Intake muffler and vehicle having same

A technology of intake muffler and air filter, which is applied in the direction of intake muffler, machine/engine, combustion air/combustion-air treatment, etc., which can solve the unfavorable integration and light weight of the whole vehicle, and affect the NVH performance of the vehicle , Increase the cost of manual assembly and other issues, to achieve the effect of reducing the cost of manual assembly, improving the effect of gas noise reduction, facilitating assembly and integrated layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

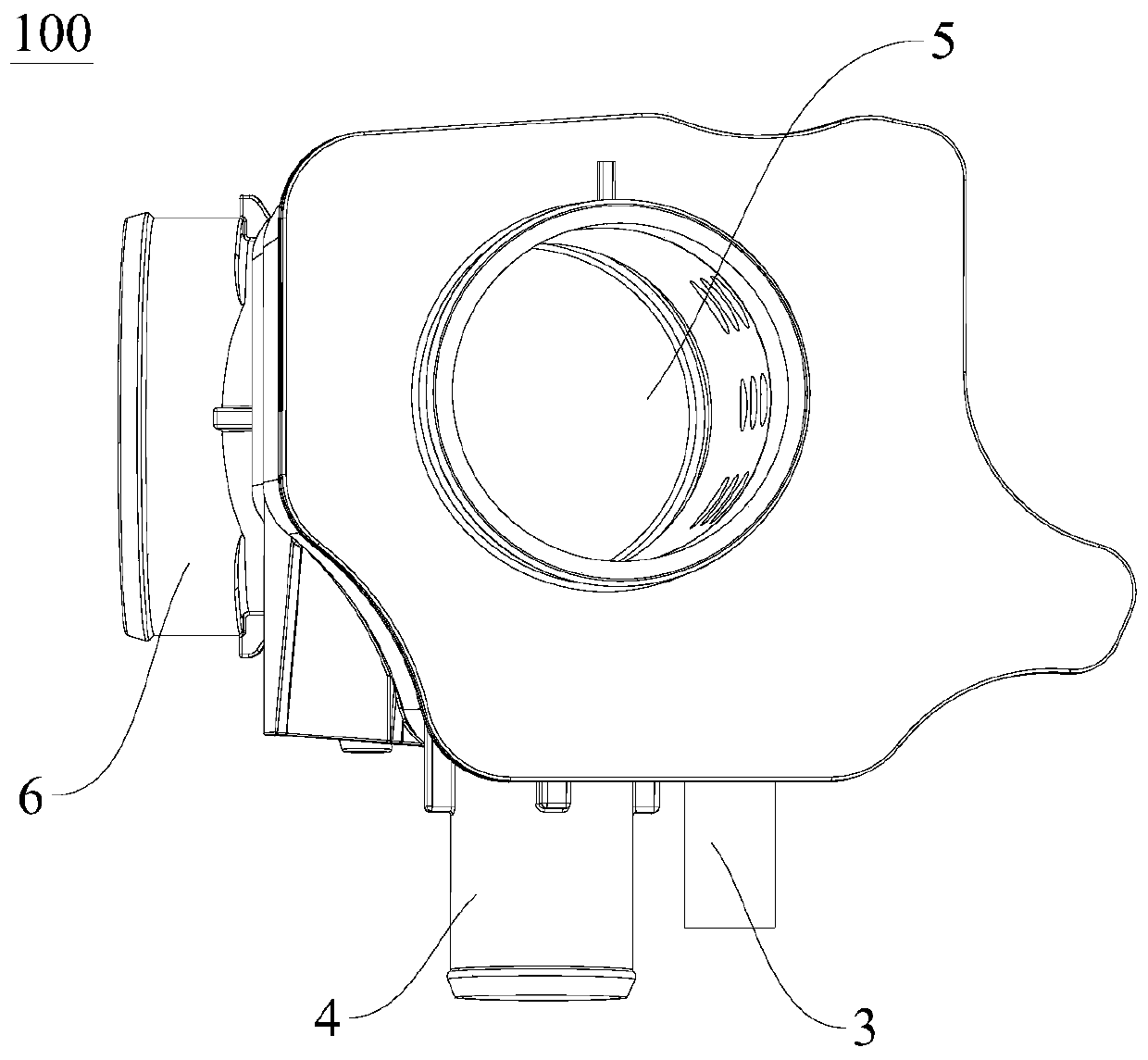

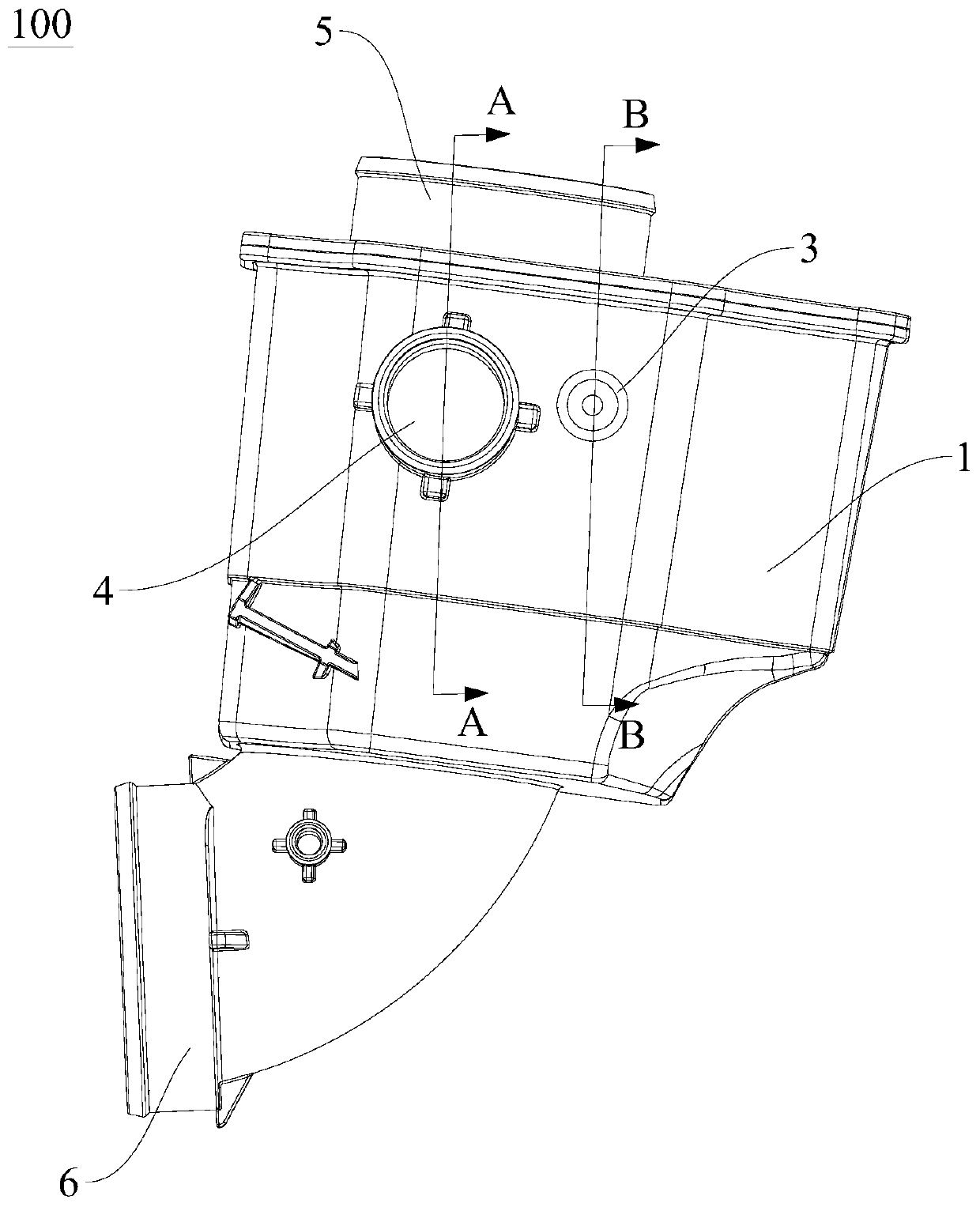

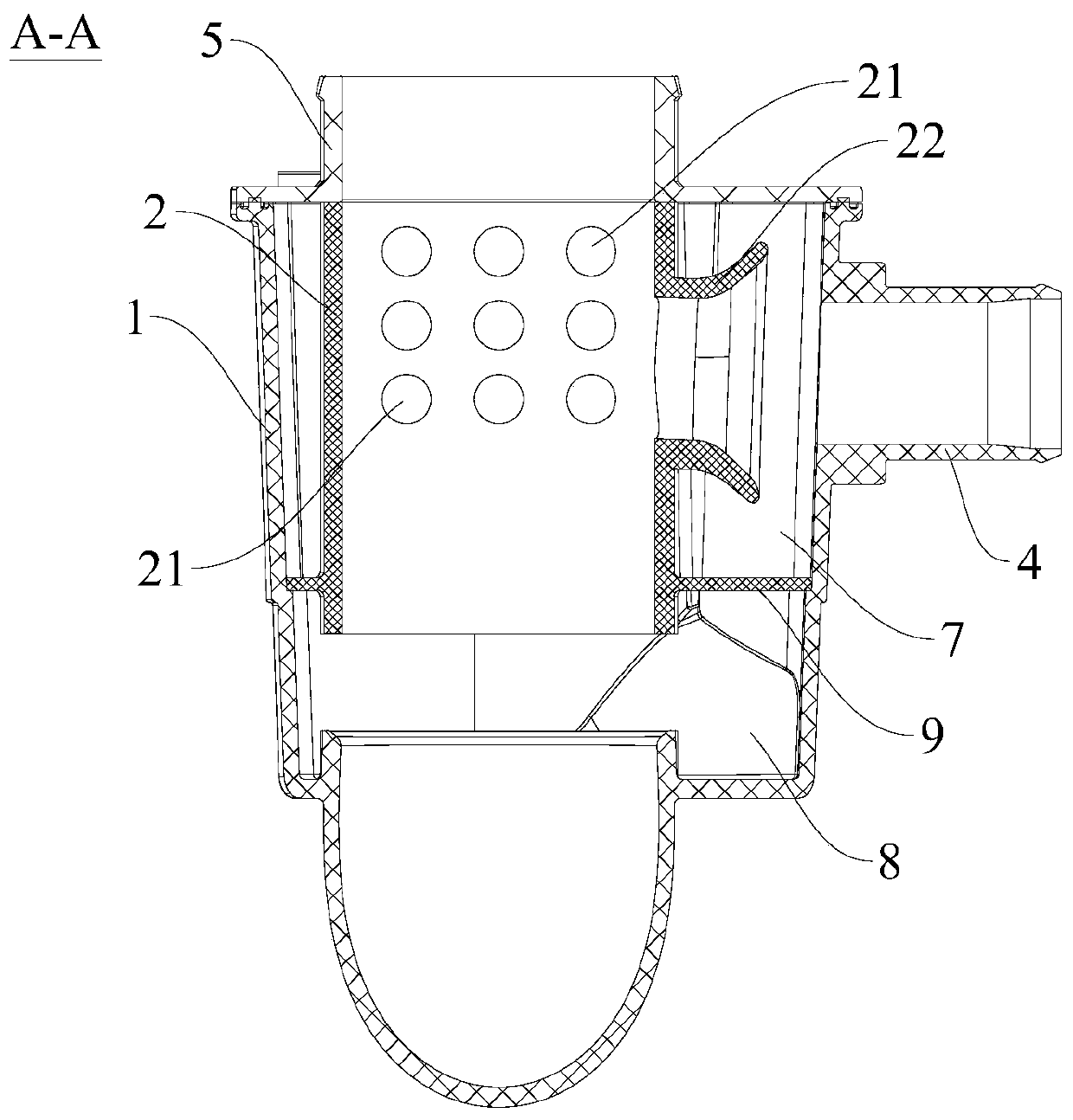

[0030] Refer below Figure 1-Figure 4 The intake muffler 100 of the embodiment of the present invention will be described in combination with the embodiments.

[0031] Such as Figure 1-Figure 4 As shown, the intake muffler 100 of the embodiment of the present invention may include an outer shell 1 , an inner shell 2 , a crankshaft ventilation port 3 , a blower pipe port 4 , an air filter port 5 and a supercharger port 6 .

[0032] Such as image 3 and Figure 4 As shown, the inner shell 2 can be arranged in the outer shell 1, and a muffler chamber 7 can be defined between the outer shell 1 and the inner shell 2, and a plurality of inner shell through holes 21 can be arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com