Filtering equipment for strong-acid and strong-alkali waste gas

A filtration equipment, strong acid and strong alkali technology, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low removal efficiency, loss, easy waste of neutralizing reagents, etc., to improve filtration efficiency and save money. The effect of reagent use and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

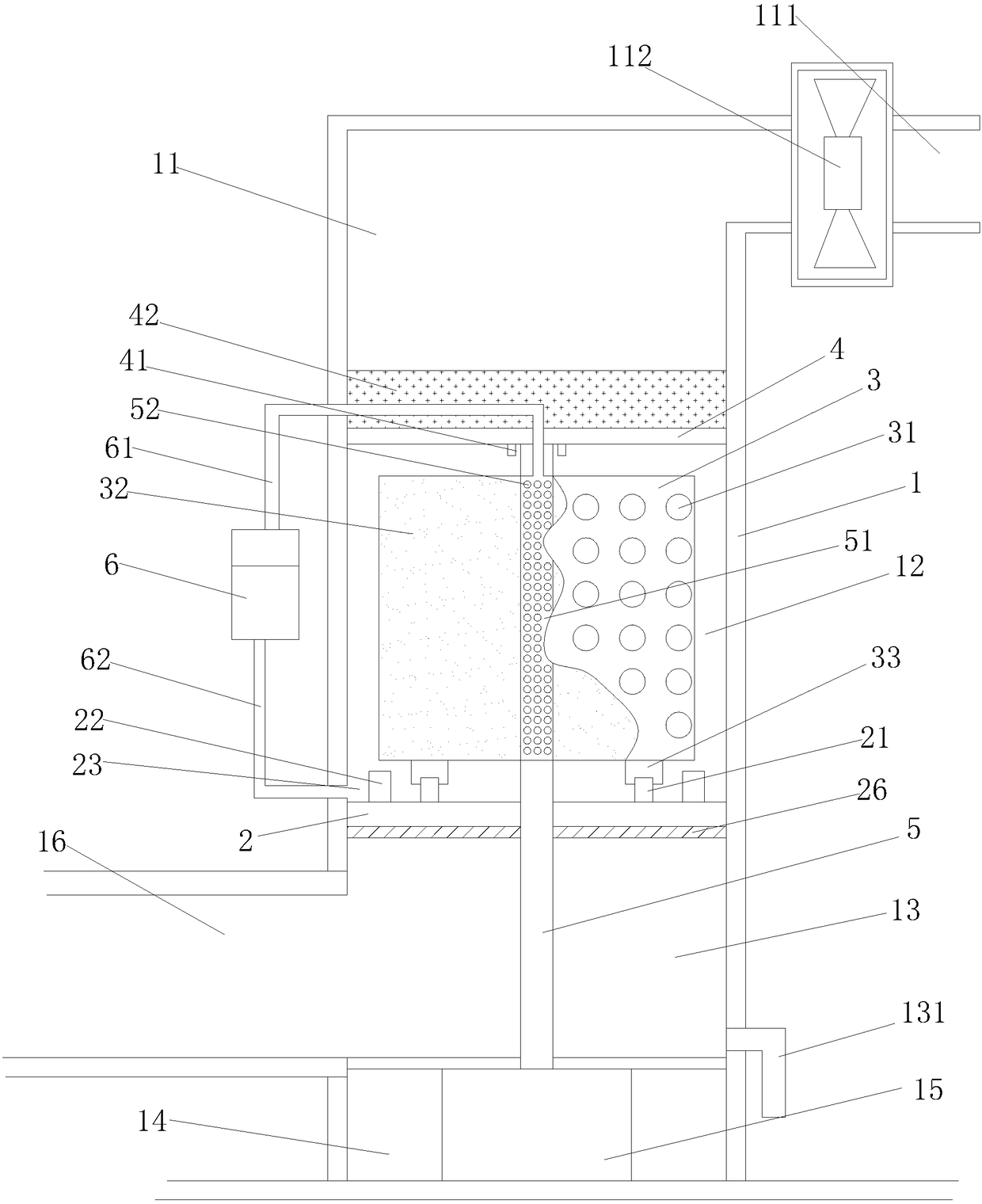

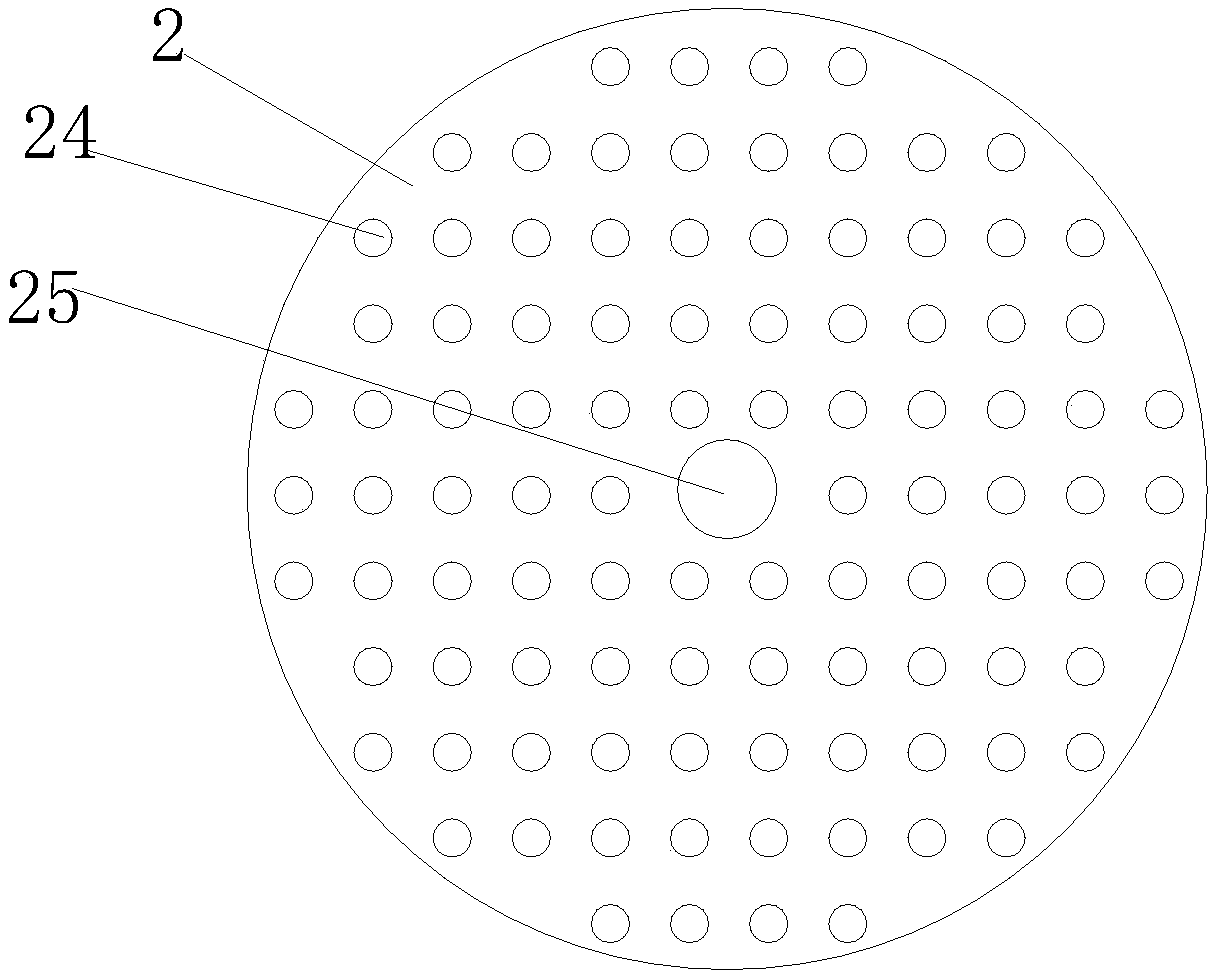

[0020] A filter device for strong acid and strong alkali waste gas, comprising a cylindrical cylinder 1, the cylinder 1 includes an upper exhaust chamber 11, a middle filter chamber 12 and a lower gas collection chamber 13; the lower side of the gas collection chamber 13 A base 14 is provided, a motor 15 is provided in the base 14, an air intake pipe 16 is provided on the side of the gas collection chamber 13, and a circular first partition is provided between the gas collection chamber 13 and the filter chamber 12 2. The upper side of the first partition 2 is concentrically provided with a circular slide rail 21 and a circular blocking piece 22, the circular blocking piece 22 is located outside the circular sliding rail 21, and the circular blocking piece 22 and the lower side of the circular slide rail 21 are all welded with the upper side of the first partition 2, and a circular trough 23 is formed between the circular baffle 22 and the side wall of the filter chamber 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com