Waterborne environment-friendly conductive slurry and preparation method thereof

A conductive paste, environmentally friendly technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of poor discharge performance, unstable paste, difficult dispersion of nano-materials, etc., to improve dispersibility and stability, improve Low-temperature discharge performance and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a water-based environmentally friendly conductive paste, which comprises the following components:

[0036] In parts by mass, 5 parts of water-based binder, 0.1 part of carboxymethyl cellulose, 0.5 part of carbon nanotube, 0.1 part of dispersing aid, and 94.3 parts of solvent.

[0037] In this embodiment, the water-based binder is LA133.

[0038] In the present embodiment, described sodium carboxymethylcellulose is CMC2200.

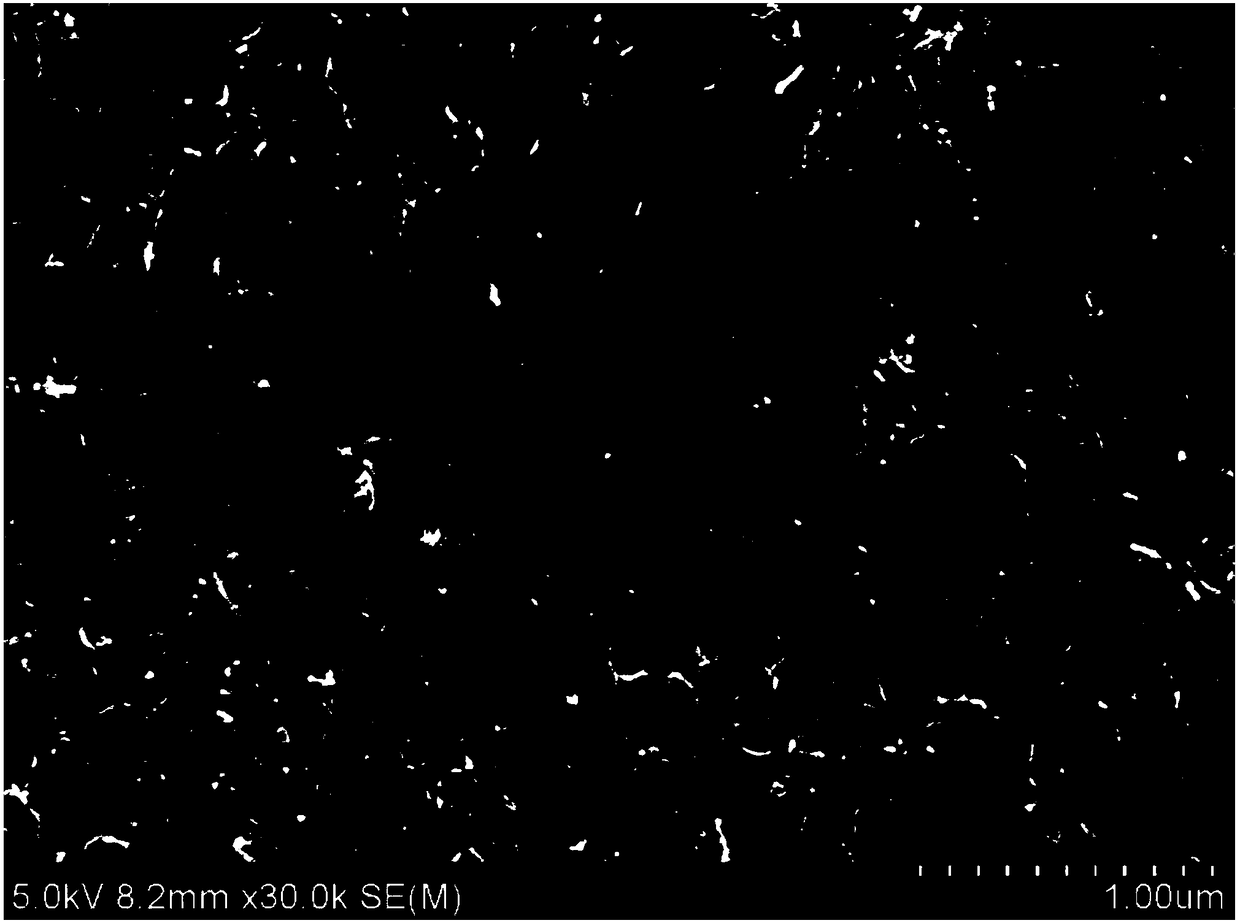

[0039] In this embodiment, the carbon nanotubes are single-walled tubes.

[0040] In this embodiment, the dispersing aid is TNWDIS.

[0041] In this embodiment, the solvent is deionized water; the solid content of the water-based environmentally friendly conductive paste is 5.7%.

[0042] A preparation method of water-based environmentally friendly conductive paste, comprising the following steps,

[0043] S1. Weigh the water-based binder, carboxymethyl cellulose, carbon nanotubes, dispersing aid, and solvent according to...

Embodiment 2

[0053] The invention provides a water-based environmentally friendly conductive paste, which comprises the following components:

[0054] In parts by mass, 15 parts of water-based binder, 2 parts of carboxymethyl cellulose, 2 parts of carbon nanotubes, 1 part of dispersing aid, and 80 parts of solvent.

[0055] In this embodiment, the water-based binder is LA133N.

[0056] In the present embodiment, the sodium carboxymethylcellulose is CRT30000PA.

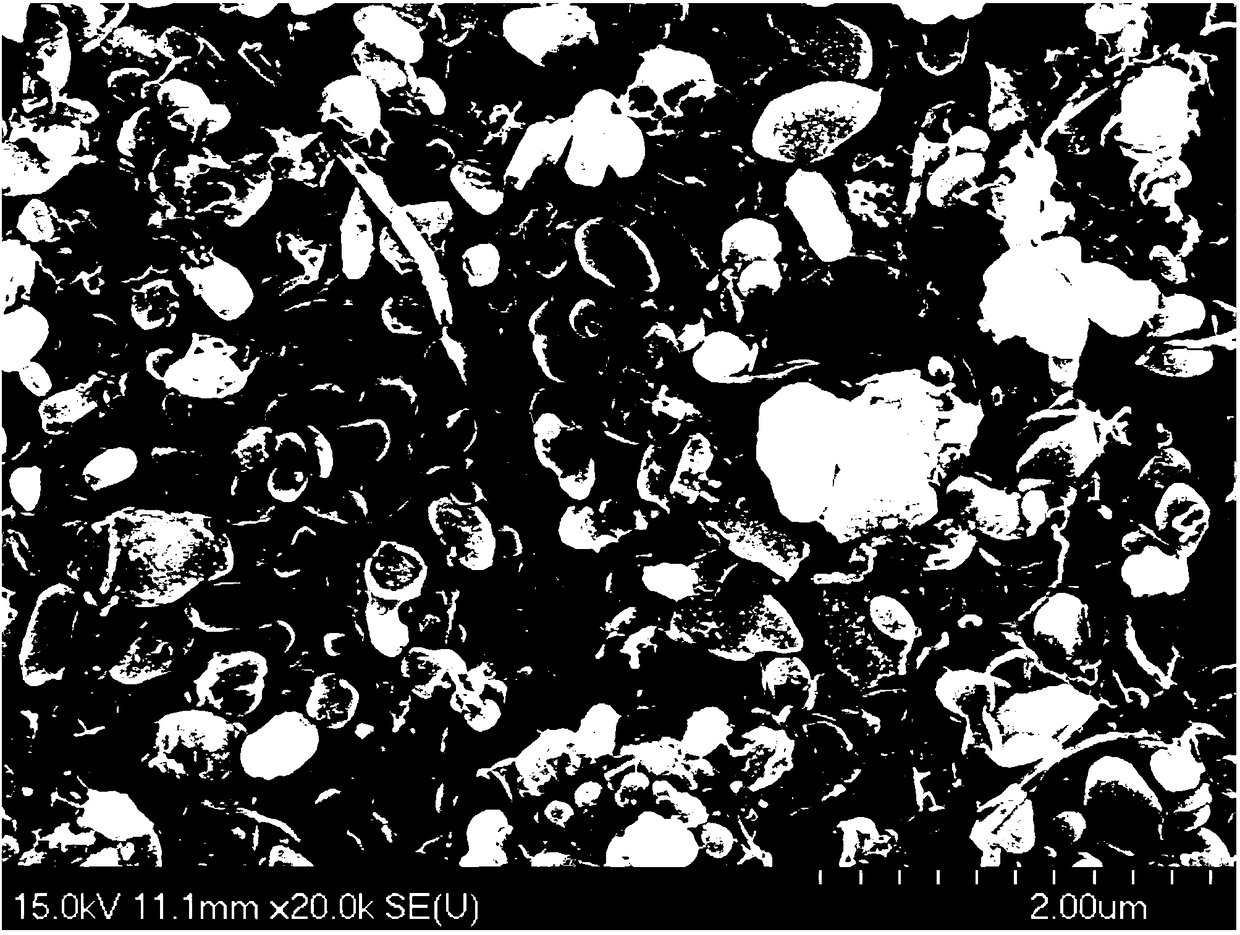

[0057] In this embodiment, the carbon nanotubes are multi-walled tubes, the diameter of the multi-walled tubes is 10 μm, and the tube length is 12 μm.

[0058] In this embodiment, the dispersing aid is an aromatic ring dispersing aid with a hydrophilic group.

[0059]本实施例中,所述的溶剂为双蒸水;水性环保导电浆料的固含量为20%。

[0060] 一种水性环保导电浆料的制备方法,包括以下步骤,

[0061] S1、按质量比称取所述的水性粘结剂、羧甲基纤维素、碳纳米管、分散助剂、溶剂;

[0062] S2、将称量好的物料按溶剂、分散助剂、碳纳米管的顺序添加到搅拌机内,预分散后形成固 / 液 / 气三相共存的混合物;

[0063] S3、将S2得到的混合物用隔膜泵转移到砂磨机中进行磨砂处理;

[0064] S4、将S3得到的混合物用隔膜泵过滤至搅拌机中,加入S1中准备好的羧...

Embodiment 3

[0071] 本发明提供一种水性环保导电浆料,包括以下组分:

[0072] 按质量份计,水性粘结剂7份、羧甲基纤维素1份、碳纳米管5份、分散助剂2份、溶剂85份。

[0073] 本实施例中,所述的水性粘结剂为LA133N和LA132。

[0074] 本实施例中,所述的羧甲基纤维素钠为CRT30000PA和CRT10000PA。

[0075] 本实施例中,所述的碳纳米管为多壁管,多壁管的管径为3μm,管长为8μm。

[0076] 本实施例中,所述的分散助剂为带亲水基团的芳香环类分散助剂。

[0077] 本实施例中,所述的溶剂为双蒸水;水性环保导电浆料的固含量为15%。

[0078] 一种水性环保导电浆料的制备方法,包括以下步骤,

[0079] S1、按质量比称取所述的水性粘结剂、羧甲基纤维素、碳纳米管、分散助剂、溶剂;

[0080] S2、将称量好的物料按溶剂、分散助剂、碳纳米管的顺序添加到搅拌机内,预分散后形成固 / 液 / 气三相共存的混合物;

[0081] S3、将S2得到的混合物用隔膜泵转移到砂磨机中进行磨砂处理;

[0082] S4、将S3得到的混合物用隔膜泵过滤至搅拌机中,加入S1中准备好的羧甲基纤维素,进行高速分散;过滤,过滤筛网采用250目的锲形筛网;

[0083] S5、加入S1中准备好的水性粘结剂,重复步骤S4,抽真空消泡,得到水性环保导电浆料。

[0084] 本实施例中,步骤S2中,搅拌机采用超声波分散搅拌机,将溶剂温度控制在35℃;搅拌机的公转速度为19RPM、自转线速度为9m / s,预分散时间为20min;

[0085] 步骤S3中,砂磨介质选用1.1mm的硅酸锆珠或氧化锆珠,磨砂处理时间为17min;

[0086] 步骤S4中,搅拌机采用双行星搅拌机;高速分散的时间为40min;

[0087] 步骤S3和步骤S4中,隔膜泵采用Husky3300隔膜泵。

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com