Cadmium telluride glass and crystal silicon wafer photovoltaic cell composite assembly and preparation method thereof

A technology of photovoltaic cells and composite components, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as high cost and low photoelectric conversion efficiency, achieve extended service life, conform to products and production processes, and increase the discharge of "three wastes" Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

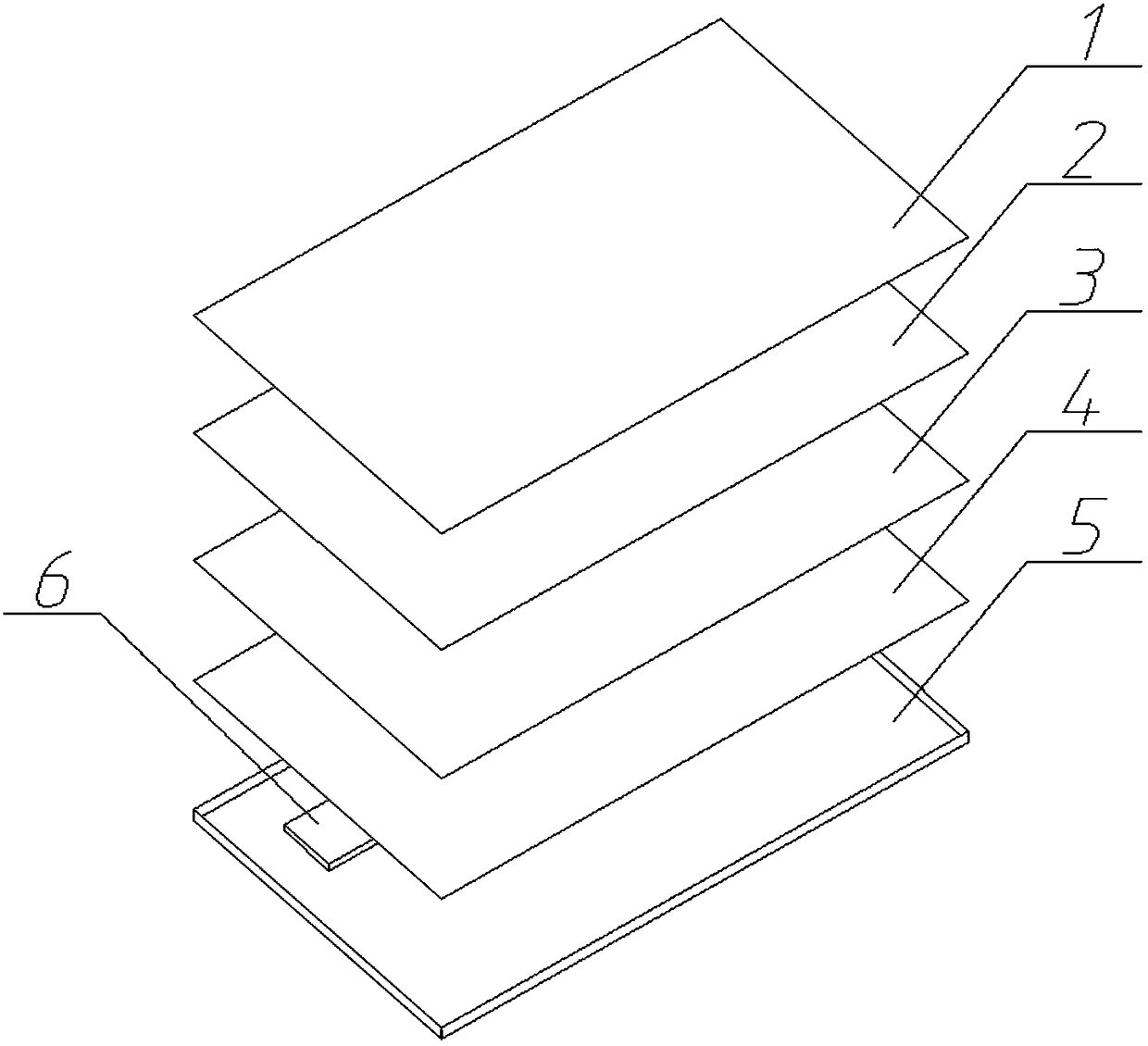

[0063] The following is attached Figure 1~2 The present invention is described in further detail. A kind of cadmium telluride glass photovoltaic cell and crystalline silicon wafer photovoltaic cell composite assembly that the present invention proposes, the specific technical scheme that takes is:

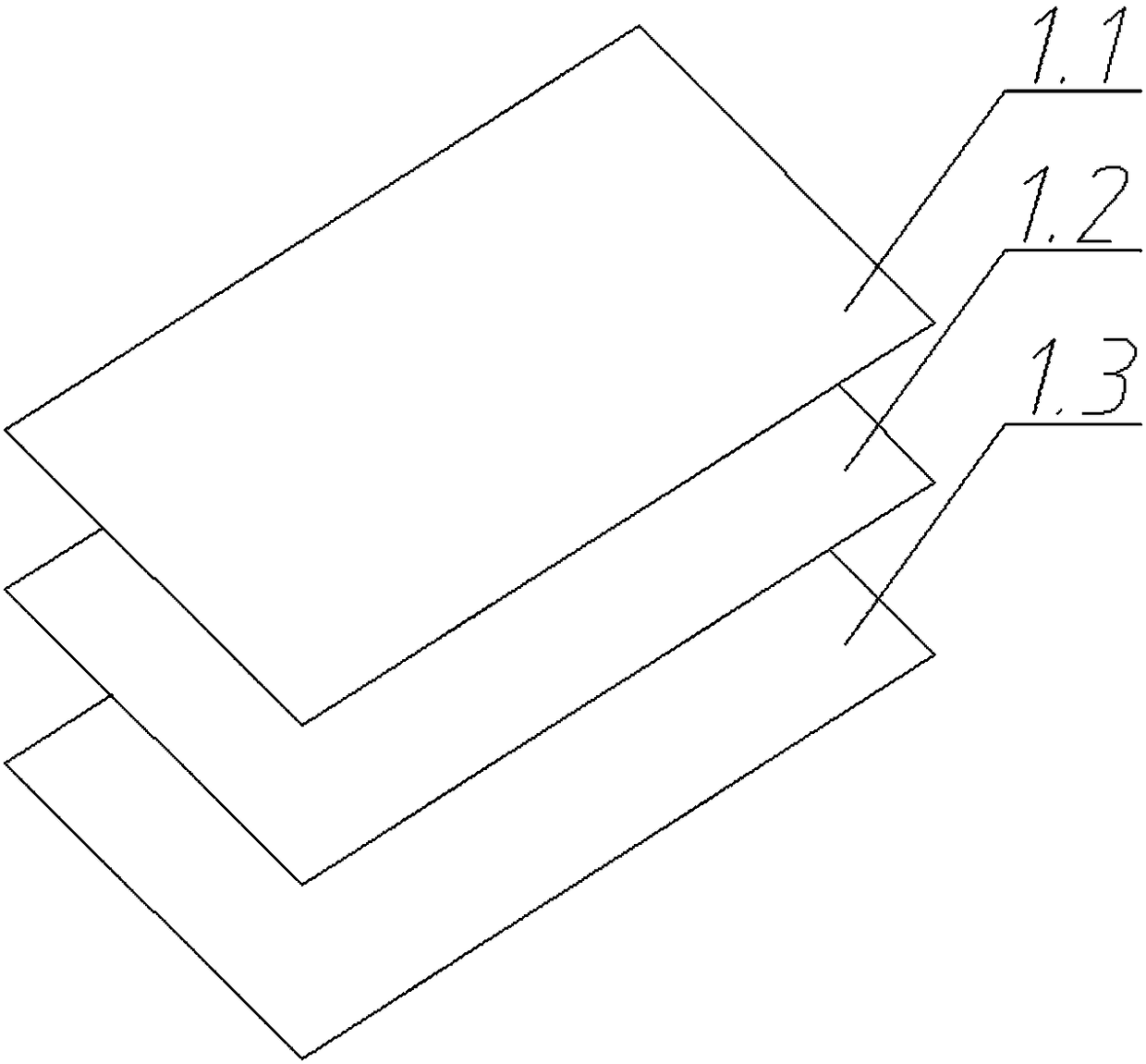

[0064] A composite assembly of cadmium telluride glass photovoltaic cell and crystalline silicon wafer photovoltaic cell, which sequentially includes: cadmium telluride glass 1, crystalline silicon wafer 2, EVA packaging film 3, TPT back plate 4, aluminum alloy frame 5 and junction box 6 , the above-mentioned cadmium telluride glass 1, crystal silicon wafer 2, EVA packaging film 3 and TPT backplane 4 are sequentially laid and laminated in layers, and fixed by the above-mentioned aluminum alloy frame 5, and the above-mentioned junction box 6 is fixed on the TPT backplane with silica gel 4 surfaces; the cadmium telluride glass comprises in turn: tempered glass 1.1, a polyurethane f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com