Micro three-dimensionak device and preparation method and application thereof

A technology of three-dimensional devices, applied in the field of micro-three-dimensional devices and their preparation, can solve the problems that micro-devices cannot achieve high-precision miniaturization and three-dimensionalization, high manufacturing costs, and reduced manufacturing costs, etc., to achieve mass production and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The first aspect of the present invention provides a method for preparing a miniature three-dimensional device, wherein the method includes the following steps:

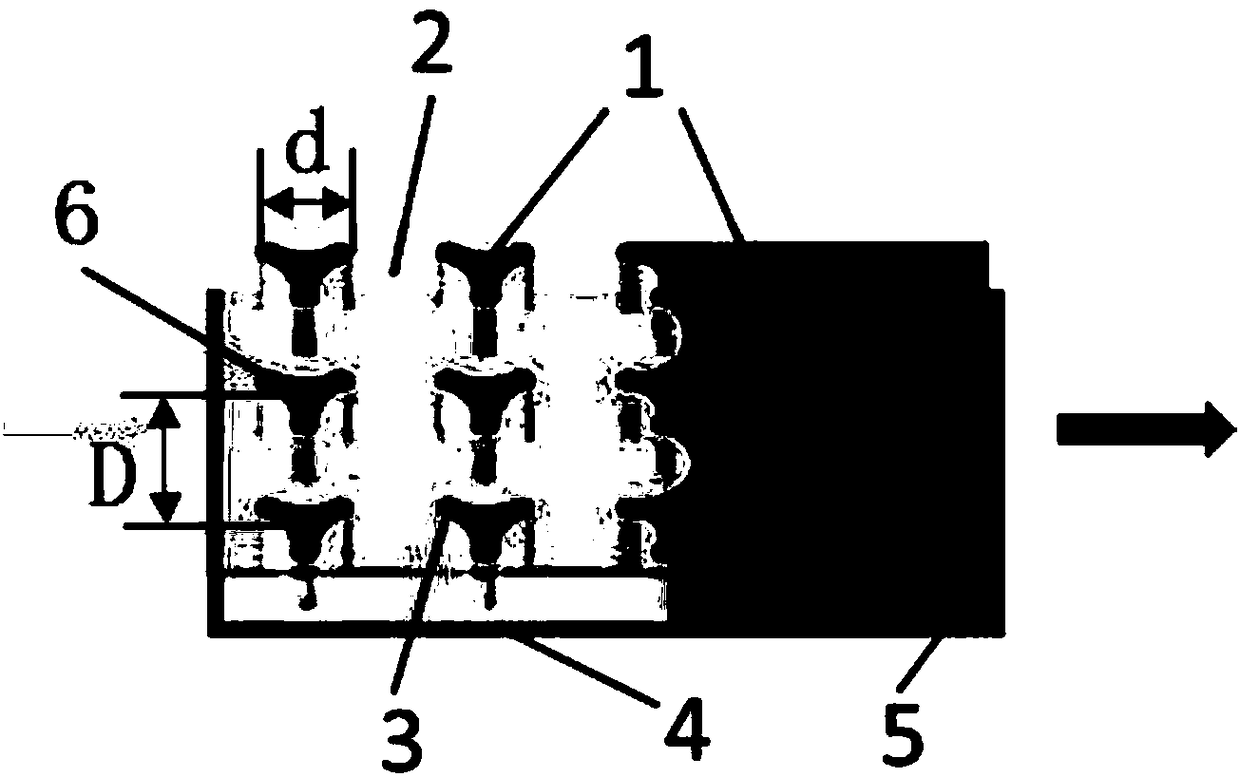

[0028] (A) Prepare a substrate 4 having a plurality of patterned structural units 3 and having hydrophilic properties, wherein the ratio of the distance D between two adjacent patterned structural units 3 to the size d of the patterned structural units 3 is not equal to less than 2;

[0029] (B) Assembling the substrate 4 with a substrate 5 with a flat surface to obtain a microfluidic device with an interlayer;

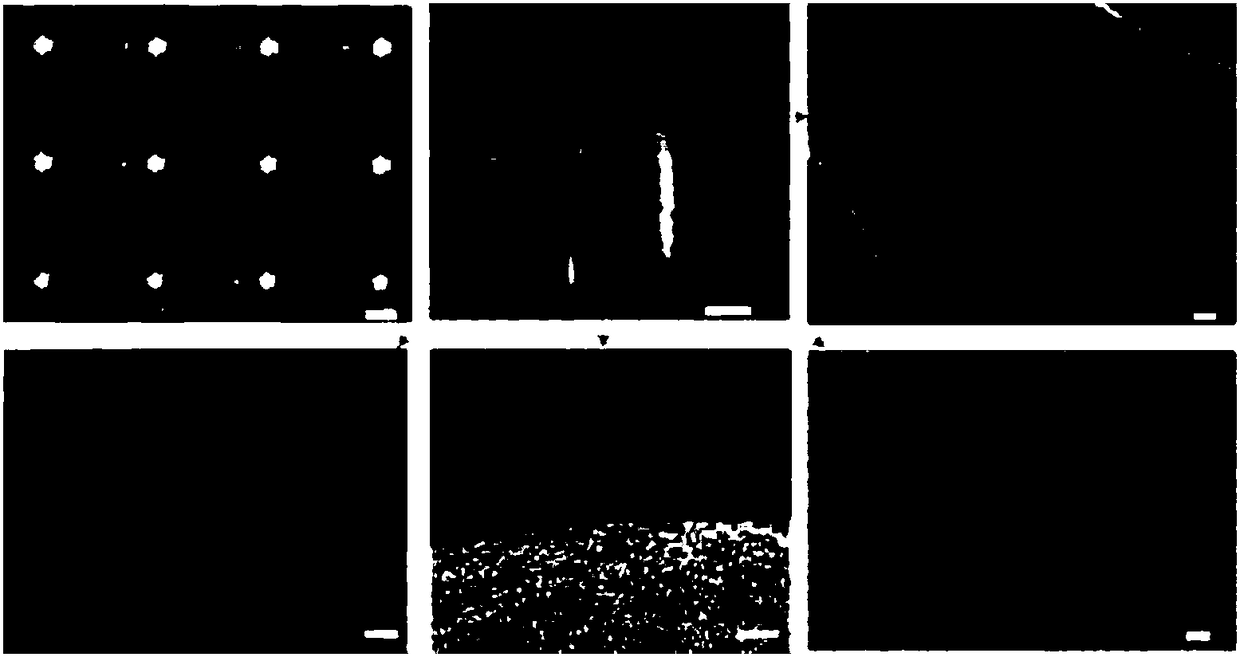

[0030] (C) Inject the first solution 1 containing the first functional material and the first solvent into the microfluidic device and fill the interlayer, then pass the gas 2 to evaporate the first solvent, and form the first functional material on the surface of the patterned structural unit 3 The three-dimensional self-assembled structure of the obtained micro-stereoscopic device containing a sing...

Embodiment 1

[0079] (1) Preparation of substrates with multiple patterned structural units and hydrophilic properties

[0080] Select a square silicon substrate with a side length of 5 inches (such as figure 2 As shown in the label 4 in ), adopt the method of conventional mask optical etching to etch the raised cylindrical silicon pillars (basic units, such as figure 2 6), each circular silicon pillar is 20 μm in height and 10 μm in diameter, and the patterned structural unit (such as figure 2 3) is a triangle composed of three cylinders, the size d of the patterned structural unit is 50 μm, and the distance D between two adjacent patterned structural units is 110 μm.

[0081] Then the substrate was treated with a power of 150W for 300s in an oxygen plasma treatment apparatus to perform hydrophilic treatment.

[0082] (2) Preparation of a microfluidic device with an interlayer

[0083] Place the silicon wafer with multiple patterned structural units horizontally, and then cover it wi...

Embodiment 2

[0092] (1) Preparation of substrates with multiple patterned structural units and hydrophilic properties

[0093] Select a circular silicon wafer substrate with a diameter of 5 inches, and use a conventional mask optical etching method to etch cylindrical silicon pillars on the surface of the silicon wafer. Each circular silicon pillar has a height of 30 μm and a diameter of 15 μm. The patterned structural unit is a triangle composed of three cylinders, the size d of the patterned structural unit is 15 μm, and the distance D between two adjacent patterned structural units is 180 μm.

[0094] Then the substrate was treated with a power of 150W for 300s in an oxygen plasma treatment apparatus to perform hydrophilic treatment.

[0095] (2) Preparation of a microfluidic device with an interlayer

[0096] Place the silicon wafer with multiple patterned structural units horizontally, and then cover it with a glass sheet with a flat surface. The glass sheet has four holes with a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com