Non-aqueous lithium storage element

A technology for electric storage components and non-aqueous electrolytes, which is applied to lithium batteries, electrical components, non-aqueous electrolyte batteries, etc., and can solve problems such as the suppression of internal short-circuit thermal runaway without consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

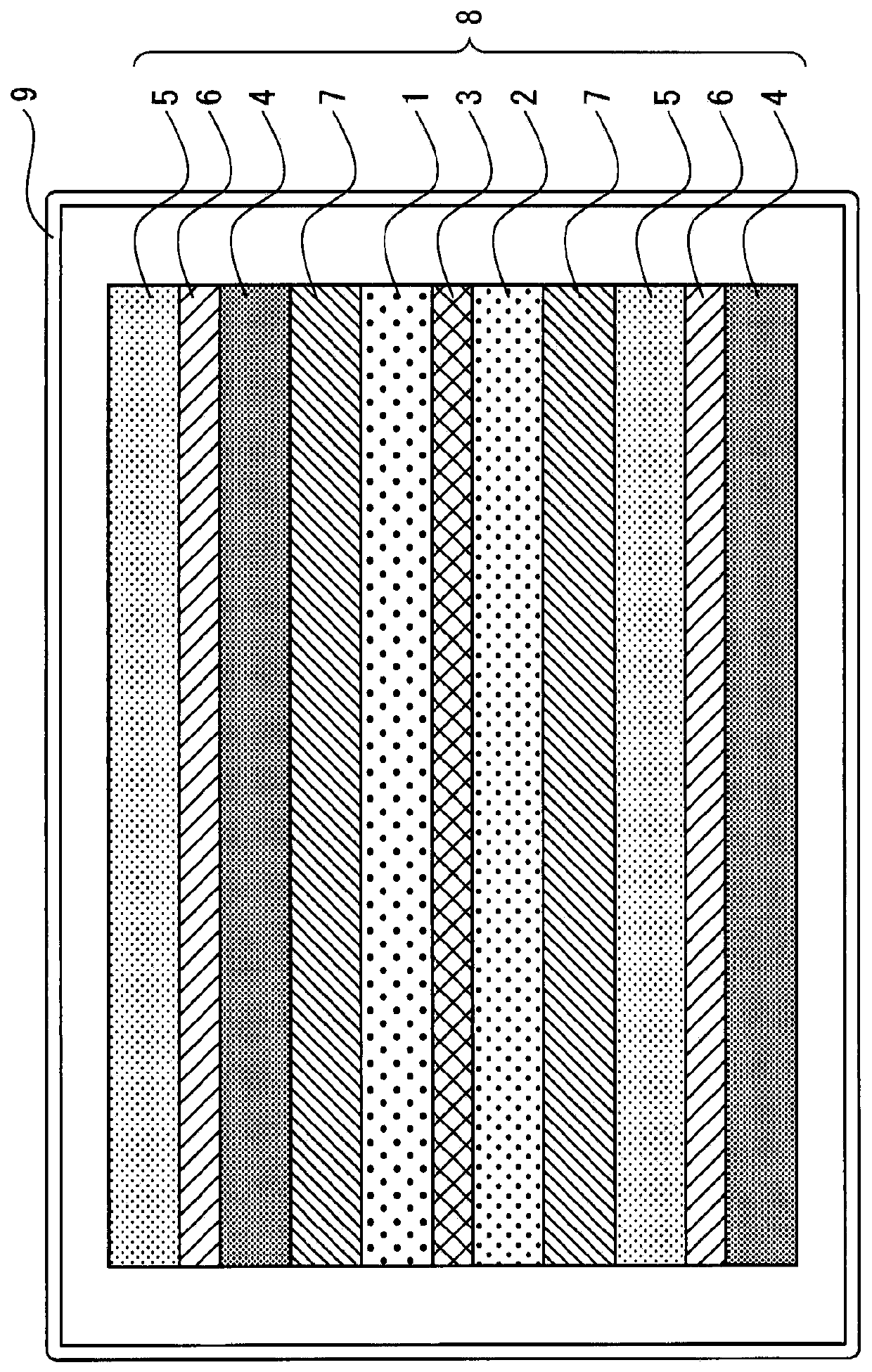

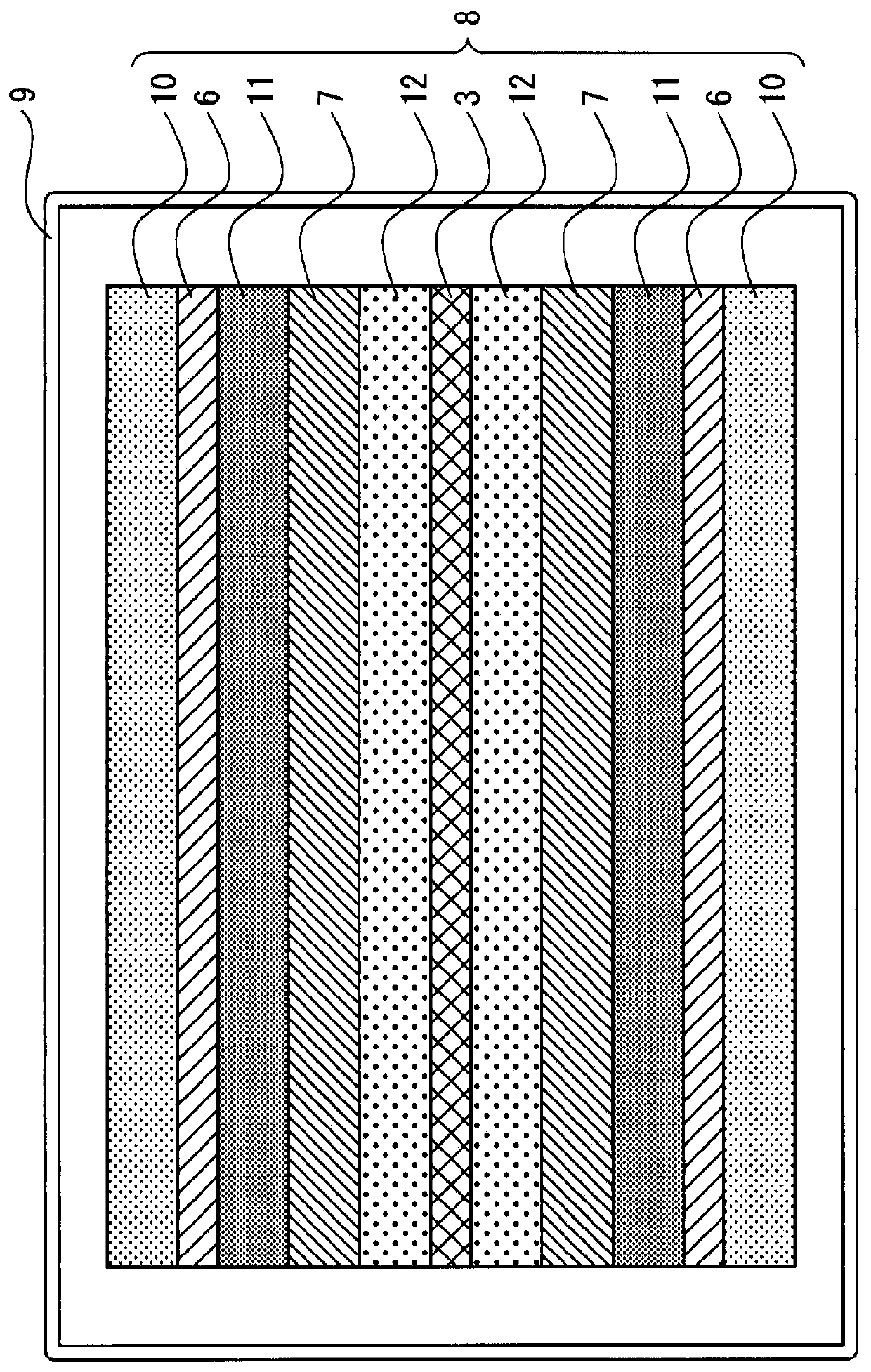

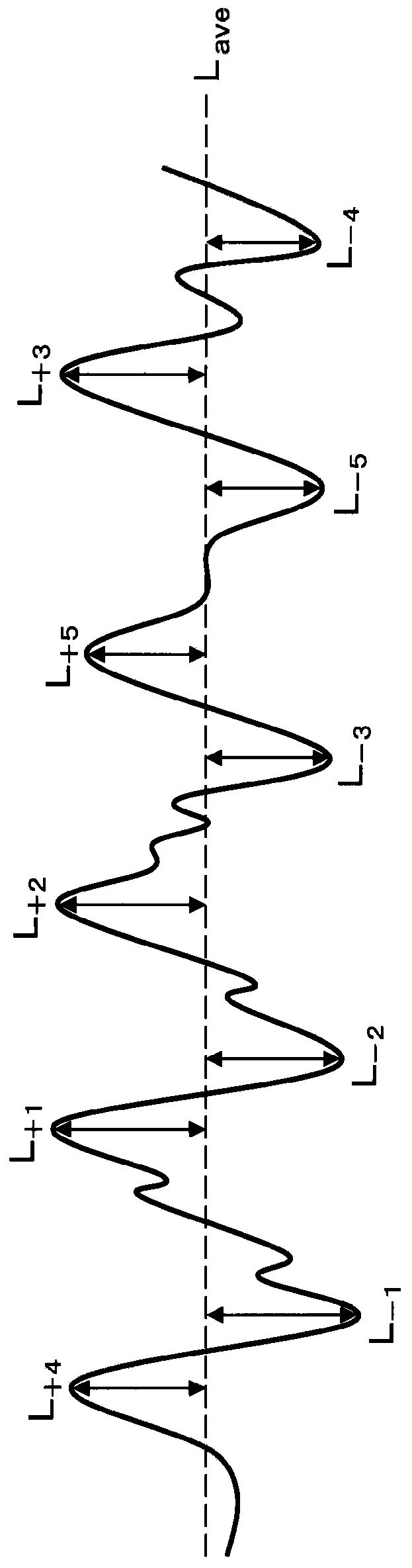

Method used

Image

Examples

preparation example Construction

[0303] Regarding the preparation of the coating liquid, a part or all of various material powders containing the negative electrode active material may be dry-blended, followed by adding water or an organic solvent, and / or dissolving or dispersing a binder or a dispersion stabilizer in them. A liquid or slurry-like substance is used to prepare a coating solution. Alternatively, a binder or a dispersion stabilizer may be dissolved or dispersed in water or an organic solvent, and various material powders including a negative electrode active material may be added to the obtained liquid or slurry to prepare a coating liquid.

[0304] The method of dissolution or dispersion is not particularly limited, and dispersing machines such as a homodisperser, a multi-shaft disperser, a planetary mixer, and a thin-film rotary high-speed mixer, etc., can be suitably used. In order to obtain a coating liquid in a good dispersion state, it is preferable to disperse at a peripheral speed of 1 m...

Embodiment 1

[0559]

preparation example 1a

[0561] Put the crushed coconut shell carbides into a small carbonization furnace, and carry out carbonization treatment at 500°C for 3 hours under nitrogen atmosphere to obtain carbides. Put the obtained carbide into the activation furnace, introduce the water vapor obtained by heating with the preheating furnace into the activation furnace at 1 kg / h, and raise the temperature to 900°C for 8 hours for activation. The activated carbide was taken out and cooled under a nitrogen atmosphere to obtain activated activated carbon. The obtained activated carbon was washed with water for 10 hours to remove water, dried in an electric dryer kept at 115° C. for 10 hours, and pulverized with a ball mill for 1 hour to obtain activated carbon 1 .

[0562] The average particle diameter of the activated carbon 1 was measured using a laser diffraction particle size distribution analyzer (SALD-2000J) manufactured by Shimadzu Corporation, and it was 4.2 μm. Moreover, the pore distribution of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com