Fluorinated tin-based glass frit and method for manufacturing same

A tin fluoride-based, manufacturing method technology, applied in the field of tin fluoride-based glass frit, can solve the problems of reduced ratio, reduced water resistance, reduced transparency, coloring, etc., and achieves excellent sealing processability, excellent water resistance, and reliable The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1~21

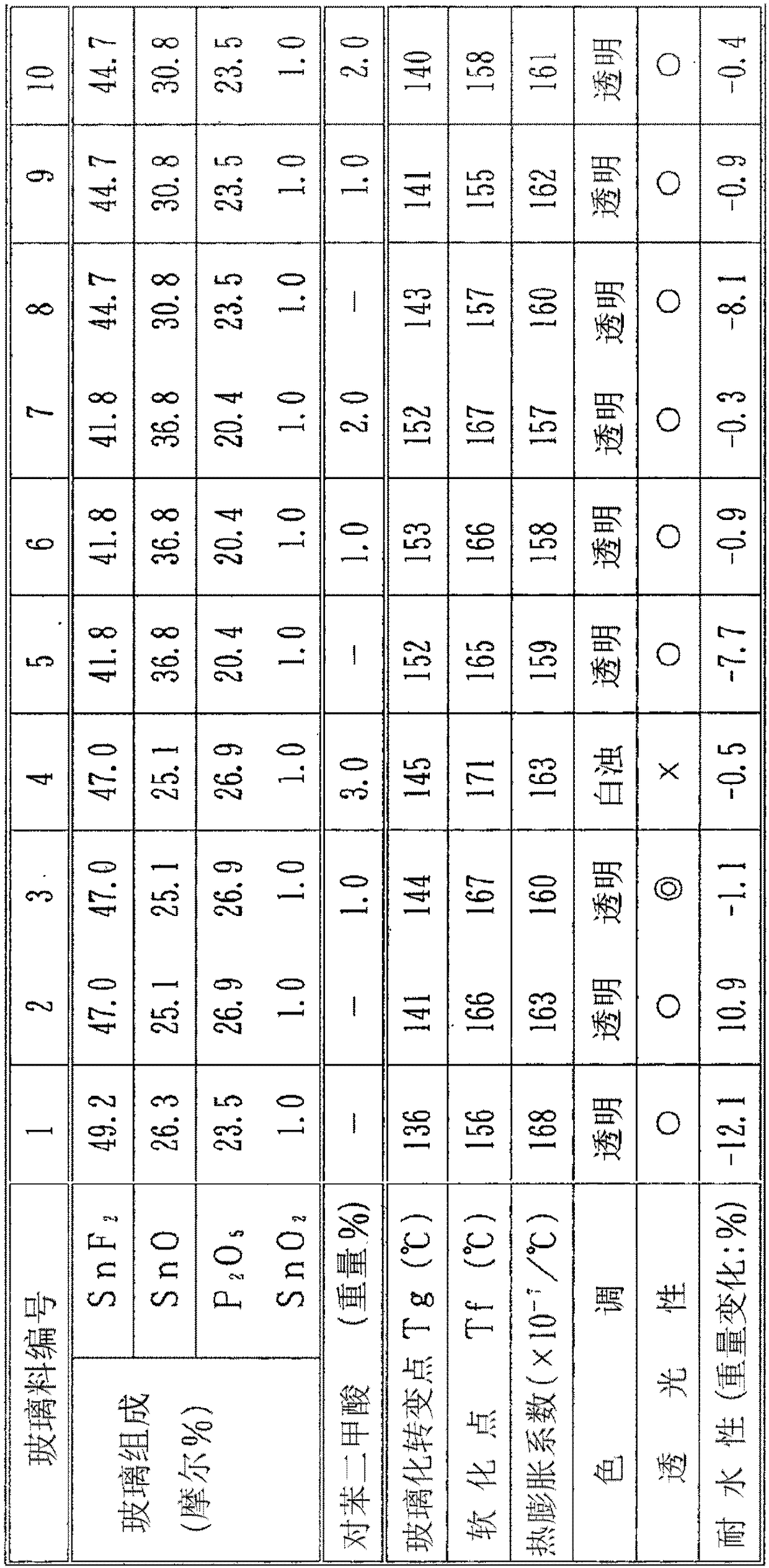

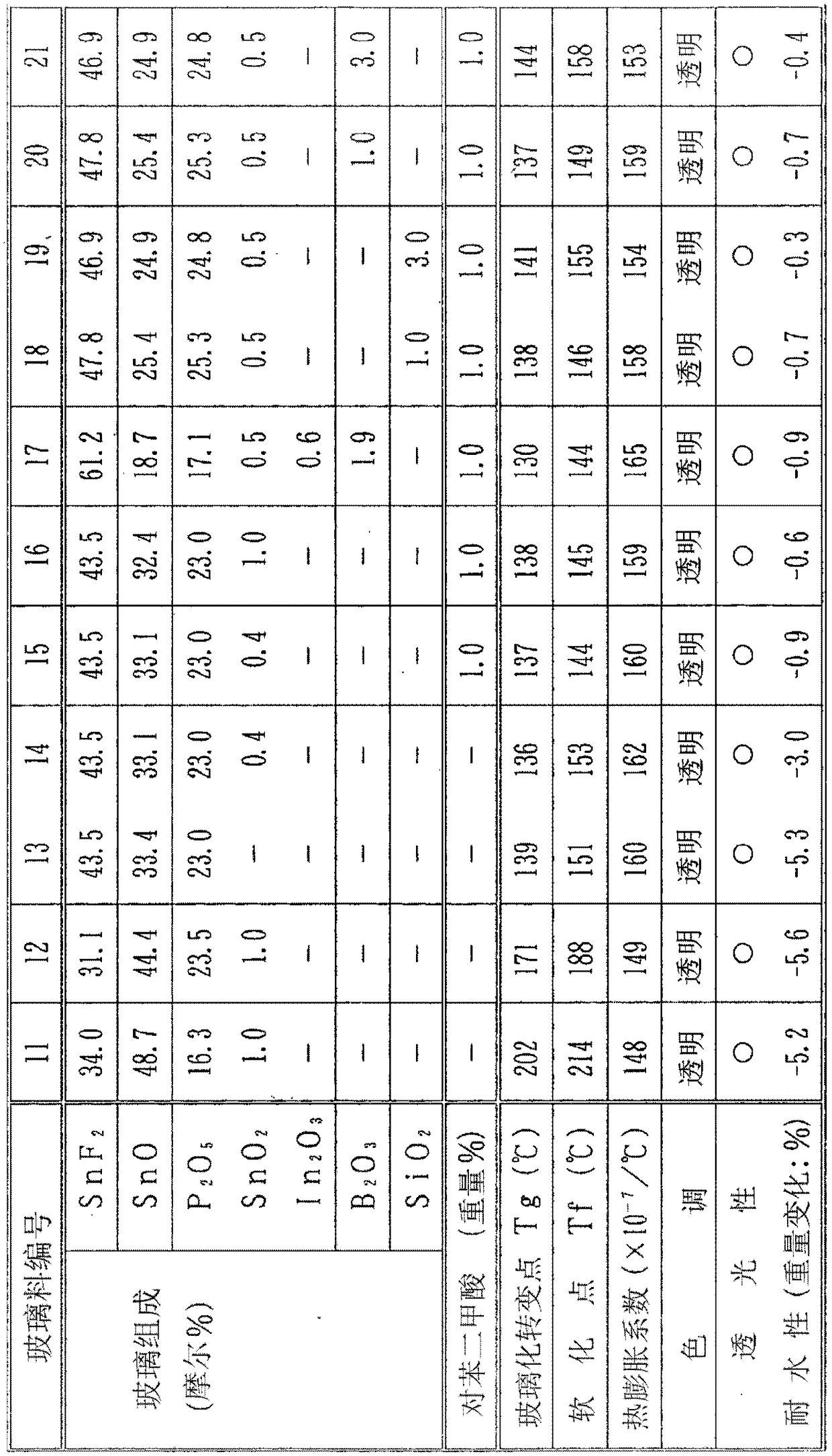

[0054] will be made from SnF that will be used as a glass raw material 2 , SnO, P 2 o 5 (using ammonium hydrogen phosphate), SnO 2 、In 2 o 3 , B 2 o 3 , SiO 2The powders are mixed at the ratios (mol %) described in Tables 1 and 2 described later, and are added and mixed at the ratios (weight %) described in Tables 1 and 2 to these glass raw material powders as aromatic 10 g of terephthalic acid powders of carboxylic acids were stored in an alumina crucible with a capacity of 50 cc, heated in a muffle furnace at 380°C to 500°C for 40 minutes to melt, and then The melt is flowed into an alumina boat and recovered, and a glass bar with a length of 4 mm in length and width and a length of 11 mm is cut out from the cooled glass bar, and a particle size of 100 μm is produced from the remaining part by crushing and classifying in an automatic mortar frit below.

[0055] Glass transition point [Tg], softening point [Tf], coefficient of thermal expansion [CTE], color tone, tra...

manufacture example 22~32

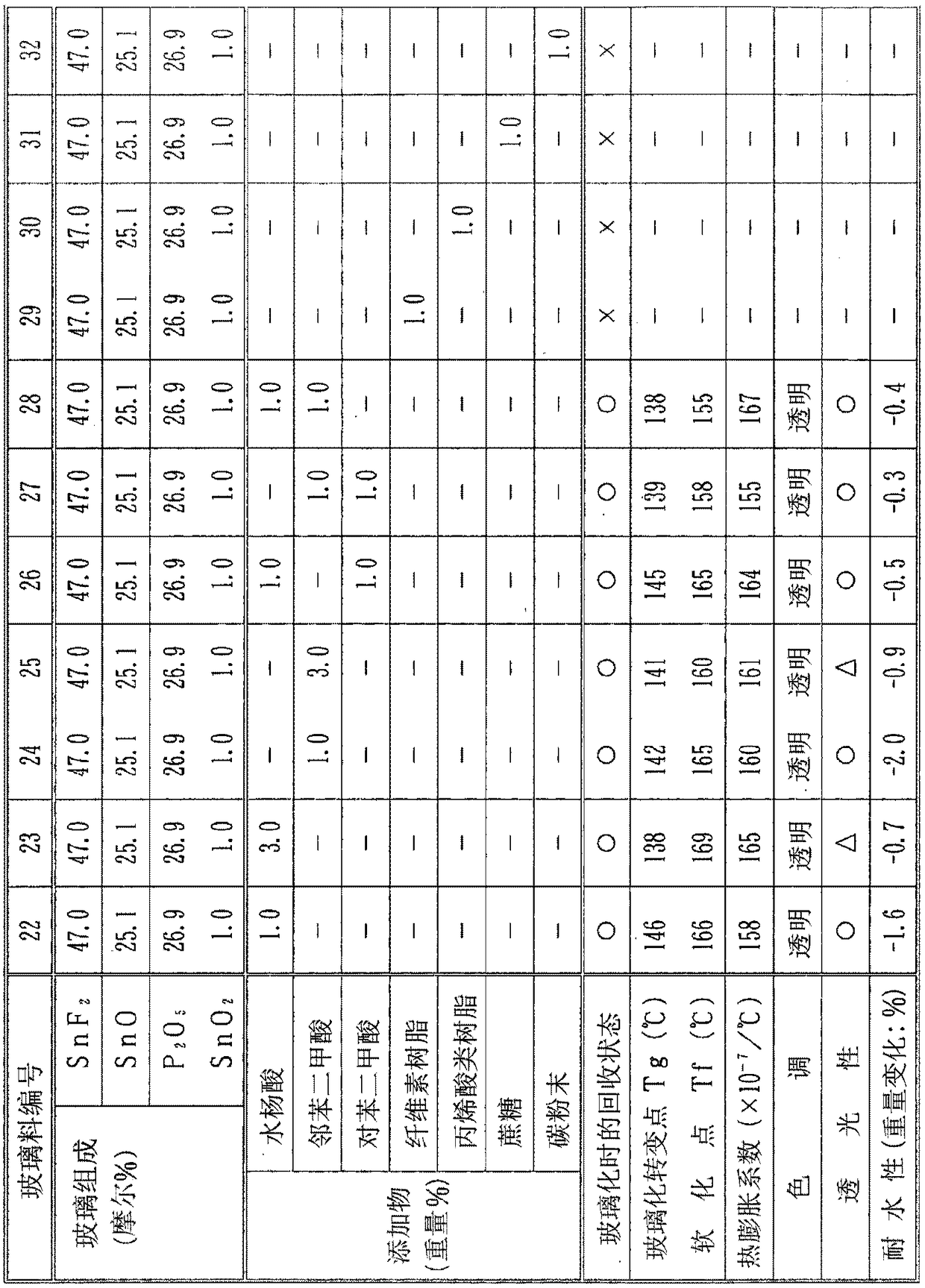

[0078] To the glass raw material powder of Production Example 2 above, each additive described in Table 3 except terephthalic acid was added and mixed at the ratio (weight %) described in Table 3 described below. 10 g of the above-mentioned production examples 1 to 21 were carried out in the same manner as above-mentioned production examples 1 to 21, which were heated and melted and recovered, and the above-mentioned same glass rod and glass frit were produced from the cooled glass rod. Then, using each of the above-mentioned glass frits and glass rods, the glass transition point [Tg], softening point [Tf], thermal expansion coefficient [CTE], color tone, light transmittance, and water resistance were evaluated in the same manner as in Production Examples 1 to 21. research. The results are shown in Table 3 below. In Manufacture Examples 29 to 32, since the collected glass rods contained carbides and became cloudy, they were judged to be poor in quality, and the measurement of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com