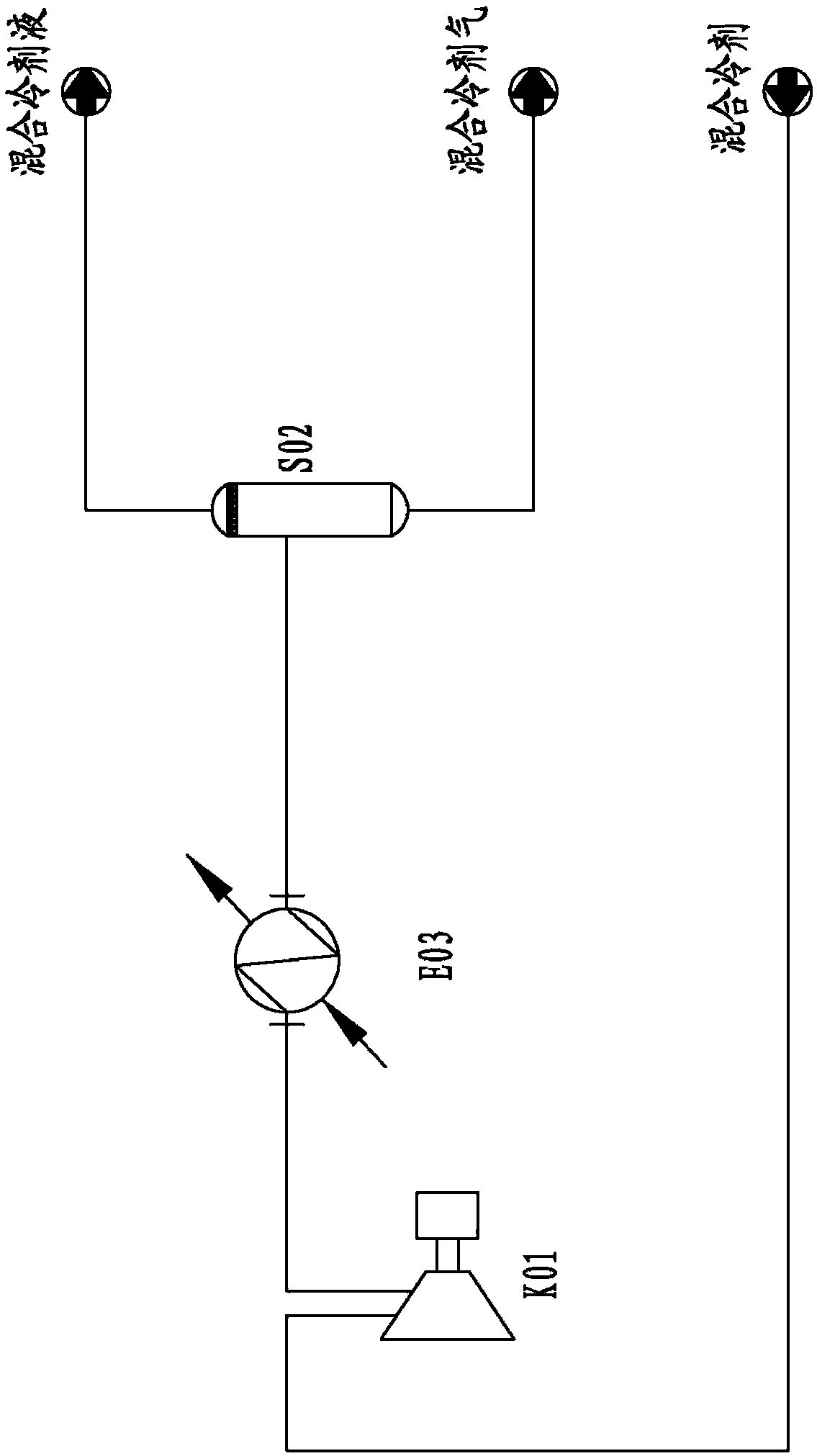

[0028] The isobutane dehydrogenation system of the present invention also includes a mixed refrigerant circulation refrigeration system for providing cooling capacity to the primary heat exchanger E01 and the secondary heat exchanger E02, and the mixed refrigerant circulation refrigeration system The refrigerant flow direction includes the mixed refrigerant compressor K01 for compressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com