Phosphorus adsorbent based on water supply plant iron-aluminum mud and preparation method of phosphorus adsorbent

A technology of phosphorus adsorbent and iron-aluminum mud, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult and fast removal of phosphorus and slow phosphorus adsorption, Achieve the effect of low cost, simple method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) After collecting fresh iron-aluminum mud from the dehydrated water supply plant, it is dried and ground into particles with a particle size of less than 0.178 mm.

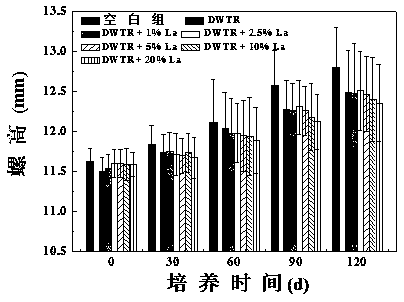

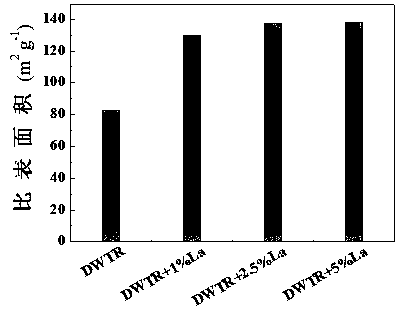

[0036] (2) Put lanthanum chloride into the water so that the mass fraction of lanthanum is 0%, 1%, 2.5%, 5%, 10% and 20% respectively, and adjust the pH with NaOH solution, adjust once every hour for the first 4 hours Adjust the pH to 8~9, then let it stand for 12 hours and adjust it once more to obtain a weakly alkaline lanthanum suspension with a pH of 9, which is a mixture containing lanthanum hydroxide and lanthanum ions ;

[0037] (3) Mix the dry iron-aluminum sludge obtained in step (1) with the weakly alkaline lanthanum suspension at a mass ratio of 1:1, so that the mass of lanthanum is 0% of the iron-aluminum sludge of the water supply plant. , 1%, 2.5%, 5%, 10% and 20%;

[0038] (4) Mix the solution thoroughly with a stirrer, and incubate the mixed solution at 60 ℃ for 5 h, and then at room temperatu...

Embodiment 2

[0041] (1) After collecting fresh iron-aluminum mud from the dehydrated water supply plant, it is dried and ground into particles with a particle size of less than 0.178 mm.

[0042] (2) Put lanthanum chloride into water so that the mass fraction of lanthanum is 5%, and adjust the pH with KOH solution. Adjust the pH to 8-9 every hour for the first 4 hours, then let it stand for 12 hours, and then adjust Once, a weakly basic lanthanum suspension with a pH of 8 is obtained, and the weakly basic lanthanum suspension is a mixture containing lanthanum hydroxide and lanthanum ions;

[0043] (3) Mix the dried iron-aluminum mud of the water supply plant obtained in step (1) with the weakly alkaline lanthanum suspension at a mass ratio of 1:1 so that the mass of lanthanum is 5% of the iron-aluminum mud of the water supply plant;

[0044] (4) Mix the solution thoroughly with a stirrer, and incubate the mixed solution at 80°C for 8 hours, and then at 20°C to 30°C for 36 hours;

[0045] (5) Dry t...

Embodiment 3

[0046] Example 3 Comparative Example

[0047] (1) After collecting the iron-aluminum mud from the fresh dehydrated water supply plant, it is dried and ground into particles with a particle size of less than 0.178 mm;

[0048] (2) Put lanthanum chloride into the water so that the mass fraction of lanthanum is 10%, 5% and 0.5%, and adjust the pH with NaOH solution. Adjust the pH to 8-9 every hour for the first 4 hours, and then let it stand still 12 h, adjust once more to obtain a weakly alkaline lanthanum suspension with a pH of 8, which is a mixture containing lanthanum hydroxide and lanthanum ions;

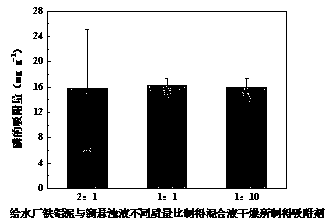

[0049] (3) Mix the dried iron-aluminum mud from the water supply plant obtained in step (1) with the weakly alkaline lanthanum suspension in a mass ratio of 2:1, 1:1, and 1:10, so that the mass of lanthanum is relative to The iron and aluminum mud of the water supply plant are the same, that is, both are 5%;

[0050] (4) Mix the solution thoroughly with a stirrer, and incubate the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com