Cheese sauce seasoning and preparation method thereof

A seasoning and cheese sauce technology, which is applied in the field of cheese sauce seasoning and its preparation, can solve the problems of time-consuming, difficult to ensure consistent product taste and flavor, and difficult production process, so as to reduce greasy feeling, adsorption and embedding Obvious and streamlined preparation process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

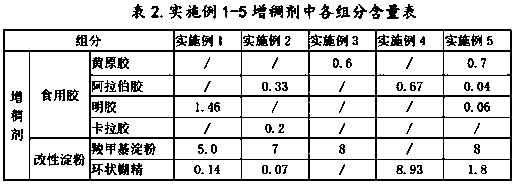

[0056] A kind of cheese sauce seasoning, by weight, the content of each component is as shown in the table below:

[0057]

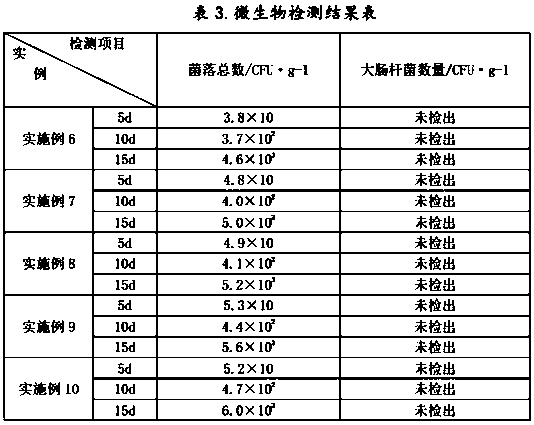

[0058] In each of the above embodiments, the thickener contains at least one edible gum and at least one modified starch. The composition of thickener in each embodiment is shown in the table below in parts by weight:

[0059]

[0060] The enzymolyzed butter used in the examples is obtained from anhydrous butter through lipase enzymolysis, and the lipase used is Novozymes 435 purchased from Novozymes, and the weight ratio of lipase used for enzymolysis to anhydrous butter is 0.0006 :6.

[0061] Potassium sorbate used as a preservative in the examples can also be replaced with sodium sorbate or benzoic acid.

[0062] Edible gum, modified starch, non-dairy creamer, edible essence, starch octenyl succinate, and aspartame used in the examples are all food grade, and the dosage complies with GB2760-2014 "National Food Safety Standard Food Additive Use...

Embodiment 6

[0064] A preparation method of cheese sauce seasoning, it comprises the steps:

[0065]Step 1. Butter enzymatic hydrolysis: mix butter and water in a weight ratio of 1:1, and stir at a speed of 200r / min. After heating up to 60°C, lipase Novozymes 435 was added, and the weight ratio of added lipase to butter was controlled to be 0.0006:6. After 2 hours of heat preservation reaction, the reaction was terminated, and the temperature was raised to 85° C. for 30 minutes to inactivate the lipase in the material. Let it stand for stratification, and take the upper layer of butter enzymatic hydrolyzate for later use.

[0066] Material preparation: Weigh 145 parts of water according to the weight and pour it into the blender, add 4 parts of enzymatically treated butter, 3 parts of sodium starch octenyl succinate, 1.46 parts of gelatin, 5 parts of carboxymethyl starch, and ring paste into the water 0.14 parts of essence, 90 parts of maltodextrin, 130 parts of white granulated sugar, 2...

Embodiment 7

[0071] A preparation method of cheese sauce seasoning, it comprises the steps:

[0072] Step 1. Material preparation: Weigh 150 parts of water according to the weight and pour it into the mixer, add 5 parts of butter without enzymatic treatment, 4 parts of sodium starch octenyl succinate, 0.33 parts of gum arabic, 0.2 parts of carrageenan, 7 parts of carboxymethyl starch, 0.07 parts of cyclodextrin, 95 parts of maltodextrin, 135 parts of white sugar, 2.7 parts of salt, 8.5 parts of monosodium glutamate, 11 parts of cheese powder, 90 parts of milk and 0.25 parts of disodium nucleotide part, stir and mix evenly to obtain a mixed material.

[0073] Step 2, gelatinization: Stir the mixed material in step 1 at a speed of 135 r / min, heat to 100° C., and keep warm for 10-20 minutes to obtain a gelatinized material.

[0074] Step 3. Homogenization: After the gelatinized material obtained in Step 2 is cooled to 60°C, add 0.35 parts of aspartame, 9 parts of cheese essence, 5 parts of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com