Preparation method of efficient polycrystalline silicon ingot and efficient polycrystalline silicon ingot

A polycrystalline silicon ingot, high-efficiency technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of difficult control of the melting state of crushed silicon materials, high process difficulty, etc., to save material time and reduce process Difficulty, the effect of improving the yield rate and high efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

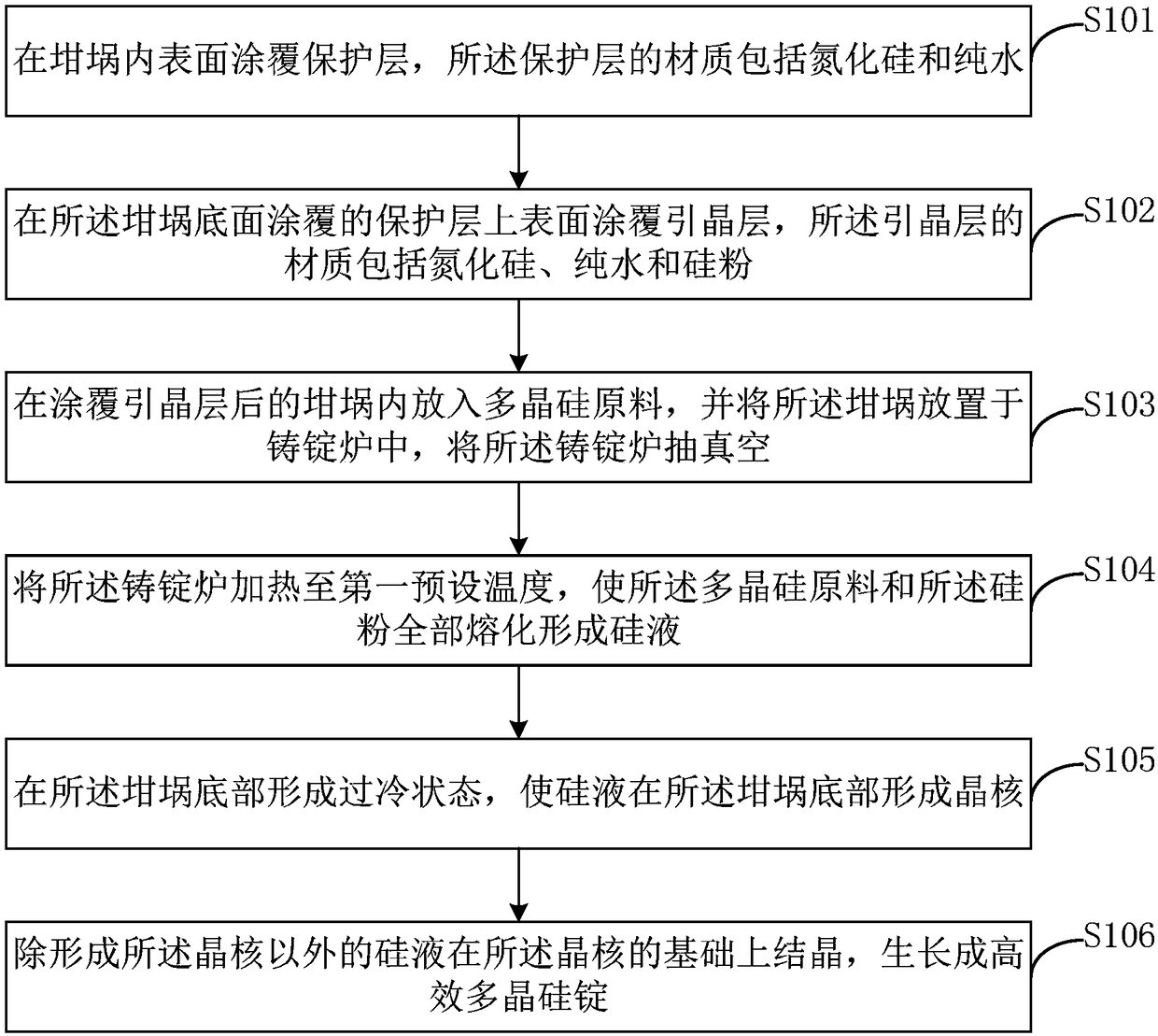

[0030] Please refer to figure 1 , the preparation method of high-efficiency polysilicon ingot includes:

[0031] In step S101, a protective layer is coated on the inner surface of the crucible, and the material of the protective layer includes silicon nitride and pure water.

[0032] In the embodiment of the present invention, the crucible is a quartz crucible, and the main material is silicon dioxide. The protective layer needs to meet the following requirements: the protective layer has sufficient compactness and has a good isolation effect on the silicon liquid and the crucible; the chemical property is stable and does not react with the crucible and the silicon liquid; it has sufficient adhesion strength on the inner surface of the crucible, Does not fall off or burst at high temperatures. In this embodiment, the material of the protective layer is a mixed solution of high-purity silicon nitride and pure water. Silicon nitride can avoid direct contact between polysilico...

Embodiment 2

[0060] A high-efficiency polycrystalline silicon ingot is prepared according to the preparation method of the high-efficiency polycrystalline silicon ingot as described in the first embodiment of the present invention, and has the beneficial effects of the first embodiment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com