Roller bed type tablecloth disinfecting device and disinfecting process thereof

A sterilizing device and roller-type technology, which can be used in disinfection, manufacturing tools, metal processing equipment, etc., can solve problems such as bacterial residues on the surface of tablecloths and potential safety hazards, and achieve improved sterilization effects, strong pertinence, and low bacterial residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

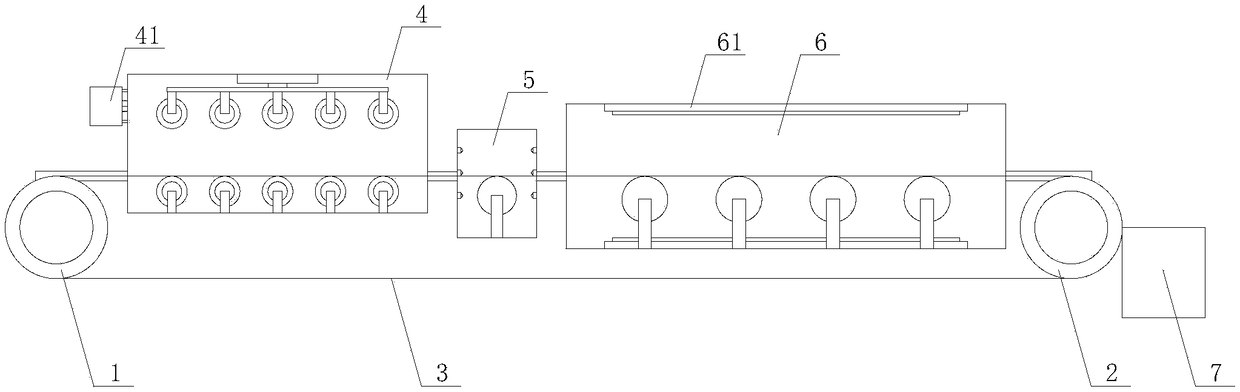

[0028] from figure 1 It can be seen that a roller-type tablecloth disinfection device in this embodiment includes a driving roller 1 and a driven roller 2, the outer rings of the driving roller 1 and the driven roller 2 are equipped with a conveyor belt 3, and the driving roller 1 and the driven roller An ozone sterilizing box 4 , a preheating drying box 5 and an ultraviolet disinfection box 6 are sequentially arranged between the moving rollers 2 , and a finished product recycling box 7 is arranged on the side of the driven roller 2 .

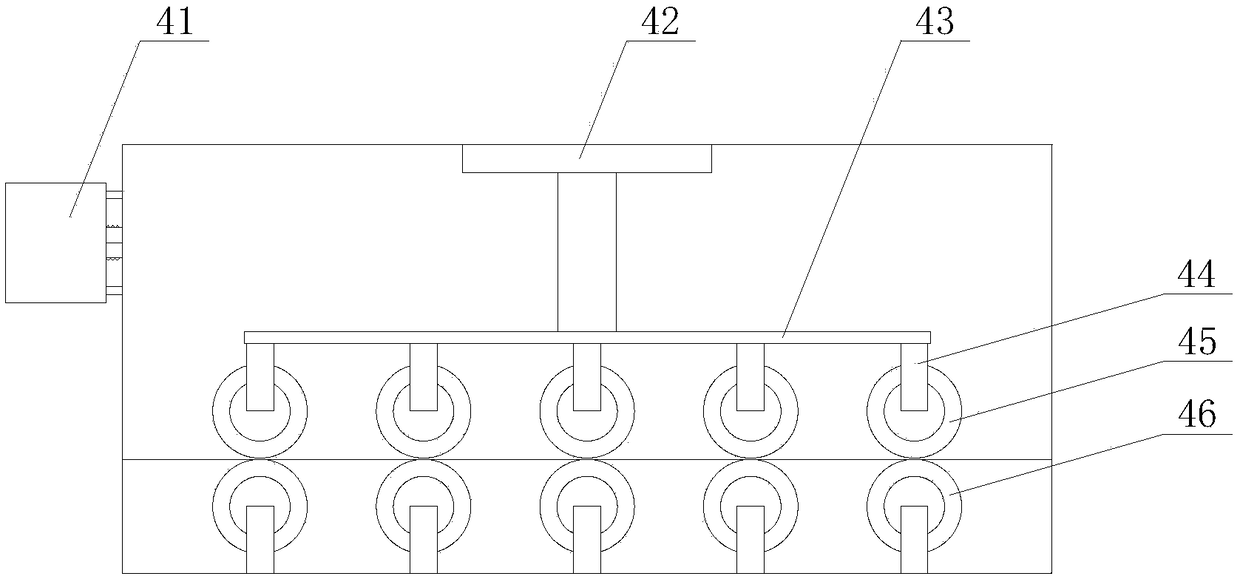

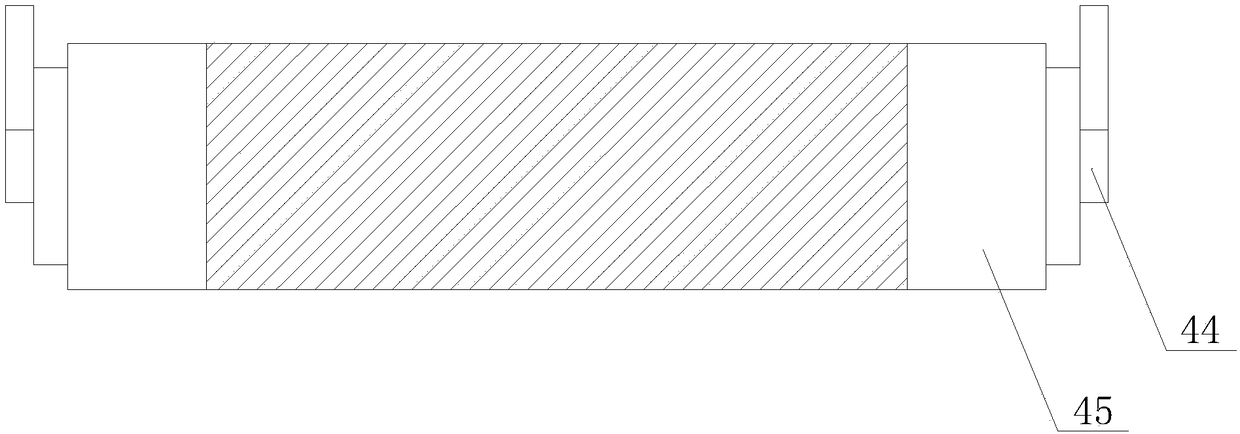

[0029] from figure 2 It can be seen that an ozone generator 41 is fixedly installed on the side of the ozone sterilization cabinet 4, and the output end of the ozone generator 41 is communicated with the ozone sterilization cabinet 4 through a pipeline, and the ozone generator 41 is connected to the ozone sterilization cabinet 4. Ozone is transported inside so as to achieve the effect of ozone sterilization. A hydraulic lift cylinder 42 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com