Minisized gas-chromatographic-column chip and preparation method thereof

A micro gas chromatography and chromatographic technology, which is applied in the field of micro gas chromatography column chip and its preparation, can solve the problems of large volume and high power consumption of the chromatographic column chip, and achieve the effect of improving efficiency and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

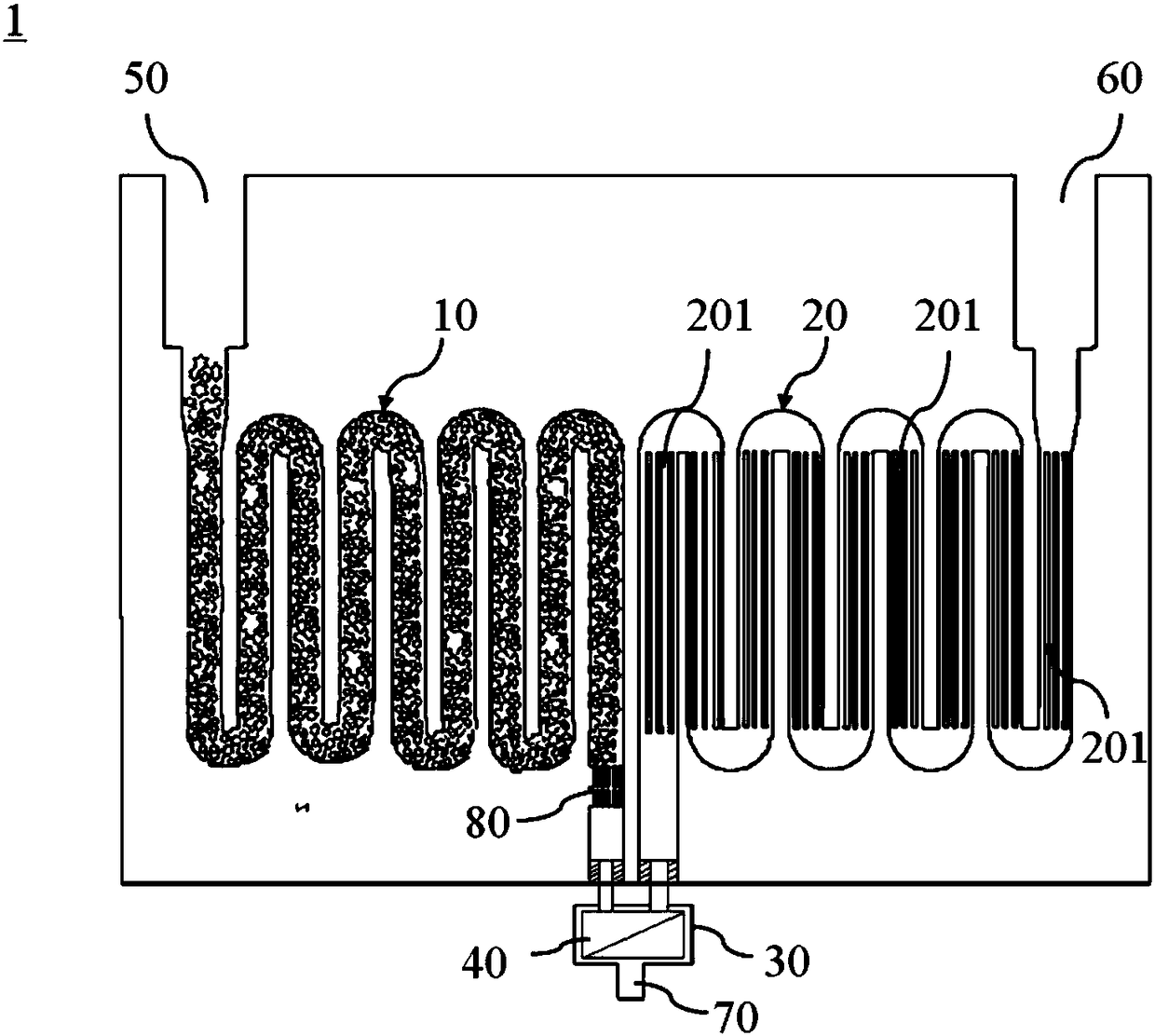

[0036] figure 1 A schematic structural diagram of a micro gas chromatography column chip 1 according to the first embodiment of the present invention is shown. Such as figure 1 As shown, the micro gas chromatographic column chip 1 includes two mutually independent chromatographic channels, a connecting channel and a solenoid valve 40 . The two chromatographic channels are respectively the first chromatographic channel 10 and the second chromatographic channel 20 . The first chromatographic channel 10 is filled with a solid stationary phase, and the second chromatographic channel 20 is filled with a liquid or colloidal stationary phase. The connecting channel is arranged between the first chromatographic channel 10 and the second chromatographic channel 20 , and is used to communicate with the first chromatographic channel 10 and the second chromatographic channel 20 . The solenoid valve 40 is located in the connecting passage for opening or closing the connecting passage. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com