Lignin quaternary ammonium salt cation asphalt emulsifier and preparation method thereof

A technology of asphalt emulsifier and lignin, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of high cost, cumbersome preparation steps, high temperature reaction, etc., and achieve excellent performance, good storage stability, emulsification Fine and uniform asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Example 1 Lignin Quaternary Ammonium Salt Cationic Asphalt Emulsifier

[0030] Follow the steps below:

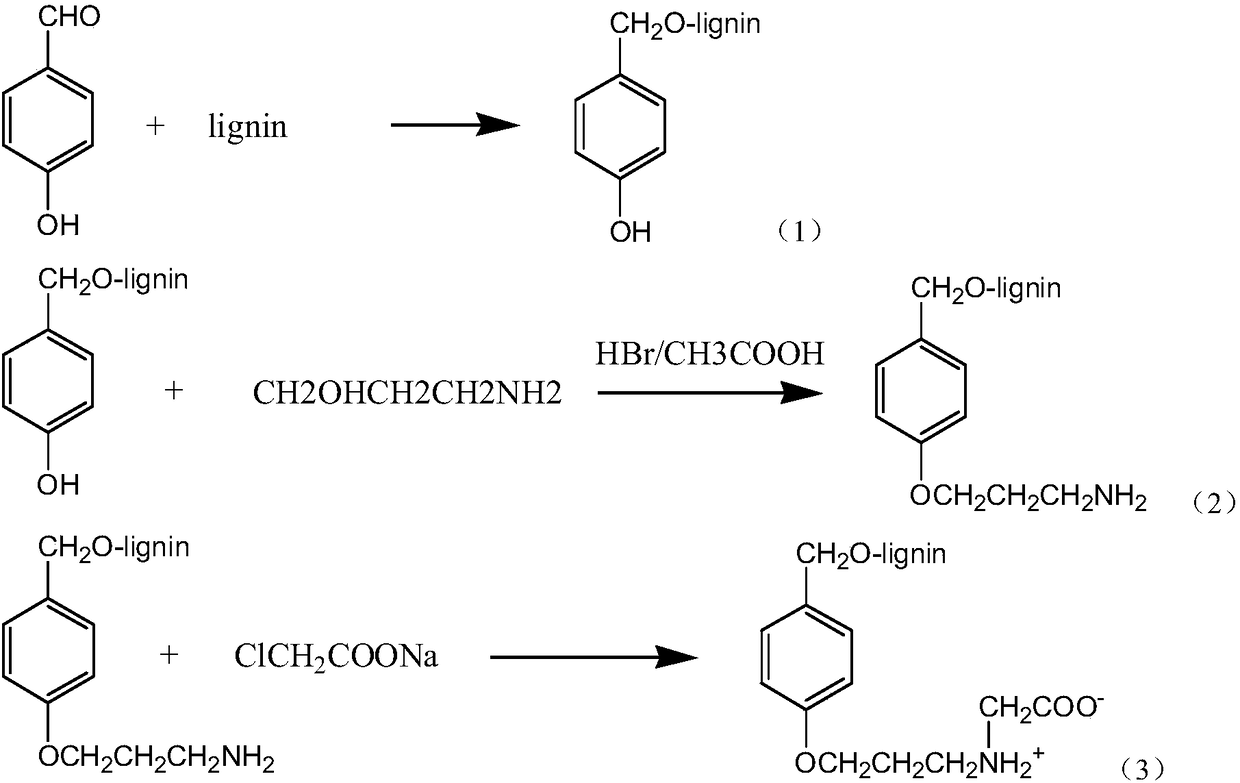

[0031] (1) Add 1 mol of p-hydroxybenzaldehyde into the reaction flask, sequentially add 1 mol of thionyl chloride and 2 mol of triethylamine, react at room temperature for 2-3 hours, add 1 mol of lignin, stir and react at room temperature for 2 hours, and obtain intermediate I;

[0032] (2) Dissolve intermediate I in glacial acetic acid, add 1 mol of 30% hydrobromic acid dropwise, react at 40-45°C for 2 hours, continue to add 1 mol of 3-amino-1-propanol, react at room temperature for 3 hours, intermediate II;

[0033] (3) Dissolve the intermediate II in dichloromethane, slowly add 1 mol of sodium chloroacetate dropwise at 0°C, and react for 2 hours to obtain a lignin-based cationic asphalt emulsifier with a yield of 67%.

[0034] The prepared lignin-based quaternary ammonium salt cationic asphalt emulsifier was separated and purified for FTIR detectio...

Embodiment 2

[0037] The preparation of embodiment 2 lignin quaternary ammonium salt cationic asphalt emulsifier

[0038] Follow the steps below:

[0039] (1) Add 1 mol of p-hydroxybenzaldehyde into the reaction flask, add 2 mol of thionyl chloride and 8 mol of triethylamine in turn, react at room temperature for 2-3 hours, add 1.5 mol of lignin, stir and react at room temperature for 2 hours, and obtain intermediate I;

[0040] (2) Dissolve intermediate I in glacial acetic acid, add 2 mol of 30% hydrobromic acid dropwise, react at 40-45°C for 2 hours, continue to add 3 mol of 3-amino-1-propanol, react at room temperature for 3 hours, intermediate II;

[0041] (3) Dissolve the intermediate II in dichloromethane, slowly add 3 mol of sodium chloroacetate dropwise at 0°C, and react for 2 hours to obtain a lignin-based cationic asphalt emulsifier with a yield of 70%.

[0042] The prepared lignin-based quaternary ammonium salt cationic asphalt emulsifier was separated and purified for FTIR dete...

Embodiment 3

[0043] Preparation of Example 3 Lignin Quaternary Ammonium Salt Cationic Asphalt Emulsifier

[0044] Follow the steps below:

[0045] (1) Add 1 mol of p-hydroxybenzaldehyde into the reaction flask, add 1.5 mol of thionyl chloride and 5 mol of triethylamine in turn, react at room temperature for 2-3 hours, add 1.3 mol of lignin, stir and react at room temperature for 2 hours, and obtain intermediate I;

[0046](2) Dissolve intermediate I in glacial acetic acid, add 1.5mol 30% hydrobromic acid dropwise, react at 40-45°C for 2h, continue to add 2mol 3-amino-1-propanol, react at room temperature for 3h, intermediate II;

[0047] (3) Dissolve the intermediate II in dichloromethane, slowly add 2 mol of sodium chloroacetate dropwise at 0°C, and react for 2 hours to obtain a lignin-based cationic asphalt emulsifier with a yield of 82%.

[0048] The prepared lignin-based quaternary ammonium salt cationic asphalt emulsifier was separated and purified for FTIR detection, and the results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com