High-performance silicon-carbon composite with core-shell structure, and preparation method and application of silicon-carbon composite in lithium ion battery

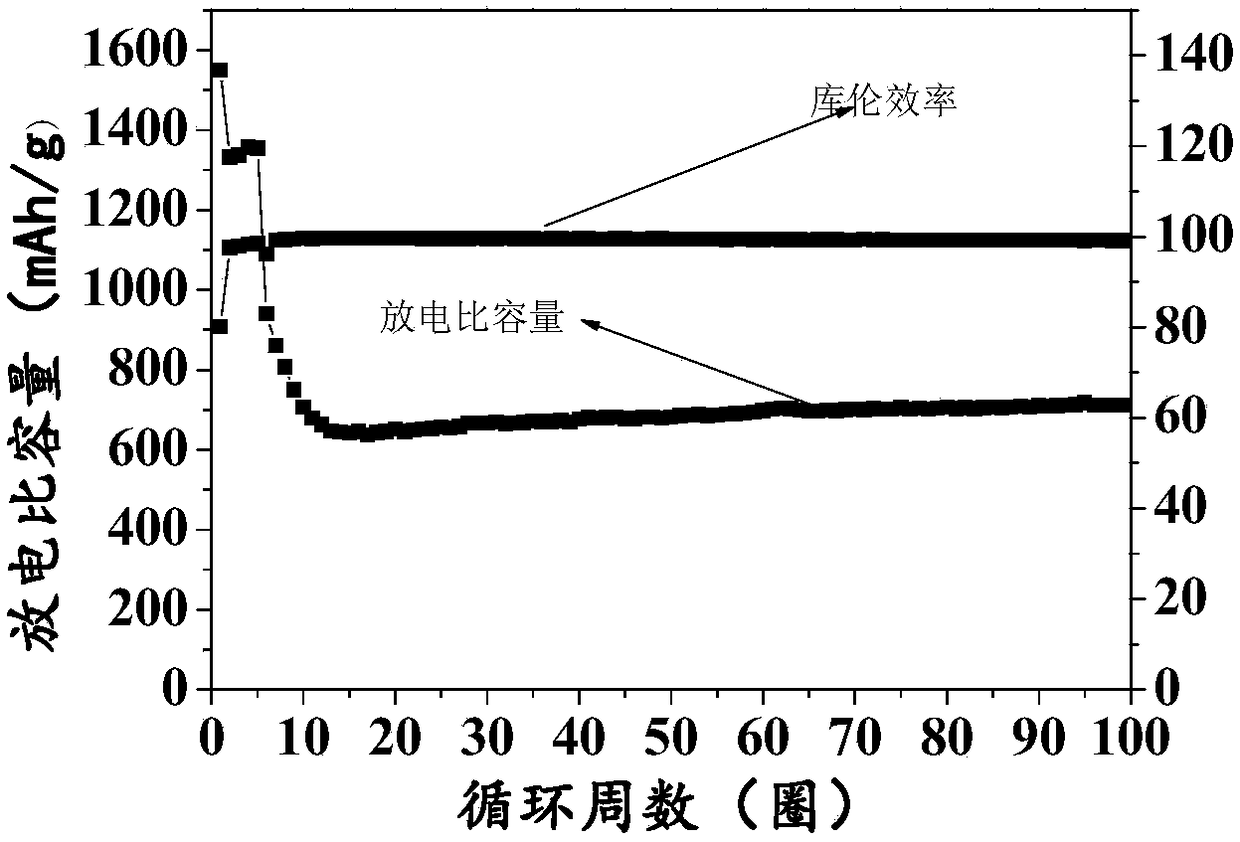

A technology of silicon-carbon composite materials and core-shell structure, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of inability to form a stable SEI film, capacity fading, and Coulombic efficiency reduction, and achieve excellent cycle stability and The effects of rate performance, boost performance, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Silicon powder treatment: Weigh 20g of 500 mesh commercial silicon powder, 200g of zirconium balls (grinding medium), put them into a ball mill pot, add a sealing ring, ball mill at 400rpm for 4 hours, and filter out the obtained micron silicon and zirconium balls through a sieve Zirconium balls are separated and processed to obtain micron silicon powder.

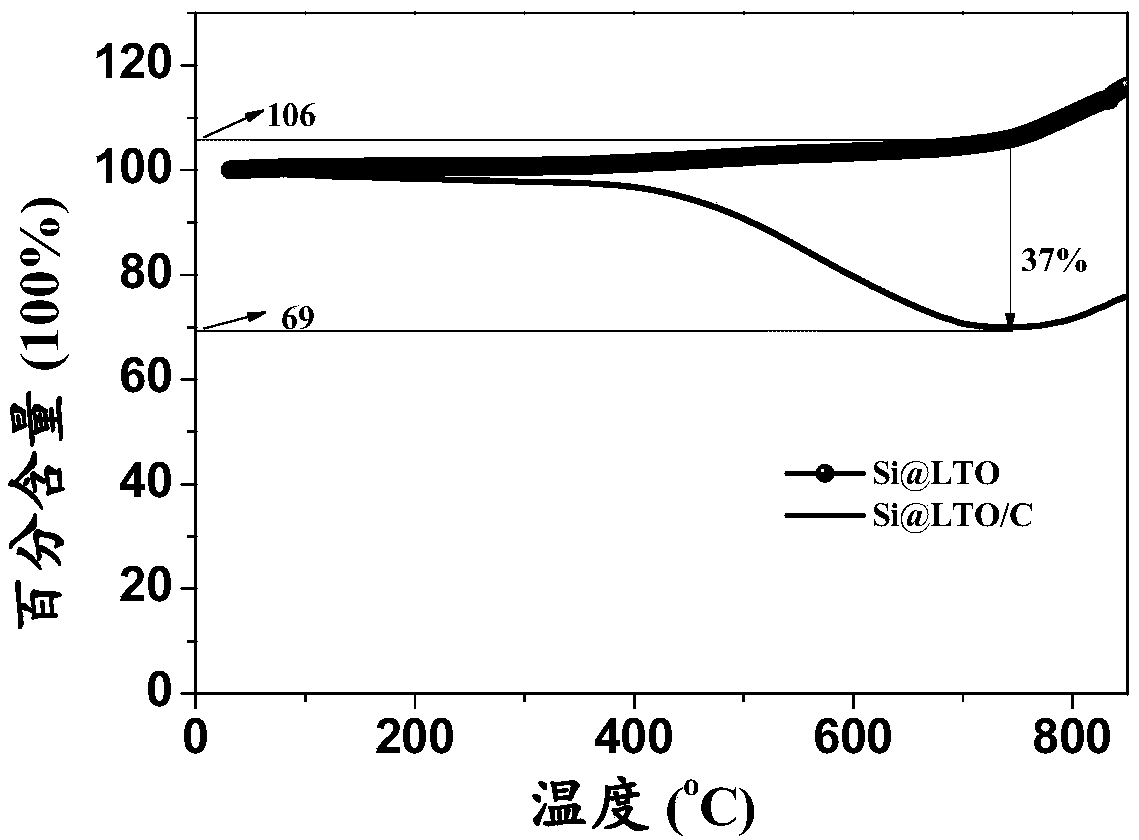

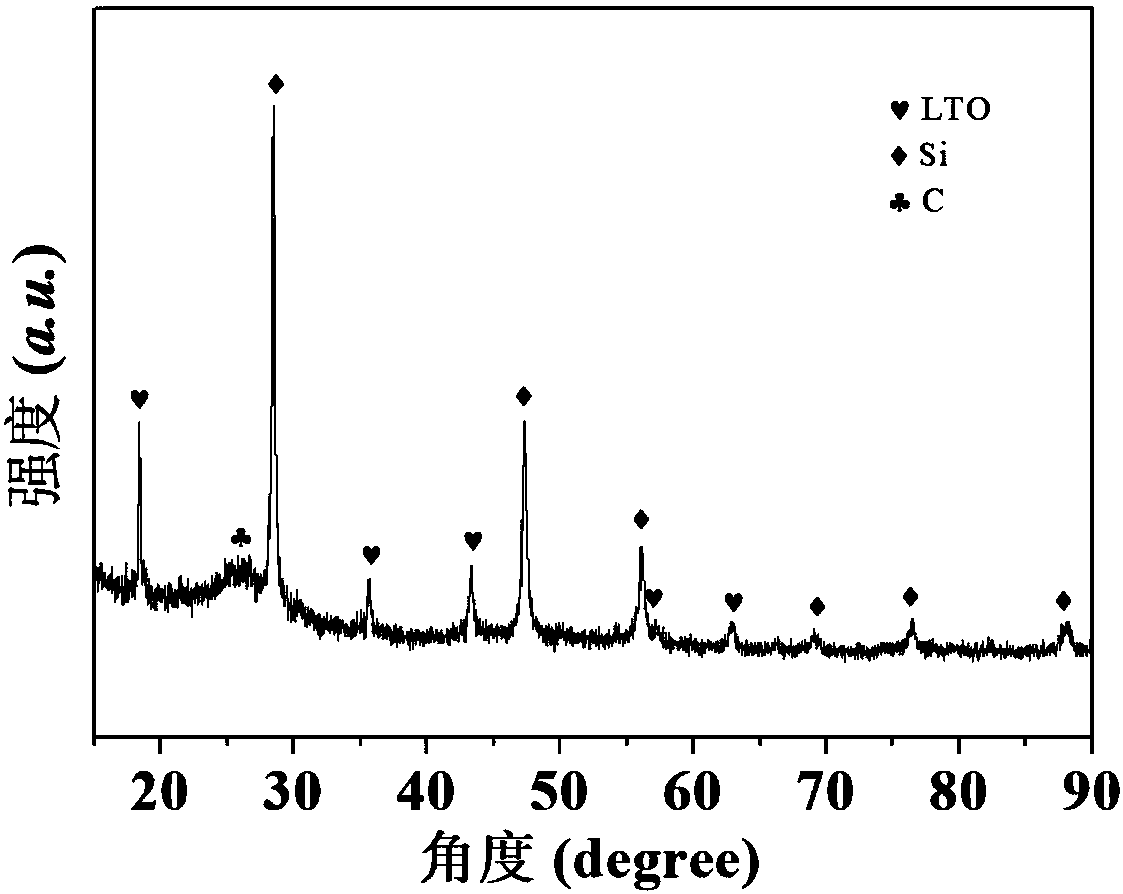

[0039]Two. the preparation of the high-performance silicon-carbon composite material with core-shell structure: take by weighing 7g micron silicon powder, 1g expanded graphite, 0.5g lithium titanate, 0.2g conductive carbon black, 1.3g carbon nanotube and 50g zirconium ball ( Grinding medium) was added into the ball mill jar, and a sealing ring was added, and ball milled at 500rpm for 48 hours, and the obtained sample was filtered through a sieve to remove zirconium balls to obtain a high-performance silicon-carbon composite material with a core-shell structure.

[0040] Take 0.16g of the high-performance silicon-c...

Embodiment 2

[0042] 1. Silicon powder treatment: Weigh 20g of 500 mesh commercial silicon powder, 200g of zirconium balls (grinding medium), put them into a ball mill pot, add a sealing ring, ball mill at 400rpm for 15h, and filter out the obtained micron silicon and zirconium balls through a sieve Zirconium balls are separated and processed to obtain micron silicon powder.

[0043] 2. Preparation of high-performance silicon-carbon composite material with core-shell structure: Weigh 6.31g of micron silicon powder, 1.75g of expanded graphite, 0.3g of lithium titanate, 0.1g of conductive carbon black, 1.54g of carbon nanotubes and 100g of zirconium Put the balls (milling medium) into the ball mill jar, add a sealing ring, and mill at 400rpm for 20h, filter the obtained samples through a sieve to remove the zirconium balls, and obtain a high-performance silicon-carbon composite material with a core-shell structure.

[0044] Take 0.16g of the high-performance silicon-carbon composite materia...

Embodiment 3

[0046] 1. Silicon powder treatment: Weigh 20g of 500 mesh commercial silicon powder, 200g of zirconium balls (grinding medium), put them into a ball mill pot, add a sealing ring, ball mill at 400rpm for 28 hours, and filter out the obtained micron silicon and zirconium balls through a sieve Zirconium balls are separated and processed to obtain micron silicon powder.

[0047] 2. Preparation of high-performance silicon-carbon composite material with core-shell structure: Weigh 5.54g of micron silicon powder, 3g of expanded graphite, 0.1g of lithium titanate, 0.06g of conductive carbon black, 1.3g of carbon nanotubes and 150g of zirconium balls (Grinding medium) was added into the ball mill jar, added with a sealing ring, ball milled at 800rpm for 40h, and the obtained sample was filtered through a sieve to remove zirconium balls to obtain a high-performance silicon-carbon composite material with a core-shell structure.

[0048] Take 0.16g of the high-performance silicon-carbon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com