Collagen coating on porous titanium surface and preparation method thereof

A technology of collagen and porous titanium, applied in coatings, pharmaceutical formulations, prostheses, etc., can solve the problems of long time for new bone formation on the surface and unfavorable biological stability of implants, so as to improve biocompatibility and Tissue repair ability, high spraying efficiency, simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] As an embodiment of the preparation method of the collagen coating on the porous titanium surface of the present invention, the preparation method of the collagen coating on the porous titanium surface described in this embodiment comprises the following steps:

[0027] (1) Sample pretreatment: Use acetone, ethanol, and pure water to ultrasonically clean the micro-arc oxidation porous titanium alloy in sequence. Each reagent is washed 3 times for 10 minutes each time, and dried in a vacuum oven after cleaning.

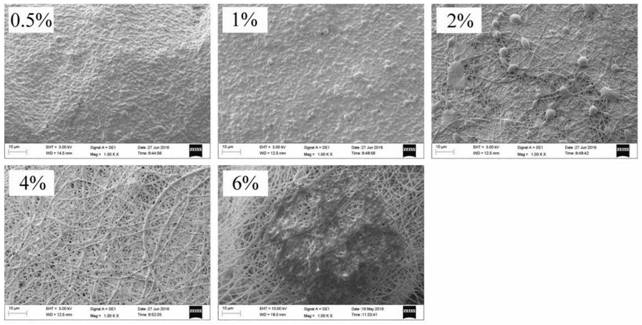

[0028] (2) Collagen solution preparation: Hexafluoroisopropanol was used as a solvent to prepare a collagen solution, the mass fraction of collagen in the collagen solution was 0.5%, the collagen molecular weight was 360 kDa, and magnetic stirring was carried out at room temperature for 3 hours.

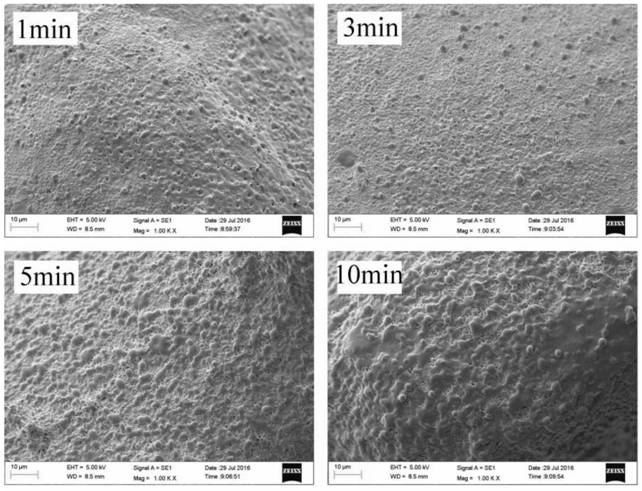

[0029] (3) Electrostatic spraying: transfer the dissolved collagen solution to a 20mL syringe, replace the electrospinning needle, and fix it on the injector. Adjust t...

Embodiment 2

[0031] As an embodiment of the preparation method of the collagen coating on the porous titanium surface of the present invention, the preparation method of the collagen coating on the porous titanium surface described in this embodiment comprises the following steps:

[0032] (1) Sample pretreatment: Use acetone, ethanol, and pure water to ultrasonically clean the micro-arc oxidation porous titanium alloy in sequence. Each reagent is washed 3 times for 10 minutes each time, and dried in a vacuum oven after cleaning.

[0033] (2) Collagen solution preparation: Hexafluoroisopropanol was used as a solvent to prepare a collagen solution, the mass fraction of collagen in the collagen solution was 1%, the molecular weight of collagen was 270 kDa, and magnetic stirring was carried out at room temperature for 3 hours.

[0034] (3) Electrostatic spraying: transfer the dissolved collagen solution to a 20mL syringe, replace the electrospinning needle, and fix it on the injector. Adjust ...

Embodiment 3

[0036] As an embodiment of the preparation method of the collagen coating on the porous titanium surface of the present invention, the preparation method of the collagen coating on the porous titanium surface described in this embodiment comprises the following steps:

[0037] (1) Sample pretreatment: Use acetone, ethanol, and pure water to ultrasonically clean the micro-arc oxidation porous titanium alloy in sequence. Each reagent is washed 3 times for 10 minutes each time, and dried in a vacuum oven after cleaning.

[0038] (2) Collagen solution preparation: Hexafluoroisopropanol was used as a solvent to prepare a collagen solution, the mass fraction of collagen in the collagen solution was 2%, the molecular weight of collagen was 300 kDa, and magnetic stirring was carried out at room temperature for 3 hours. (3) Electrostatic spraying: transfer the dissolved collagen solution to a 20mL syringe, replace the electrospinning needle, and fix it on the injector. Adjust the volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com