A kind of low-temperature puffed yoghurt soluble beans and preparation method thereof

A low-temperature puffing and yogurt technology, which is applied in the directions of milk preparations, other dairy products, bacteria used in food preparation, etc., can solve the problems of increasing production cost, short shelf life, inconvenient portability, etc., avoiding energy waste, The effect of reducing production costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

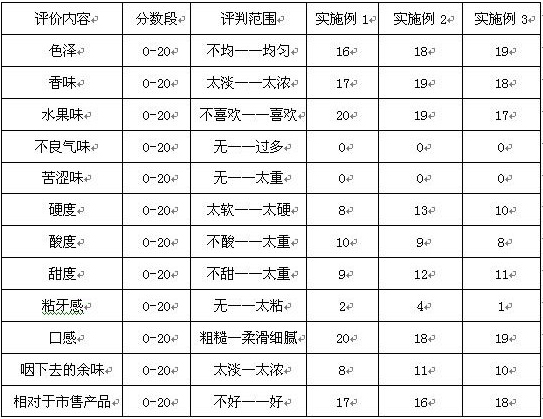

Examples

Embodiment 1

[0031] A low-temperature puffed yoghurt soluble bean with live bacteria, which takes the following raw materials in mass proportions;

[0032] Yogurt 120, sucrose 35, skimmed milk powder 50, whipping cream 35, maltodextrin 12, tapioca starch 13;

[0033] The yogurt soluble beans of this embodiment are prepared by the following steps:

[0034] (1) Equipment preparation

[0035] Clean the utensils required for the preparation of yogurt soluble beans, sterilize them with water vapor at 85°C, and cool down to dry;

[0036] (2), raw material preparation

[0037] Put the whipped cream in a container and whip it to form a solid state;

[0038] (3), raw material mixing

[0039] Weigh and mix the other components except the whipped cream according to the proportion by weight, slowly add them to the container containing the whipped cream gradually, and stir evenly;

[0040] (4), material molding

[0041] Process and shape the mixed material through soluble bean forming equipment o...

Embodiment 2

[0048] A low-temperature puffed yoghurt soluble bean with live bacteria, which takes the following raw materials in mass proportions;

[0049] Yogurt 100, sucrose 30, skimmed milk powder 40, whipping cream 20, maltodextrin 10, tapioca starch 10;

[0050]The yogurt soluble beans of this embodiment are prepared by the following steps:

[0051] (1) Equipment preparation

[0052] Clean the utensils required for the preparation of yogurt soluble beans, sterilize them with 95°C steam, and cool down to dry;

[0053] (2), raw material preparation

[0054] Put the whipped cream in a container and whip it to form a solid state;

[0055] (3), raw material mixing

[0056] Weigh and mix the other components except the whipped cream according to the proportion by weight, slowly add them to the container containing the whipped cream gradually, and stir evenly;

[0057] (4), material molding

[0058] Process and shape the mixed material through soluble bean forming equipment or forming ...

Embodiment 3

[0065] A low-temperature puffed yoghurt soluble bean with live bacteria, which takes the following raw materials in mass proportions;

[0066] Yogurt 150, sucrose 50, skimmed milk powder 60, whipped cream 50, maltodextrin 15, tapioca starch 15;

[0067] The yogurt soluble beans of this embodiment are prepared by the following steps:

[0068] (1) Equipment preparation

[0069] Clean the utensils required for the preparation of yogurt soluble beans, sterilize them with 90°C steam, and cool down to dry;

[0070] (2), raw material preparation

[0071] Put the whipped cream in a container and whip it to form a solid state;

[0072] (3), raw material mixing

[0073] Weigh and mix the other components except the whipped cream according to the proportion by weight, slowly add them to the container containing the whipped cream gradually, and stir evenly;

[0074] (4), material molding

[0075] Process and shape the mixed material through soluble bean forming equipment or forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com