Benzocyclobutene functionalized tetrakis(dimethylsiloxy)silane, preparation method thereof, and preparation method of resin containing benzocyclobutene functionalized tetrakis(dimethylsiloxy)silane

A benzocyclobutene-functional, dimethylsiloxy technology, applied in chemical instruments and methods, organic chemistry, silicon organic compounds, etc., can solve problems such as poor film-forming performance, difficult processing, and low dielectric properties , to achieve the effect of low dielectric properties, easy operation, high thermal stability and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

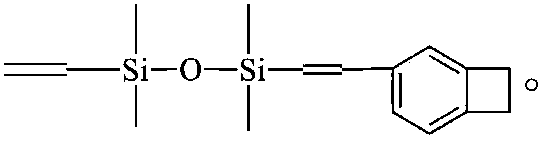

[0027] Another aspect of the present invention provides a method for preparing benzocyclobutene functionalized tetrakis(dimethylsiloxy)silane. In an exemplary embodiment of the preparation method of benzocyclobutene-functionalized tetrakis(dimethylsiloxy)silane of the present invention, the preparation method includes:

[0028] Step S01, preparing a solution containing a catalyst.

[0029] In this example, the catalyst may be a platinum catalyst, and preferably, the catalyst may be chloroplatinic acid. Of course, the catalyst of the present invention is not limited to this, as long as it can promote the reaction of the present invention.

[0030] In this example, in the solution containing the catalyst, in order to make the reaction more fully and without wasting raw materials, the concentration of the catalyst may be 0.020 mol / L to 0.030 mol / L. Preferably, it can be 0.022 mol / L to 0.028 mol / L, more preferably, it can be 0.025 mol / L. The solution of the catalyst may be a tetrahydr...

example 1

[0062] Method for preparing benzocyclobutene functionalized tetrakis(dimethylsiloxy)silane. The preparation method may include the following steps:

[0063] In a dry anaerobic flask equipped with a magnetic stirrer, add tetrakis(dimethylsiloxy)silane (TMSS) (2.85g, 8.66mmol), 15mL dry toluene, monosubstituted tetramethyldivinyl Siloxybenzocyclobutene (10.24g, 35.51mmol), 0.025mol / L chloroplatinic acid in tetrahydrofuran solution 300μL. The reaction was continued for 48 hours at a reaction temperature of 75°C and strong stirring to obtain the first material after the reaction. The first material after the reaction was cooled to room temperature and filtered through silica gel (to remove the catalyst in the crude product) to obtain a colorless solution. After removing the toluene from the colorless solution at the temperature of a rotary evaporator (evaporate until no toluene is distilled out), a light yellow liquid is obtained. After the liquid was subjected to silica gel colum...

example 2

[0068] The preparation method of benzocyclobutene functionalized tetrakis (dimethylsiloxy) silane, the steps of the preparation method are:

[0069] In a dry anaerobic flask equipped with a magnetic stir bar, add tetrakis (dimethylsiloxy) silane (TMSS) (2.85g, 8.66mmol), 15mL dry toluene, monosubstituted tetramethyldivinyl Siloxy benzocyclobutene (10.49 g, 36.37 mmol), 0.025 mol / L chloroplatinic acid in tetrahydrofuran solution 300 μL, reacted continuously for 36 hours at a reaction temperature of 80° C. and strong stirring, to obtain the reacted material. After the reaction, the material was cooled to room temperature, filtered through silica gel (to remove the catalyst in the crude product) to obtain a colorless solution. After the colorless solution was used to remove toluene at the temperature of a rotary evaporator (evaporate until no toluene was distilled), a light yellow liquid was obtained . After the liquid was subjected to silica gel column chromatography (silica gel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com