Purification technology of attapulgite clay

An attapulgite clay and process technology, applied in inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve problems such as adverse effects of adsorption performance and colloidal performance, achieve retention of high adsorption performance and colloidal performance, improve colloidal performance and Adsorption performance, effect of retaining particle dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

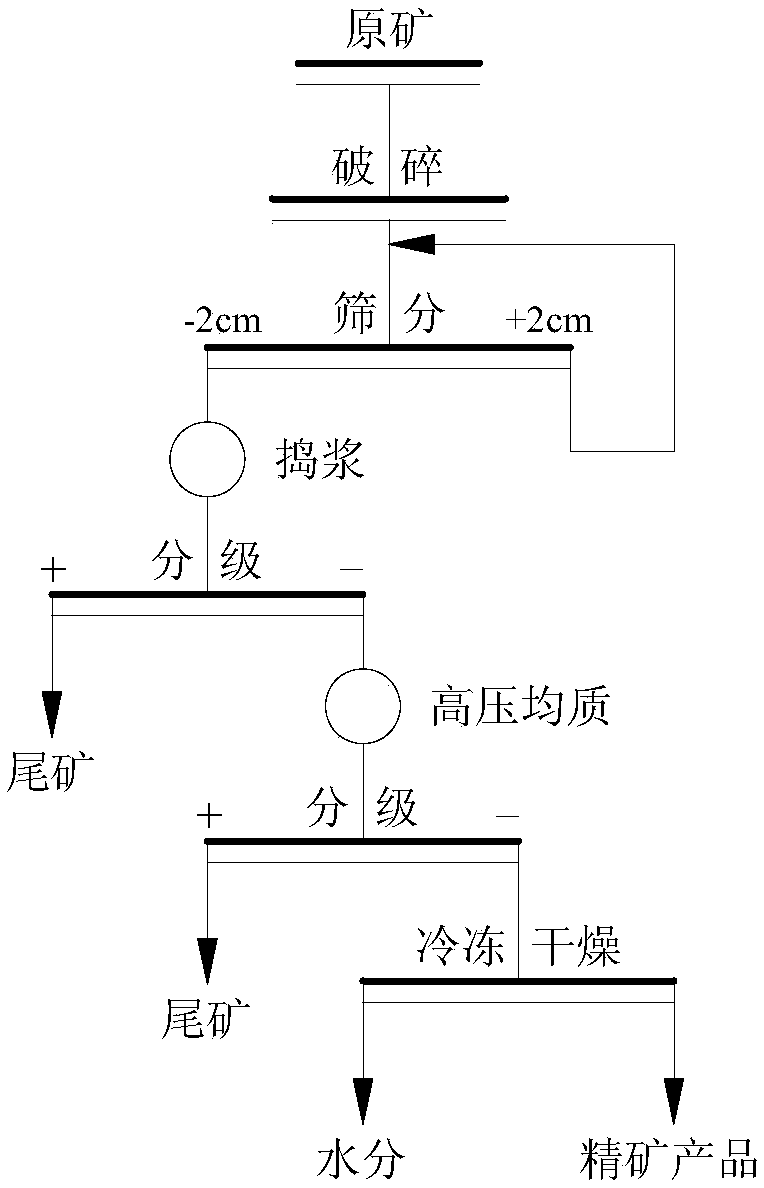

[0046] The purification process of the attapulgite clay of the present embodiment comprises the steps:

[0047] (1) crushing the low-grade attapulgite clay raw ore with a grade of 35% to below 2 cm;

[0048] (2) After adding an appropriate amount of water to the crushed product, mash, the mashing concentration is 15%, and the mashing time is 30 minutes;

[0049] (3) The product after mashing is sieved, and the sieving particle size is 45 μm, and the coarse particles are directly thrown to the tail;

[0050] (4) Utilize a high-pressure homogenizer to carry out high-pressure high-shear dispersion to the classified fine particles, and the pressure is 200MPa;

[0051] (5) The dispersed product is subjected to classification and purification, and the classification particle size is 3 μm;

[0052] (6) Use a vacuum freeze dryer to freeze-dry the fine-grained products after classification, the freezing temperature <-30°C, and the vacuum degree <20Pa to obtain a concentrate product w...

Embodiment 2

[0055] The purification process of the attapulgite clay of the present embodiment comprises the steps:

[0056] (1) crushing the low-grade attapulgite clay raw ore with a grade of 30% to below 2 cm;

[0057] (2) After adding an appropriate amount of water to the crushed product, mash, the mashing concentration is 20%, and the mashing time is 20 minutes;

[0058] (3) The product after mashing is sieved, and the sieving particle size is 74 μm, and the coarse particles are directly thrown to the tail;

[0059] (4) Utilize a high-pressure homogenizer to carry out high-pressure high-shear dispersion to the classified fine particles, and the pressure is 300MPa;

[0060] (5) The dispersed product is subjected to classification and purification, and the classification particle size is 2 μm;

[0061] (6) Use a vacuum freeze dryer to freeze-dry the fine-grained products after classification, the freezing temperature <-30 ° C, and the vacuum degree < 20 Pa to obtain a concentrate produ...

Embodiment 3

[0064] The purification process of the attapulgite clay of the present embodiment comprises the steps:

[0065] (1) crushing the low-grade attapulgite clay ore with a grade of 27% to below 2 cm;

[0066] (2) After adding an appropriate amount of water to the crushed product, mash it, the mashing concentration is 30%, and the mashing time is 30 minutes;

[0067] (3) The product after mashing is sieved, and the sieving particle size is 74 μm, and the coarse particles are directly thrown to the tail;

[0068] (4) Utilize a high-pressure homogenizer to carry out high-pressure high-shear dispersion to the classified fine particles, and the pressure is 200MPa;

[0069] (5) Carrying out classification and purification to the dispersed product, the classification particle size is 1 μm;

[0070] (6) Use a vacuum freeze dryer to freeze-dry the fine-grained product after classification, the freezing temperature <-30 ° C, and the vacuum degree < 20 Pa to obtain a concentrate product wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com