Functional image tile and manufacturing method therefor

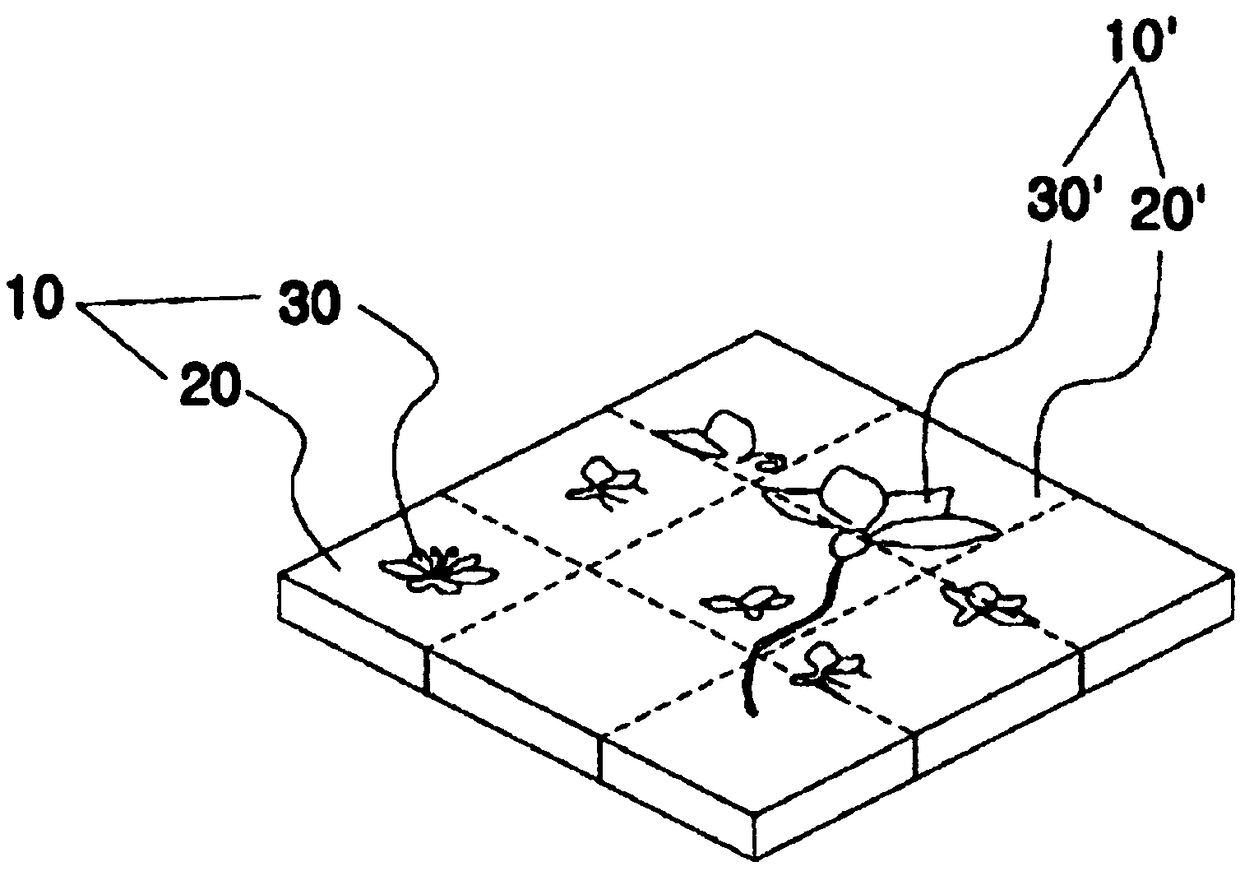

一种功能性、印花的技术,应用在印刷、印刷工艺、黏土制品等方向,能够解决图像砖生产效率低下、搬运或安装易破碎、搬运/保管不便等问题,达到湿度调节能力优秀、防止图像剥离或因水分而浸染、缓解压力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

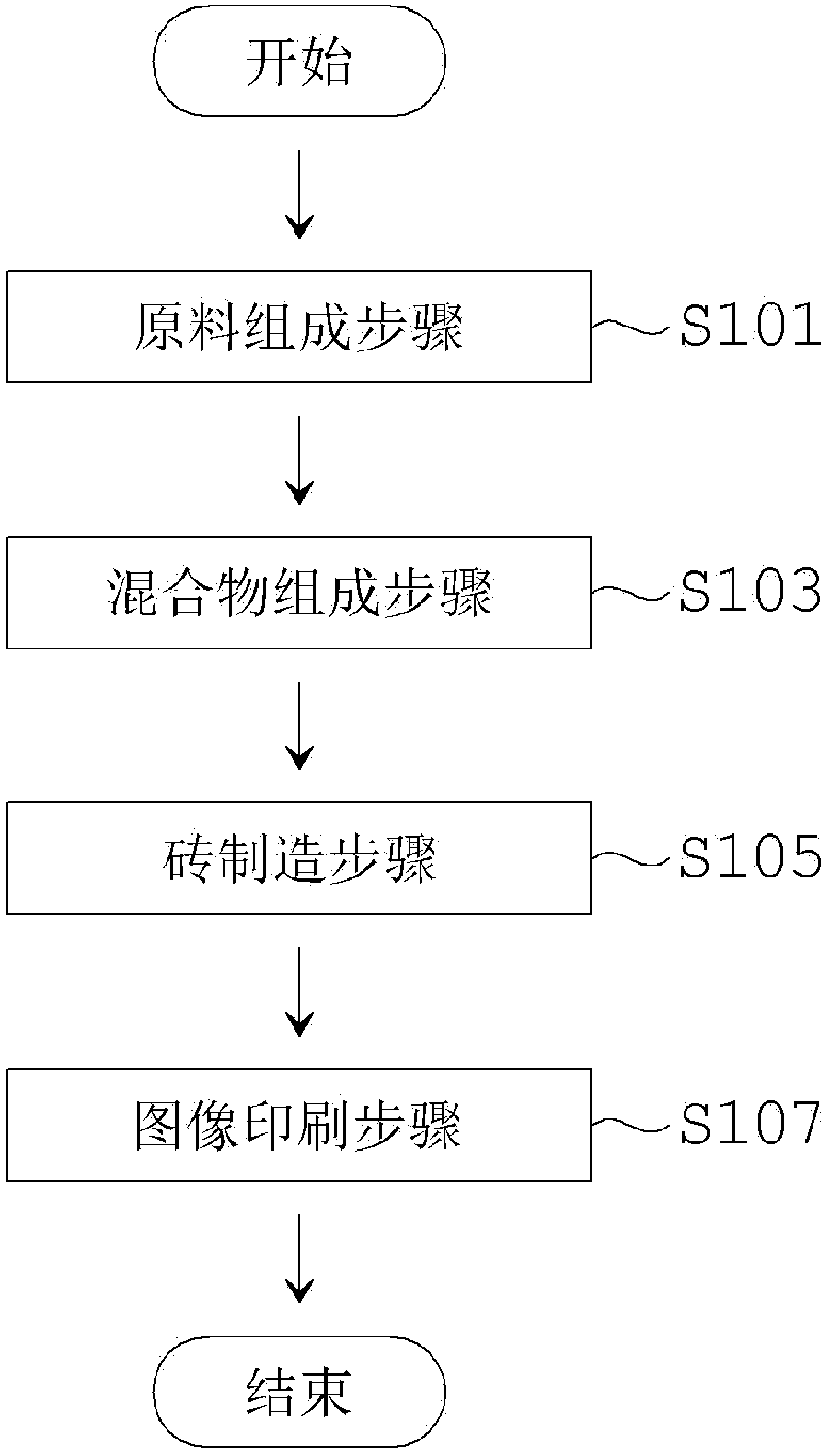

[0063] After mixing 60% by weight of gypsum and 40% by weight of water to form a raw material, 25 parts by weight of loess, 9 parts by weight of basalt fiber, and 7 parts by weight of mulberry fiber were mixed with respect to 100 parts by weight of the raw material to form a mixture.

[0064] After putting the mixture into the molding frame and solidifying it, it was released from the molding frame to form a brick, and then, an image was printed on the surface of the brick to manufacture the functional printed tile of the present invention.

Embodiment 2

[0066] After mixing 60% by weight of gypsum and 40% by weight of water to form a raw material, 5 parts by weight of loess, 5 parts by weight of basalt fiber and 5 parts by weight of mulberry fiber were mixed with respect to 100 parts by weight of the raw material to form a mixture.

[0067] After putting the mixture into the molding frame and solidifying it, it was released from the molding frame to form a brick, and then, an image was printed on the surface of the brick to manufacture the functional printed tile of the present invention.

Embodiment 3

[0069] After mixing 60 wt% of gypsum and 40 wt% of water to form a raw material, 30 wt. parts of loess, 10 wt.

[0070] After putting the mixture into the molding frame and solidifying it, it was released from the molding frame to form a brick, and then, an image was printed on the surface of the brick to manufacture the functional printed tile of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com