A kind of inorganic fireproof air duct board and its preparation method and application

A fire-proof and inorganic technology, applied in the direction of mechanical equipment, pipeline protection, pipeline damage/wear prevention, etc., can solve the problems of fire prevention and ecological performance of the board, and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of an inorganic fireproof air duct plate, comprising the steps of:

[0031] S1. Powder pre-mixing and glue pre-preparation: Prepare two sets of gelling powder for backup, and pre-preparate the same number of compound glue for use;

[0032] The first group of gelling powder: 12 parts of calcium sulfate hemihydrate, 4 parts of calcium silicate, 4 parts of shell powder, 8 parts of diatom concentrate, 72 parts of lightly burned magnesium oxide;

[0033] The second group of gelling powder: 8 parts of calcium sulfate hemihydrate, 12 parts of shell powder, 8 parts of diatomite, 72 parts of lightly burned magnesium oxide;

[0034] The first group of compound glue: consists of 80 parts of 24wt% magnesium sulfate, 2 parts of modifier, 0.8 part of waterproofing agent and 0.2 part of defoamer, wherein the modifier consists of 0.5 part of citric acid and 0.5 part of hexametaphosphoric acid Sodium, 0.5 parts of aluminum sulfate octadecahydrate and 0.5 parts of p...

Embodiment 2

[0041] A preparation method of an inorganic fireproof air duct plate, comprising the steps of:

[0042] S1. Powder pre-mixing and glue pre-preparation: Prepare three sets of gelling powder for backup, and pre-preparate the same number of compound glue for use;

[0043] The first group of gelling powder: 12 parts of calcium sulfate hemihydrate, 4 parts of calcium silicate, 4 parts of shell powder, 8 parts of diatom concentrate, 72 parts of lightly burned magnesium oxide;

[0044] The second group of gelling powder: 8 parts of calcium sulfate hemihydrate, 12 parts of shell powder, 8 parts of diatomite, 72 parts of lightly burned magnesium oxide;

[0045] The third group of gelling powder: 12 parts of calcium sulfate hemihydrate, 4 parts of calcium silicate, 4 parts of shell powder, 8 parts of diatom concentrate, 72 parts of lightly burned magnesium oxide;

[0046] The first group of compound glue: consists of 100 parts of 18wt% magnesium sulfate, 2 parts of modifier, 0.8 part o...

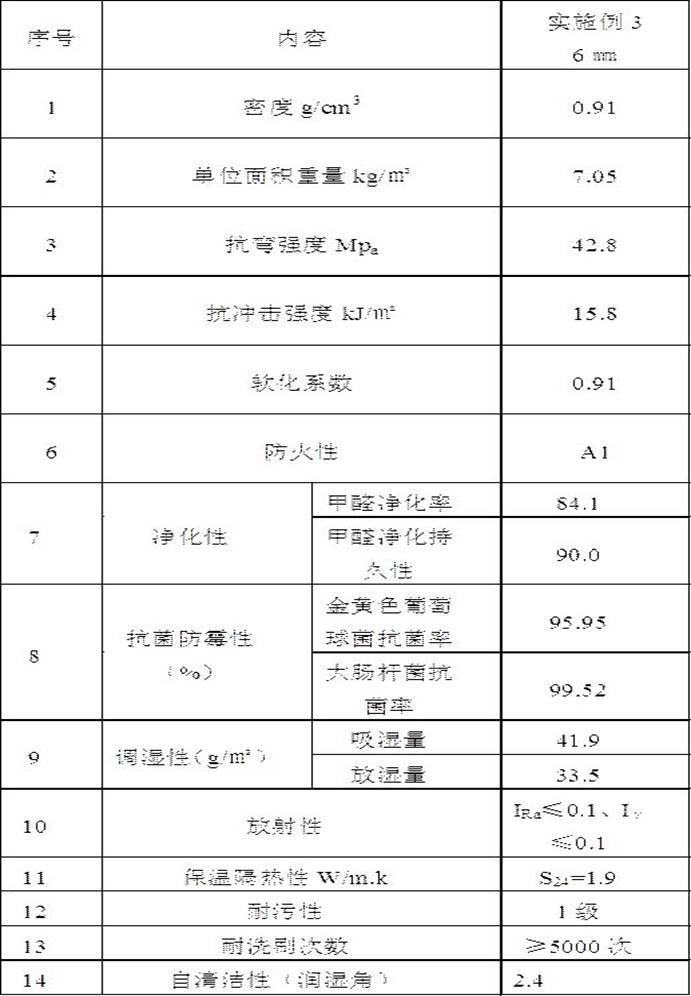

Embodiment 3

[0054] A preparation method of an inorganic fireproof air duct plate, comprising the steps of:

[0055] S1. Powder pre-mixing and glue pre-preparation: Prepare two sets of gelling powder for backup, and pre-preparate the same number of compound glue for use;

[0056] The first group of gelling powder: 12 parts of calcium sulfate hemihydrate, 4 parts of calcium silicate, 4 parts of shell powder, 8 parts of diatom concentrate, 72 parts of lightly burned magnesium oxide;

[0057] The second group of gelling powder: 8 parts of calcium sulfate hemihydrate, 12 parts of shell powder, 8 parts of diatomite, 72 parts of lightly burned magnesium oxide;

[0058] The first group of compound glue: consists of 83 parts of 21wt% magnesium sulfate, 2 parts of modifier, 0.8 part of waterproofing agent and 0.2 part of defoamer, wherein the modifier consists of 0.5 part of citric acid and 0.5 part of hexametaphosphoric acid Sodium, 0.5 parts of aluminum sulfate octadecahydrate and 0.5 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com