Process and equipment for separating mixture of cyclohexanone, cyclohexanol and N,N-dimethylacetamide

A technology of dimethylacetamide and cyclohexanol, which is applied in the chemical industry, can solve the problems that the separation and recovery rate of cyclohexanol has not been significantly improved, and has not been involved, so as to save equipment investment and operation difficulty, reduce heat load, and save cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

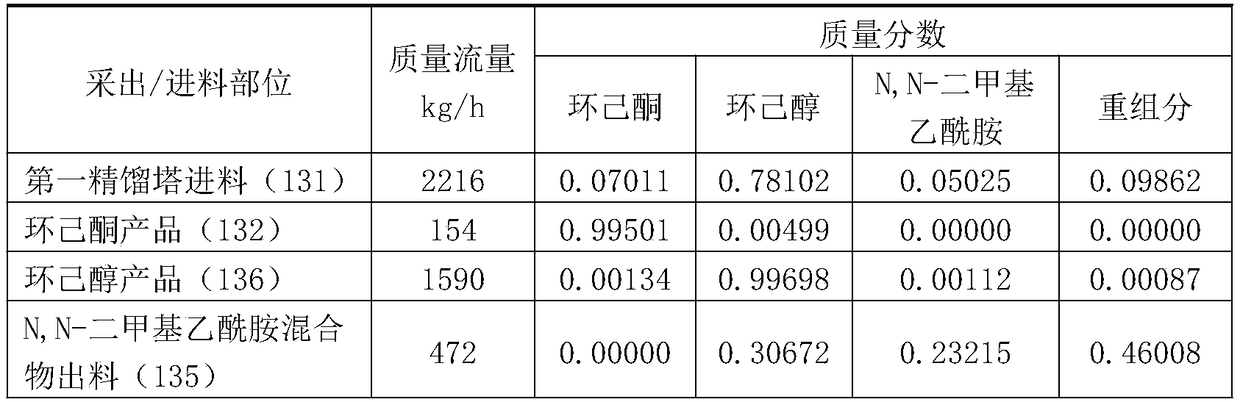

Embodiment 1

[0054] Separation of cyclohexanone from mixtures such as cyclohexanone, cyclohexanol and N,N-dimethylacetamide;

[0055] Separation of cyclohexanol from mixtures such as cyclohexanol and N,N-dimethylacetamide;

[0056] Add extractant to N,N-dimethylacetamide, cyclohexanol and other mixtures;

[0057] A mixture of N,N-dimethylacetamide and extractant, cyclohexanol and heavies was isolated.

Embodiment 2

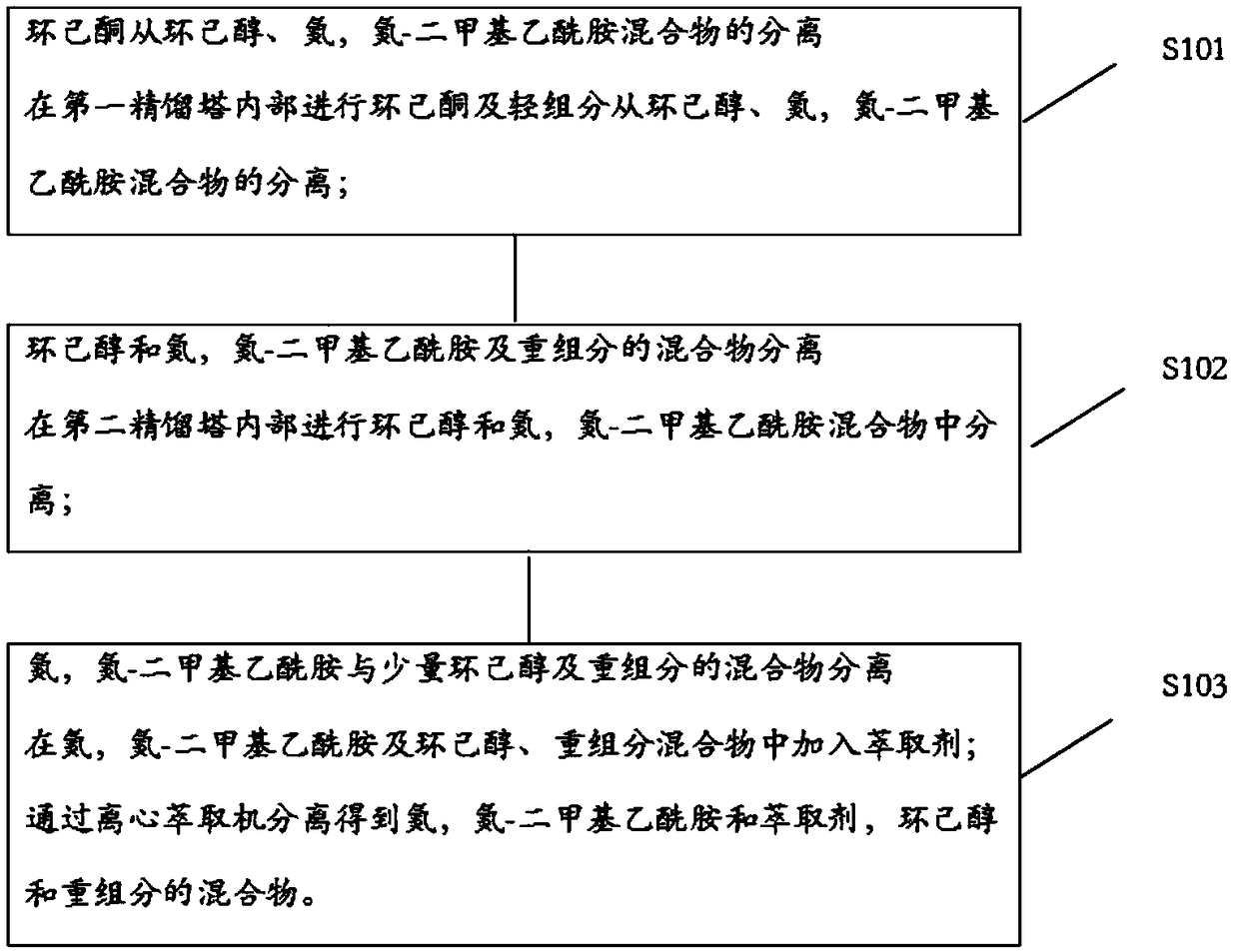

[0059] like figure 1 As shown, the embodiment of the present invention provides a process for separating mixtures such as cyclohexanone, cyclohexanol, and N,N-dimethylacetamide, including:

[0060] Step S101 for separating cyclohexanone and light components from mixtures such as cyclohexanol and N,N-dimethylacetamide;

[0061] Mixtures (131) such as cyclohexanone, cyclohexanol, and N,N-dimethylacetamide enter from the upper part of the first rectification column (T131);

[0062] Separation of cyclohexanone, light components, cyclohexanol, N,N-dimethylacetamide and other mixtures in the first rectification tower (T131);

[0063] After the cyclohexanone and light components at the top of the first rectification tower (T131) enter the first condenser (E132), the liquid phase enters the first reflux tank (V132), and the light components are not condensed in the first reflux tank (V132). Part (134) is drawn into the oil and gas recovery system through the first vacuum pump (P134)...

Embodiment 3

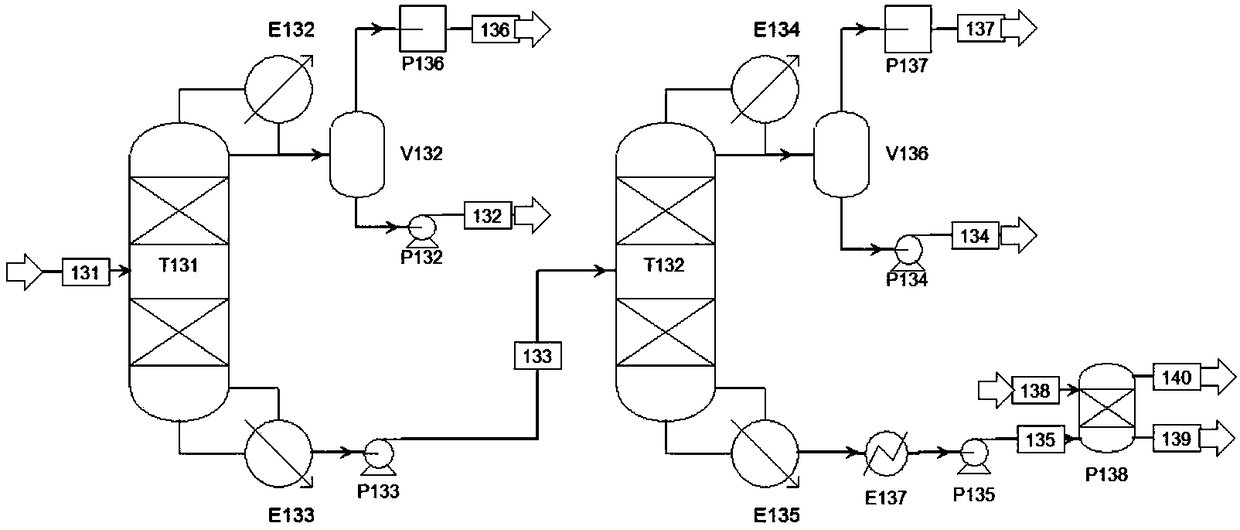

[0077] like figure 2 As shown, the embodiment of the present invention provides a device for separating mixtures such as cyclohexanone, cyclohexanol, N,N-dimethylacetamide, etc., including:

[0078] The first rectification column (T131), the first condenser (E132), the first reflux tank (V132), the first reflux pump (P132), the first vacuum pump (P134), the first reboiler (E133), a Tower discharge pump (P133), second rectification column (T132), second condenser (E134), second reflux tank (V136), second reflux pump (P136), second vacuum pump (P137), second Reboiler (E135), second tower discharge pump (P135), the third condenser (E137), centrifugal extractor (P138); wherein,

[0079] The first condenser (E132) is arranged between the top of the first rectifying column (T131) and the first reflux tank (V132);

[0080] The first reflux pump (P132) is arranged between the top of the first reflux tank (V132) and the first rectifying column (T131);

[0081] The first vacuum pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com