Nanoparticle electrocatalyst with Pt@Pd core-shell structure as well as preparation method and application of nanoparticle electrocatalyst

A nanoparticle and electrocatalyst technology, applied in the field of electrocatalytic materials, can solve the problems of large size, lack of theoretical understanding, affecting the stability and life of electrocatalyst, and achieve the effect of mild experimental conditions and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of Pd seeds: Weigh 0.1mmol cetyltrimethylammonium bromide and dissolve it in an appropriate amount of water, then add 0.01mmolH 2 PdCl 4 , so that the total volume of the solution is 20ml. Preheat in a water bath at 50°C for 5 minutes. Add 0.01 mmol of ascorbic acid to the flask, and magnetically stir for 1 h to obtain a Pd seed solution.

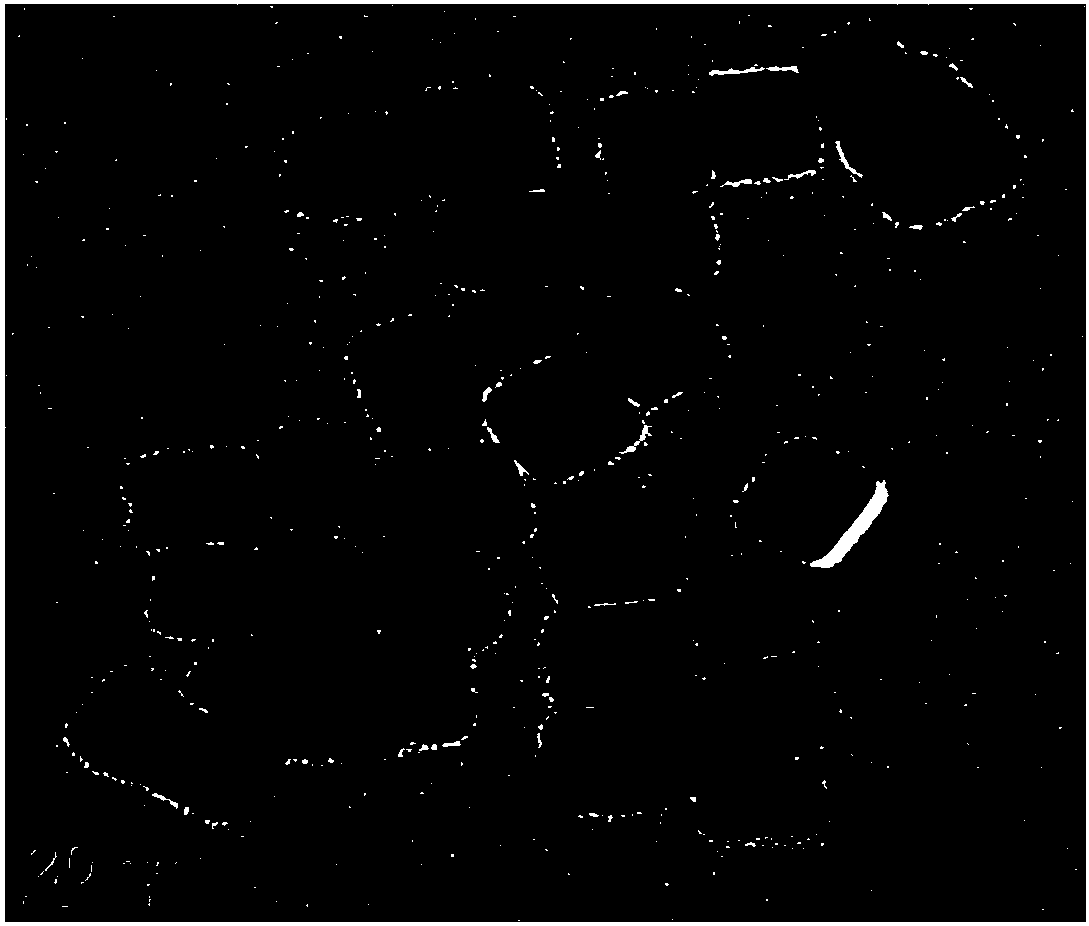

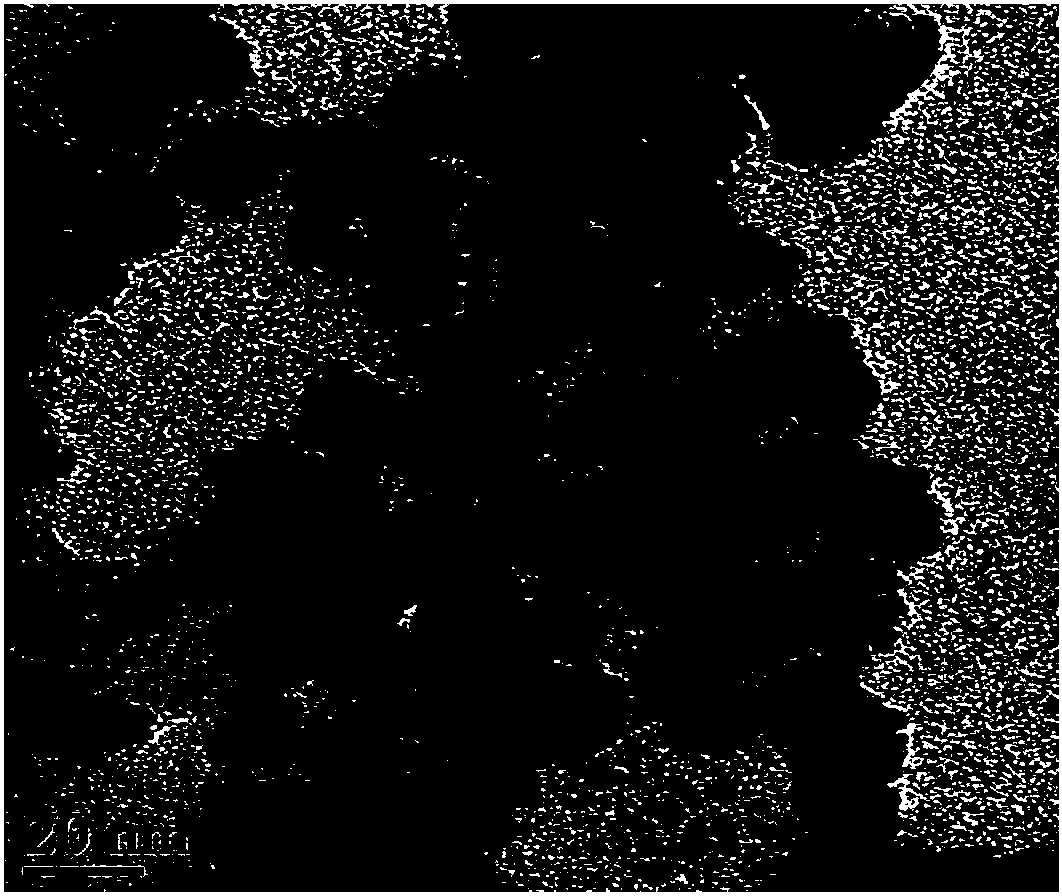

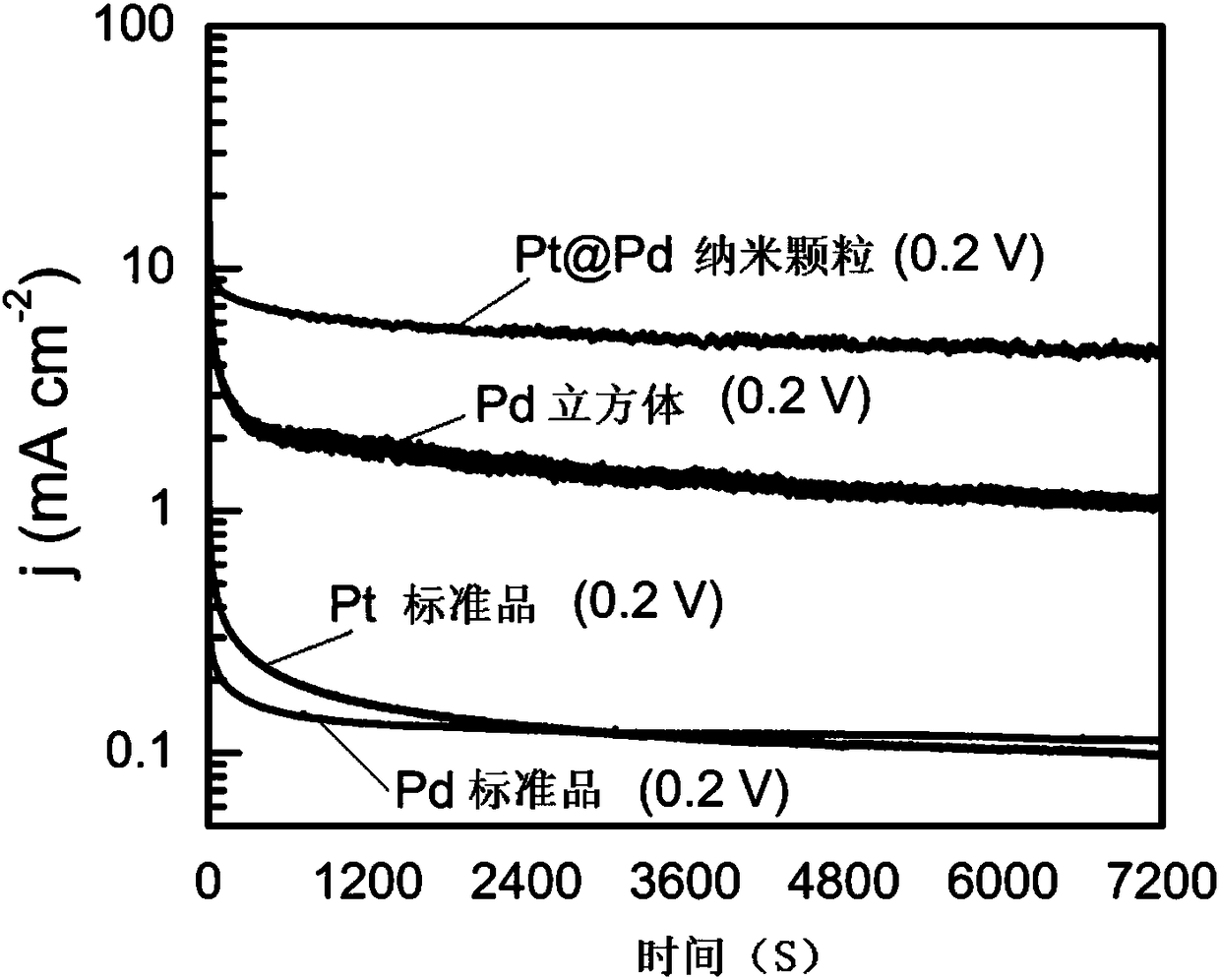

[0027] (2) Preparation of Pt@Pd nanoparticles: Weigh 1.0 mmol of cetyltrimethylammonium bromide and 0.01 mmol of potassium iodide dissolved in 40 ml of deionized water, and preheat at 50° C. for 5 min. Add 0.2ml of palladium seed solution to the above solution, stir for 10min, then add 0.2ml of H 2 PtCl 6 solution, stirred for 10 min. Finally, 0.02 mmol of ascorbic acid was added, stirred and reacted in a 50° C. constant temperature water bath for 1 h, and the solution was cooled to room temperature after the reaction was completed. The product obtained after the reaction was centrifuged, washed with deionized w...

Embodiment 2

[0029] (1) Preparation of Pd seeds: Weigh 0.2mmol cetyltrimethylammonium bromide and dissolve it in an appropriate amount of water, then add 0.03mmolH 2 PdCl 4 , so that the total volume of the solution is 20ml. Preheat in a water bath at 70°C for 10 minutes. Add 0.02mmol ascorbic acid to the flask, and magnetically stir for 2h to obtain a Pd seed solution.

[0030] (2) Preparation of Pt@Pd nanoparticles: Weigh 2 mmol of cetyltrimethylammonium bromide and 0.02 mmol of potassium iodide in 40 ml of deionized water, and preheat at 70° C. for 5 min. Add 0.2ml of palladium seed solution to the above solution, stir for 10min, then add 0.3ml of H 2 PtCl 6 solution, stirred for 10 min. Finally, 0.04 mmol of ascorbic acid was added, stirred and reacted in a 70° C. constant temperature water bath for 3 h, and the solution was cooled to room temperature after the reaction was completed. The product obtained after the reaction was centrifuged, washed with deionized water repeatedly ...

Embodiment 3

[0032] (1) Preparation of Pd seeds: Weigh 0.3mmol cetyltrimethylammonium bromide and dissolve it in an appropriate amount of water, then add 0.02mmolH 2 PdCl 4 , so that the total volume of the solution is 20ml. Preheat in a water bath at 70°C for 20 minutes. Add 0.05mmol ascorbic acid to the flask, and magnetically stir for 2h to obtain a Pd seed solution.

[0033] (2) Preparation of Pt@Pd nanoparticles: Weigh 3mmol cetyltrimethylammonium bromide, dissolve 0.04 potassium iodide in 40ml deionized water, and preheat at 70°C for 5min. Add 0.45ml of palladium seed solution to the above solution, stir for 10min, then add 0.6ml of H 2 PtCl 6 solution, stirred for 10 min. Finally, 0.04 mmol of ascorbic acid was added, stirred and reacted in a constant temperature water bath at 80° C. for 4 h, and the solution was cooled to room temperature after the reaction was completed. The product obtained after the reaction was centrifuged, washed with deionized water repeatedly for 3 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com