PET self-adhesion polymer modified asphalt waterproof roll construction technology

A waterproofing membrane and modified bitumen technology, which is used in the processing of building materials, tools for roof engineering, building construction, etc. It is difficult to fit the color steel roof with the color steel roof, and the waterproof membrane is difficult to fit closely with the color steel roof, so as to achieve the effect of high laying efficiency, good high and low temperature performance, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment relates to a construction process of PET self-adhesive polymer modified asphalt waterproof membrane, including the following steps:

[0039] Step 1: Base surface treatment: Use tools such as shovels and scrapers to remove rust and sundries on the surface of the color steel roof to keep the color steel roof clean and free from open water. Set the reference line on the color steel roof, and apply the adhesive evenly on the color steel roof. The thickness of the adhesive is 2mm.

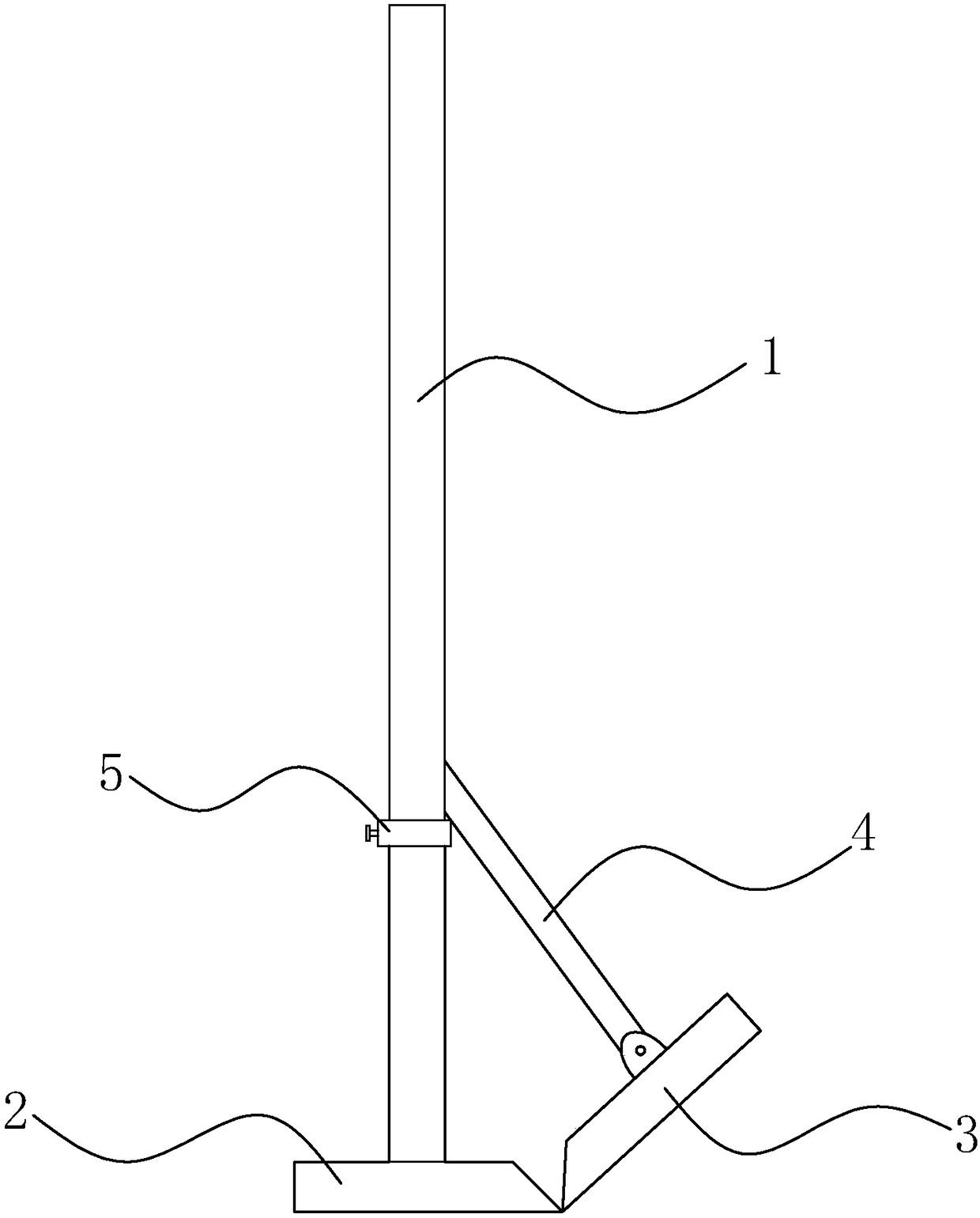

[0040] Step 2: Measure the angle between the color steel roof and the color steel tile corrugated structure to be 125°, slide the connecting rod 4 on the vertical bar 1, so that the angle between the inclined side plate 3 and the horizontal side plate 2 is 125°, move the limit block 5 to the place where it abuts against the connecting rod 4, so that the connecting rod 4 is fixed.

[0041]Step 3: Reserve an 8cm margin on the edge of the waterproof membrane, uncover the isolation f...

Embodiment 2

[0049] The difference between the present embodiment and the first embodiment mainly lies in that: 5 cm is reserved at the edge of the waterproof membrane when laying; the formulation of the waterproof membrane and the adhesive are different.

[0050] The modified asphalt layer of PET self-adhesive polymer modified asphalt waterproofing membrane is made of the following raw materials in parts by weight: 48 parts of 90# petroleum asphalt, 11 parts of SBS modifier, 4 parts of SBR modifier, and 6 parts of naphthenic oil parts, 5 parts of tackifying resin, 1.8 parts of dilauryl thiodipropionate and 25 parts of heavy calcium. The tackifying resin is composed of rosin resin and hydrogenated petroleum resin in a mass ratio of 1:4.5.

[0051] The low-temperature flexible adhesive is made of the following raw materials in parts by weight: 60 parts of 90# petroleum asphalt, 12 parts of SBS modifier, 2 parts of SBR modifier, 1 part of naphthenic oil and 18 parts of heavy calcium.

Embodiment 3

[0053] The difference between the present embodiment and the first embodiment mainly lies in that: when laying, the reserved edge of the waterproof membrane is 12 cm; the formula of the waterproof membrane and the adhesive is different.

[0054] The modified asphalt layer of PET self-adhesive polymer modified asphalt waterproofing membrane is made of the following raw materials in parts by weight: 50 parts of 90# petroleum asphalt, 12 parts of SBS modifier, 5 parts of SBR modifier, and 8 parts of naphthenic oil parts, 8 parts of tackifying resin, 3 parts of trinonylphenyl phosphite and 30 parts of heavy calcium. The tackifying resin is composed of rosin resin and hydrogenated petroleum resin in a mass ratio of 1:4.5.

[0055] The low-temperature flexible adhesive is made of the following raw materials in parts by weight: 62 parts of 90# petroleum asphalt, 12 parts of SBS modifier, 3 parts of SBR modifier, 2 parts of rubber oil and 20 parts of heavy calcium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com