Rotary demister

A demister and rotating technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of difficult processing, high processing and manufacturing costs, complex technical structure, etc., to reduce mist entrainment, Increase the contact area and facilitate the effect of trapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

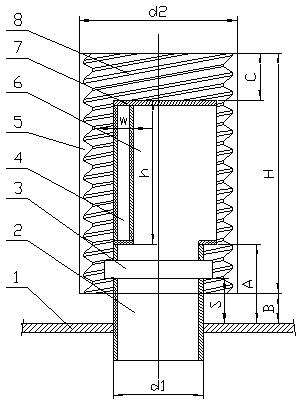

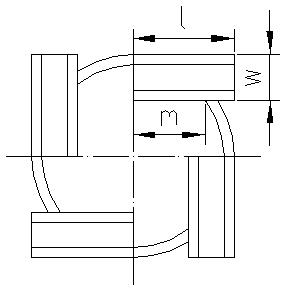

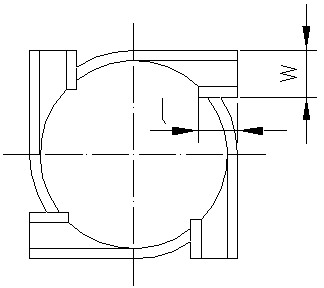

[0049] Apply the demister of the present invention to a wet scrubber to purify flue gas. The diameter of the outer cylinder of the demister assembly is 180 mm, the diameter of the air riser is 80 mm, and 4 rectifying channels are used. The length of the rectifying channel is 40 mm and the width is 20 mm. The height is 40mm, the end of the side wall II is flush with the inner wall of the air riser, the distance A between the bottom of the rectification channel and the tray is 80mm, the distance S between the bottom of the bearing and the tray is 40mm, and the distance C between the upper edge of the outer cylinder and the upper edge of the air riser is 170mm, the distance B from the lower edge of the outer cylinder to the tray is 20mm, and the total height H of the outer cylinder is 270mm; the internal thread on the outer cylinder adopts a single thread ordinary thread, the major diameter D of the thread is 177mm, the middle diameter D2 of the thread is 174mm, and the minor diame...

Embodiment 2

[0051] Apply the demister of the present invention to a wet scrubber to purify flue gas. The diameter of the outer cylinder of the demister assembly is 180 mm, the diameter of the air riser is 80 mm, and 4 rectifying channels are used. The length of the rectifying channel is 40 mm and the width is 20 mm. The height is 40mm, the end of the side wall II is flush with the inner wall of the air riser, the distance A between the bottom of the rectification channel and the tray is 80mm, the distance S between the bottom of the bearing and the tray is 40mm, and the distance C between the upper edge of the outer cylinder and the upper edge of the air riser is 170mm, the distance B from the lower edge of the outer cylinder to the tray is 20mm, and the total height H of the outer cylinder is 270mm; when the internal thread on the outer cylinder adopts five-line trapezoidal thread, the major diameter D of the thread is 177mm, the middle diameter D2 of the thread is 166mm, and the minor dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com