Method for using microwave spraying freeze-drying to intelligently detect moisture content and texture in high-sugar fruit

An intelligent detection and fruit technology, applied in measuring devices, analyzing materials, measuring magnetic variables, etc., can solve problems such as complex fruit detection technology, and achieve the effects of improving detection work efficiency and product integrity, short time consumption, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Intelligent detection of moisture content and texture of apple grains during negative pressure and low frequency microwave spray freeze-drying

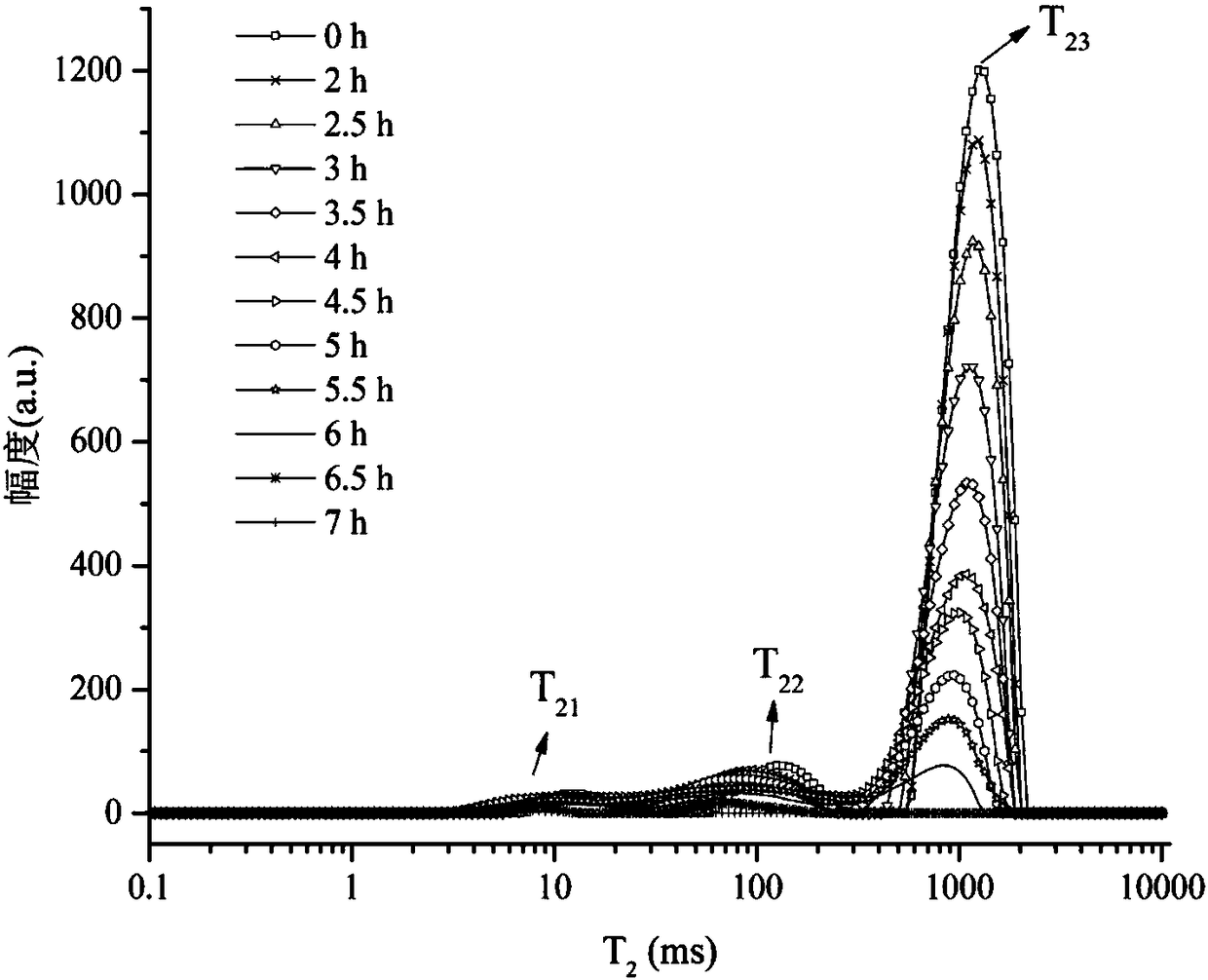

[0035] After the apples are cleaned with water, peeled and cored, cut into cubes of 10×10×10mm; the apples are evenly placed on a tray made of stainless steel mesh, and placed in a quick-freezer at -67°C for freezing , freezing time 2h; pour the frozen apples into the drying bin at -42°C, turn on the vacuum pump, and when the vacuum reaches 70Pa, start the heating system (low-frequency microwave, 915MHz) to enter the freeze-drying stage, and pulse spraying during this process The working setting of the system is: open for 0.4s, close for 10min; in the process of negative pressure low frequency microwave spray freeze-drying, staged sampling for low-field nuclear magnetic resonance analysis, to obtain the transverse relaxation time T of the sample 2 curve (eg figure 1 ) and each response signal parameter, the peaks app...

Embodiment 2

[0041] Example 2 Intelligent detection of dry moisture content and texture of pears during negative pressure low frequency microwave spray freeze-drying process

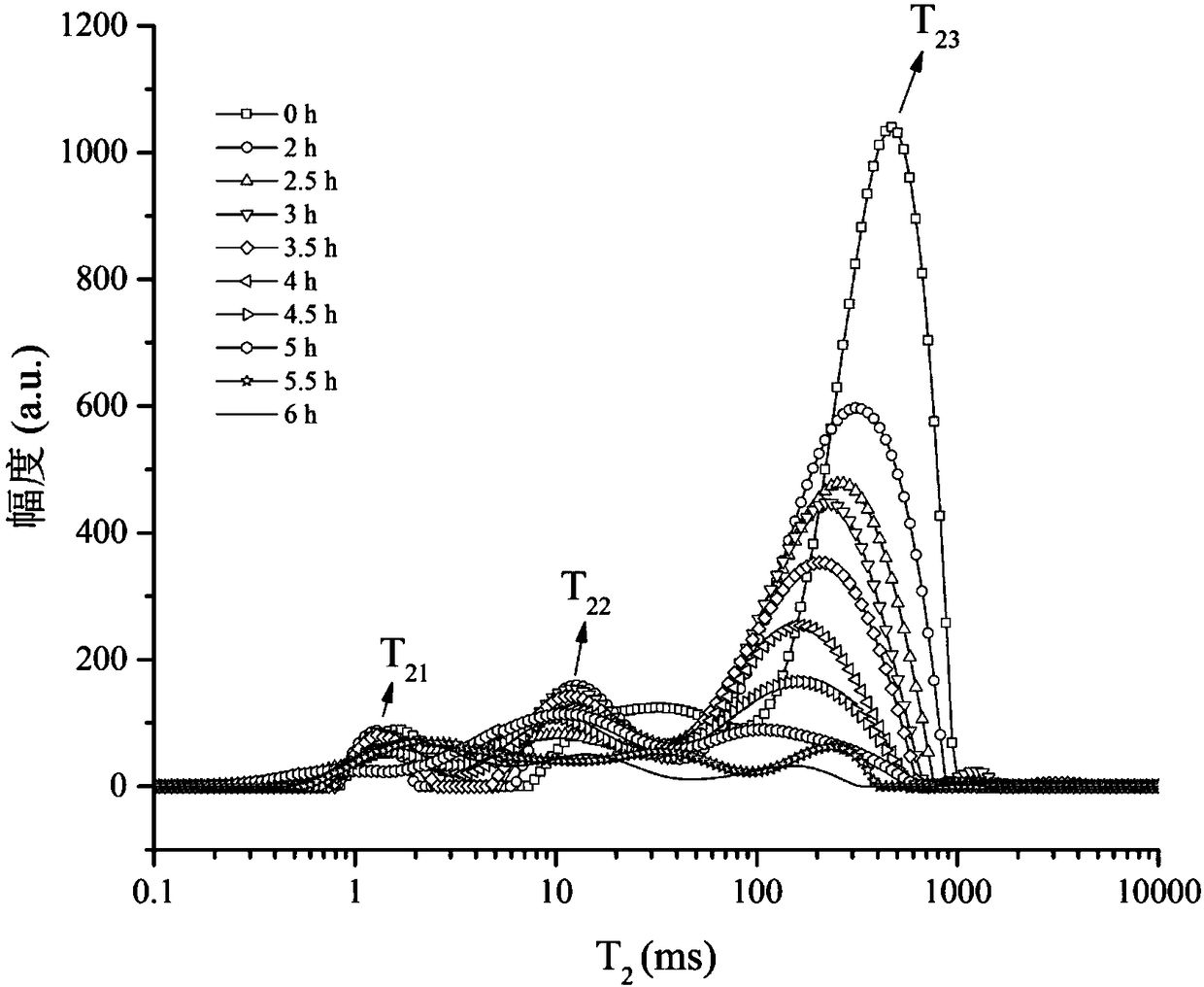

[0042] After cleaning the pears with clean water, peel and core, cut into cubes of 10×10×10mm; spread the pears evenly on a tray made of stainless steel mesh, and place them in a quick-freezing warehouse at -67°C. Freezing, freezing time 2h; pour the frozen pears into the drying chamber at -42°C, turn on the vacuum pump, and when the vacuum reaches 70Pa, start the heating system (low frequency microwave, 915MHz) to enter the freeze-drying stage, and pulse spraying during this process The working setting of the system is: open for 0.4s, close for 10min; in the process of negative pressure low frequency microwave spray freeze-drying, staged sampling for low-field nuclear magnetic resonance analysis, to obtain the transverse relaxation time T of the sample 2 curve (eg figure 2 ) and each response signal parameter, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com