A method for preparing phenolic airgel by normal pressure drying method and prepared phenolic airgel

A technology of normal pressure drying and aerogel, which is applied in the field of phenolic airgel prepared by normal pressure drying method, and can solve the problem of complex preparation process of phenolic aerogel, poor performance of phenolic aerogel, phenolic gas Low gel strength and other issues, to achieve the effect of reducing cost and operation complexity, low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

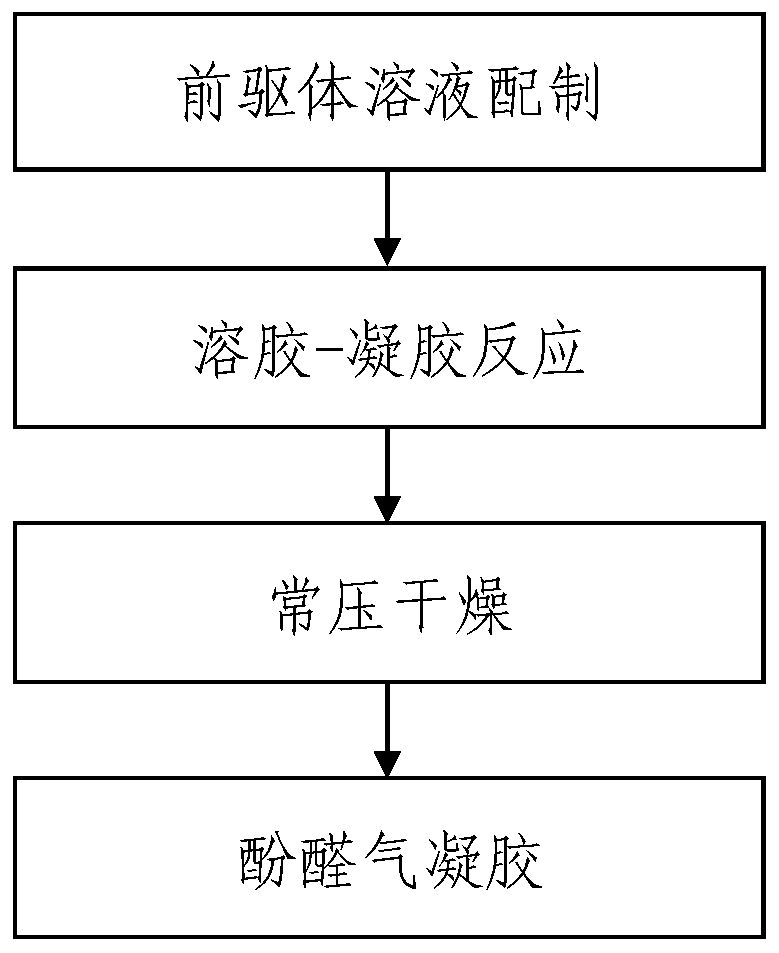

Method used

Image

Examples

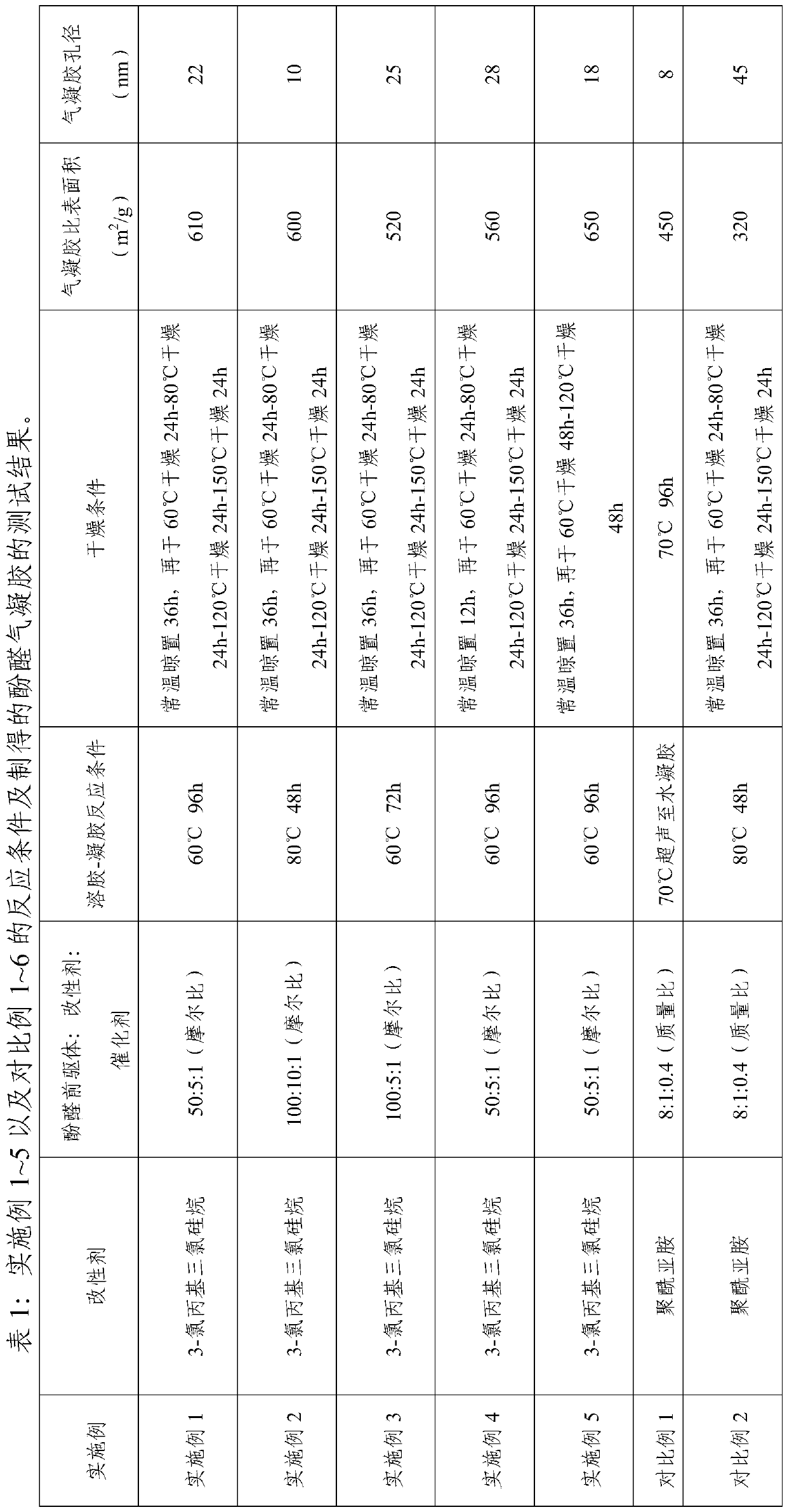

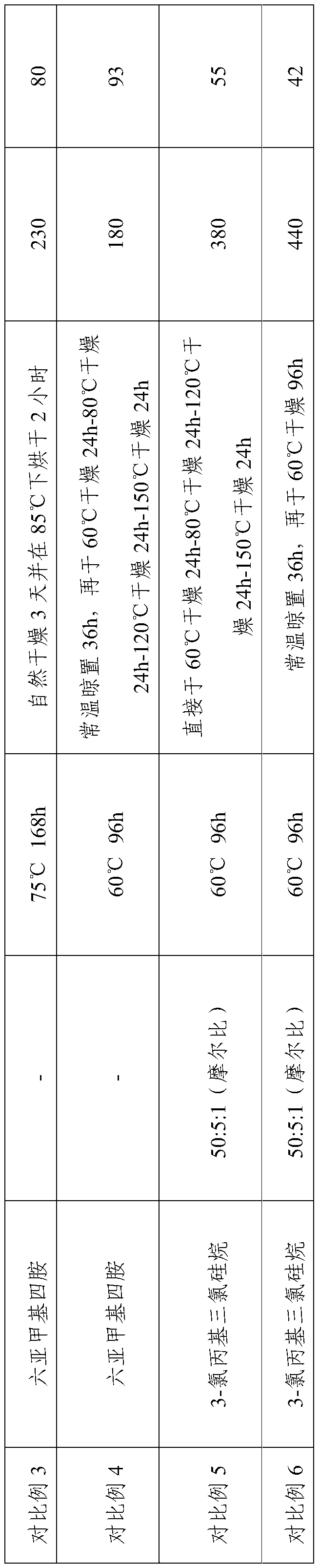

Embodiment 1

[0043] Resorcinol+formaldehyde phenolic precursor system is adopted, 3-chloropropyl trichlorosilane is used as modifier, the catalyst is 0.1mol / L hydrochloric acid solution, and the organic solvent is isopropanol; wherein the concentration of phenolic precursor is 10wt% , the molar ratio of phenolic precursor:modifier:catalyst is 50:5:1; the above raw materials are mixed and stirred evenly to obtain the precursor solution.

[0044] The precursor solution was placed in a sealed ampoule, then placed in a water bath at 60°C, and reacted (sol-gel reaction) for 96 hours to obtain a phenolic alcohol gel.

[0045] Take the phenolic alcohol gel out of the sealed ampoule, place it in the air at room temperature for 36 hours, and then dry it in an oven. The drying procedure in the oven is: first dry at 60°C under normal pressure for 24 hours, and then heat up Dry at 80°C under normal pressure for 24 hours, then raise the temperature to 120°C and dry at normal pressure for 24 hours, and ...

Embodiment 2

[0048] Resorcinol+formaldehyde phenolic precursor system is adopted, 3-chloropropyl trichlorosilane is used as modifier, the catalyst is 0.1mol / L hydrochloric acid solution, and the organic solvent is isopropanol; wherein the concentration of phenolic precursor is 10wt% , the molar ratio of phenolic precursor:modifier:catalyst is 100:10:1; the above raw materials are mixed and stirred evenly to obtain the precursor solution.

[0049] The precursor solution was placed in a sealed ampoule, then placed in a water bath at 80°C, and reacted for 48 hours to obtain a phenolic alcohol gel.

[0050] Take the phenolic alcohol gel out of the sealed ampoule, place it in the air at room temperature for 36 hours, and then dry it in an oven. The drying procedure in the oven is: first dry at 60°C under normal pressure for 24 hours, and then heat up Dry at 80°C under normal pressure for 24 hours, then raise the temperature to 120°C and dry at normal pressure for 24 hours, and finally raise the...

Embodiment 3

[0053] Resorcinol+formaldehyde phenolic precursor system is adopted, 3-chloropropyl trichlorosilane is used as a modifying agent, the catalyst is 0.1mol / L potassium hydroxide solution, and the organic solvent is isopropanol; wherein the concentration of the phenolic precursor is 15 wt%, the molar ratio of phenolic precursor:modifier:catalyst is 100:5:1; the above raw materials are mixed and stirred evenly to obtain a precursor solution.

[0054] The precursor solution was placed in a sealed ampoule, then placed in a 60°C water bath, and reacted for 72 hours to obtain a phenolic alcohol gel.

[0055] Take the phenolic alcohol gel out of the sealed ampoule, place it in the air at room temperature for 36 hours, and then dry it in an oven. The drying procedure in the oven is: first dry at 60°C under normal pressure for 24 hours, and then heat up Dry at 80°C under normal pressure for 24 hours, then raise the temperature to 120°C and dry at normal pressure for 24 hours, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com