Preparation method of epoxy resin used for automobile tyre terylene tyre fabric impregnation

A technology for epoxy resin and automobile tires, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of high cost and high price of polyester cord fabric, and achieve excellent mechanical properties, low cost, and enhanced tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of epoxy resin for dipping polyester cord fabric of automobile tires in this embodiment comprises the following steps:

[0017] In the first step, the temperature of polypropylene glycol diglycidyl ether and diethylene glycol diglycidyl ether is respectively raised to 70°C for distillation under reduced pressure, and part of the water and toluene are removed until the water solubility reaches 99%;

[0018] In the second step, by weight, 18 parts of propylene glycol diglycidyl ether and 75 parts of diethylene glycol diglycidyl ether are heated to 60°C, and 2 parts of sodium dodecylbenzenesulfonate and 0.1 parts of The simethicone oil is kept warm for 1 hour to obtain epoxy resin for dipping polyester cord fabric of automobile tires.

Embodiment 2

[0020] The preparation method of epoxy resin for dipping polyester cord fabric of automobile tires in this embodiment comprises the following steps:

[0021] In the first step, glycerol triglycidyl ether and ethylene glycol diglycidyl ether are respectively heated to 80°C for vacuum distillation to remove part of water and toluene until the water solubility reaches 99%;

[0022] In the second step, by weight, 20 parts of glycerol triglycidyl ether A and 77.3 parts of ethylene glycol diglycidyl ether are warmed up to 60°C, and 2.6 parts of sodium dodecylbenzenesulfonate and 0.1 part of simethicone oil was incubated for 2 hours to obtain an epoxy resin for automobile tire polyester cord impregnation.

Embodiment 3

[0024] The preparation method of epoxy resin for dipping polyester cord fabric of automobile tires in this embodiment comprises the following steps:

[0025] In the first step, dipropylene glycol diglycidyl ether and butyl glycidyl ether were respectively heated to 90°C for distillation under reduced pressure to remove part of the water and toluene until the water solubility reached 99%;

[0026] In the second step, by weight, 22 parts of dipropylene glycol diglycidyl ether and 78 parts of butyl glycidyl ether are heated to 60°C, and 3 parts of sodium dodecylbenzenesulfonate and 02 parts of di Methyl silicone oil, heat preservation 3 hours, obtains the epoxy resin for automobile tire polyester cord fabric impregnation.

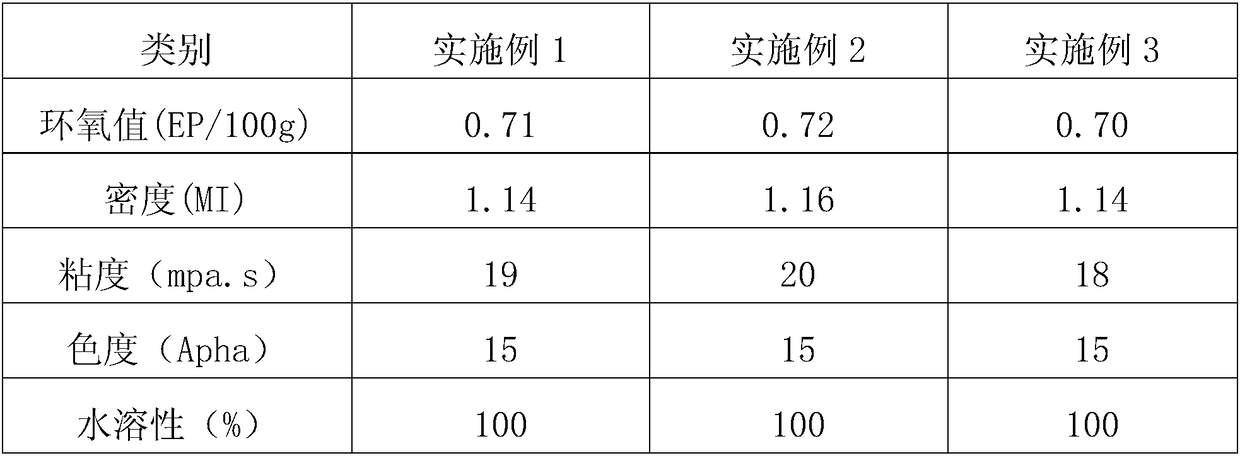

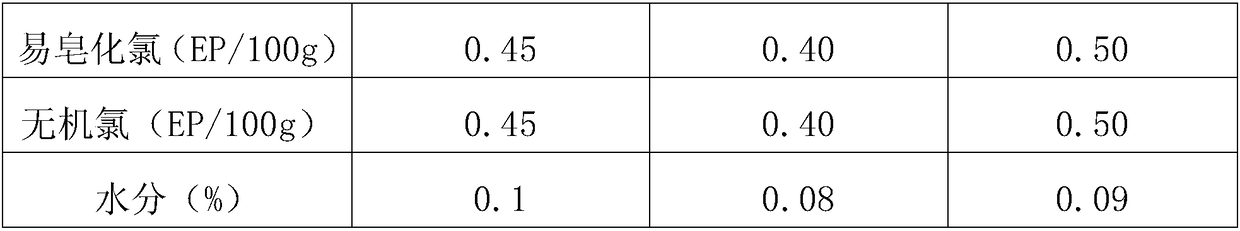

[0027] The performance parameter of embodiment 1-3 is as follows:

[0028]

[0029]

[0030] Thus, it is concluded that the epoxy resin for automobile tire polyester cord dipping prepared by the method of the present invention has a higher epoxy value, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap