Battery set core voltage sampling circuit

A technology of voltage sampling and battery packs, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of expensive chips, poor scalability, and high cost, and achieve enhanced anti-interference and safety, low cost, Effect of Preventing Leakage Current Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

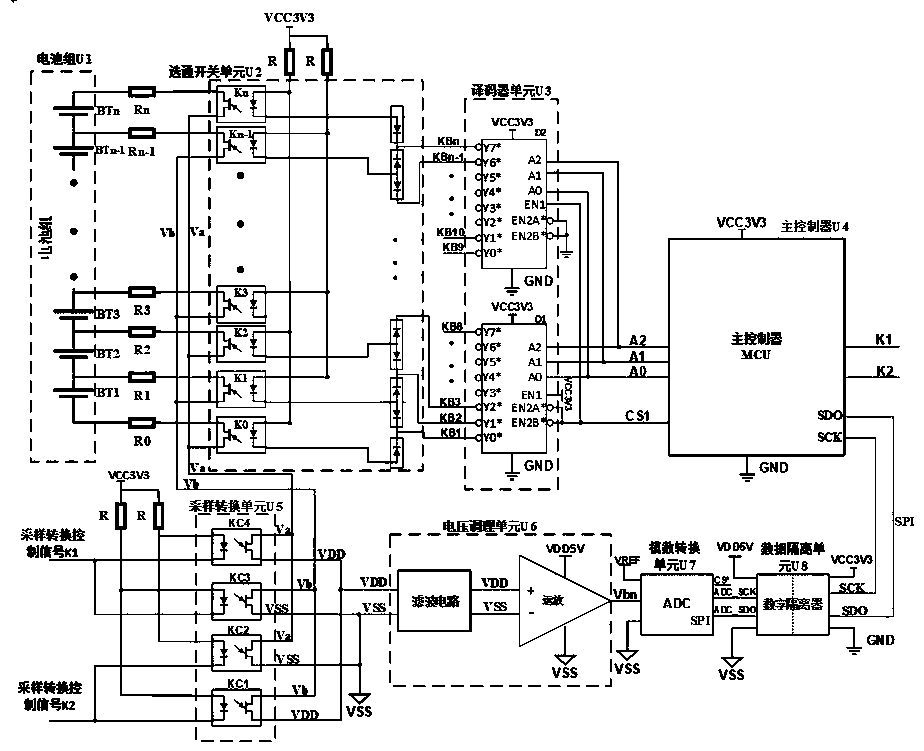

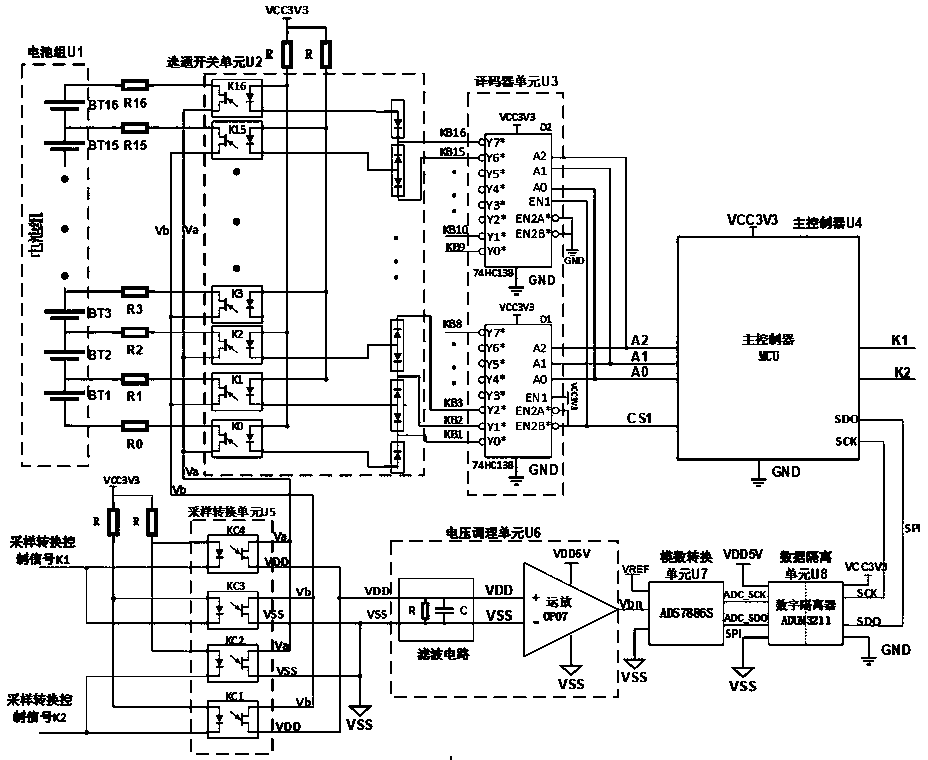

[0022] Example 1 as figure 2 shown. The battery pack U1 is composed of n single cells connected in series, including but not limited to lithium iron phosphate battery packs and ternary (NCM, NCA) lithium battery packs. The positive pole and negative pole of each battery cell in the battery pack U1 are connected to the collector (c pole) of the output terminal of the strobe switch through a series sampling resistor, and the positive and negative poles of n cells in the battery pack U1 are connected to the gate switch The n+1 isolation switches in unit U2 correspond to each other.

[0023] The gating switch unit U2 is composed of an isolating switch array of K0~Kn and a common anode diode array. The isolating switch includes but is not limited to optocoupler and optocoupler relay. The output collectors (c poles) of the isolation switch array K0~Kn are connected to the positive and negative poles of the cells in the battery pack U1 in one-to-one correspondence, and the output ...

Embodiment 2

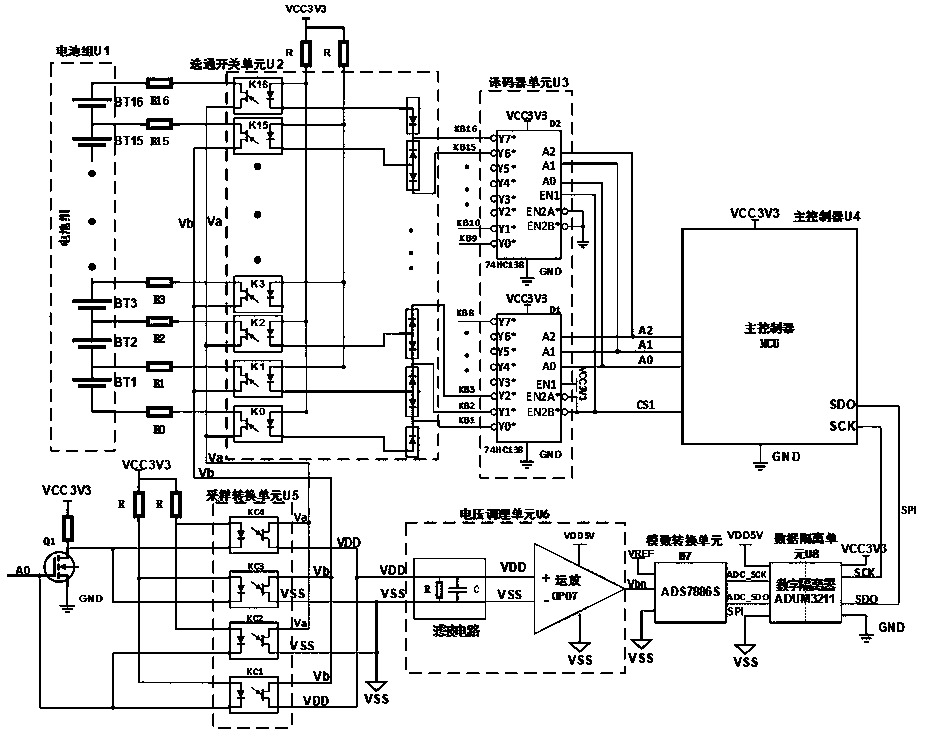

[0050] Example 2 as image 3 shown. According to the basic design idea of embodiment 1, the circuit can be changed into embodiment 2 with a little change.

[0051] The circuit formed by replacing the sampling conversion control signal K1K2 of the MCU with the gating control signal A0 in Embodiment 2 can also realize the gating control of the sampling conversion unit U5. The corresponding changes in the working principle of Embodiment 2 are: when A=0 (sampling of odd-numbered cells), MOS transistor Q1 is turned off, KC1 and KC2 in the sampling conversion unit U5 are turned on, KC3 and KC4 are turned off, and K1K2=10 is realized The effect is the same; when A=1 (even cell sampling), MOS transistor Q1 is turned on, KC1 and KC2 in the sampling conversion unit U5 are turned off, KC3 and KC4 are turned on, and the effect is the same as K1K2=01. The working principle of other parts of Embodiment 2 is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com