Modified recycled special material for pe straight wall pipe

A technology for recycled materials and pipes, which is applied in the field of PE straight-walled pipes and its special recycled materials and its preparation. It can solve the problems of uncontrollable performance of recycled materials, few types of PE, and different performances of HDPE, so as to improve physical and chemical properties, status and performance indicators. The effect of improvement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0030] In Example 2, the HDPE film grade crushed material used is HDPE black film crushed material, and the MRF is 1.5; the HDPE blow molding grade low-melt finger crushed material used is HDPE big blue barrel crushed material, and the MRF is 0.5; the HDPE pipe used The crushed material of high-grade low-grade melting finger is HDPE clarinet crushed material, and the MRF is 0.8; the crushed material of HDPE blow-molding medium-melt finger used is PE washing and chemical product crushed material, and the MRF is 2.2; the LDPE high-pressure particles used are recycled LDPE film grade Particles, with an MRF of 6, were purchased from Jinhuan, Thailand; the HDPE pipe-grade ultra-low melt index crushed material used was HDPE natural gas pipeline crushed material, with an MRF of 0.06; the black masterbatch used was purchased from Jiangsu Yazhong Environmental Protection Technology Co., Ltd., and the black masterbatch Grade 8068A.

Embodiment 3

[0031] In Example 3 and Comparative Examples 1-3, the HDPE film-grade crushed material used was HDPE black film crushed material, and the MRF was 1.2; the HDPE blow molding grade low-melt finger crushed material used was HDPE large blue barrel crushed material, and the MRF was 0.4 ;The HDPE pipe grade low-melt finger crushed material used is HDPE clarinet pipe crushed material, and the MRF is 0.5; the HDPE blow molding grade medium-melt finger crushed material used is PE washing and chemical product crushed material, and the MRF is 1.9; the LDPE high-pressure granules used It is LDPE film-grade recycled particles with an MRF of 5, purchased from Jinhuan, Thailand; the HDPE pipe-grade ultra-low melting index crushed material used is HDPE natural gas pipeline crushed material, with an MRF of 0.08; the black masterbatch used is purchased from Jiangsu Yazhong Environmental Protection Technology Ltd, Black Mother Grade No. 8068A.

Embodiment 1

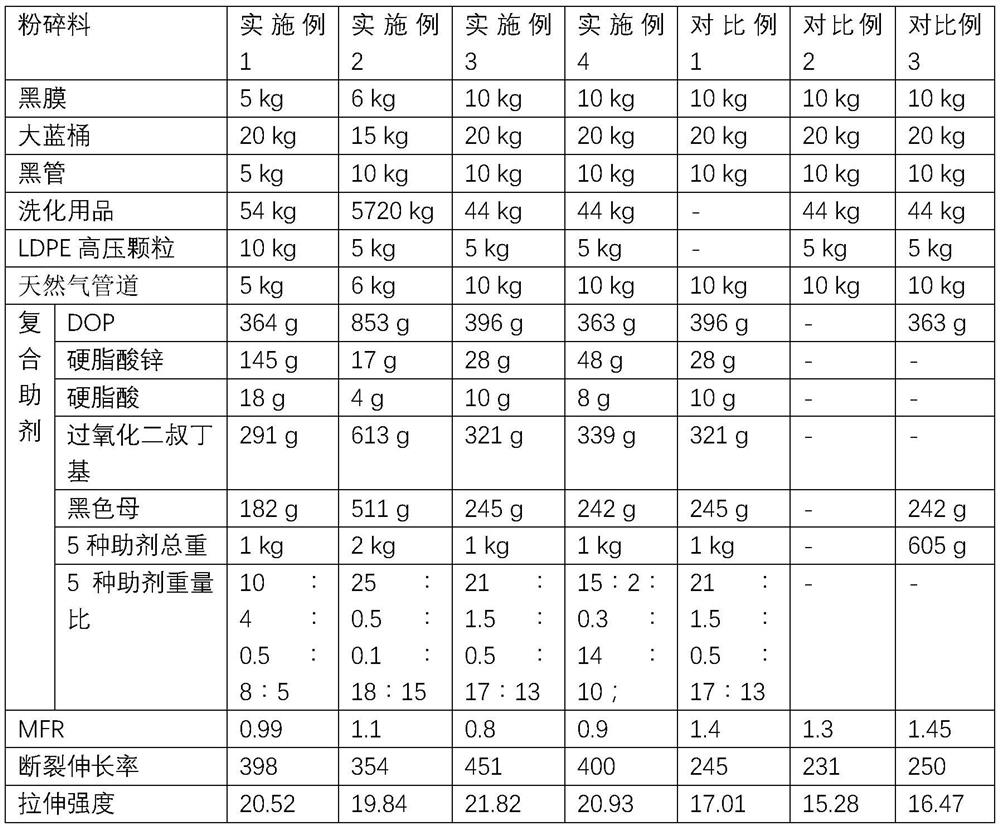

[0033] A modified PE regenerated material for PE straight-wall pipes, the components of which are shown in Table 1;

[0034] The preparation method of this recycled material is:

[0035] 1) Prepare materials according to the above-mentioned components and parts by weight;

[0036] 2) Put the prepared raw materials into the mixer for full mixing;

[0037] 3) After the granulator is preheated, use the feeder to put the stirred raw materials into the granulator for heating and melting, and the melting temperature is 200°C;

[0038] 4) The molten material is extruded by a screw, and cut into granules by a hot cutting machine.

[0039] Table 1

[0040]

[0041] The components of the modified PE recycled materials for PE straight-wall pipes provided in Examples 2-4 and Comparative Examples 1-3 are shown in Table 1 respectively; the preparation method of the recycled materials is the same as in Example 1. The performance indexes of the recycled materials prepared in each embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com