Preparation and application of CdS/MoS2/C60C(COOH)2 ternary composite

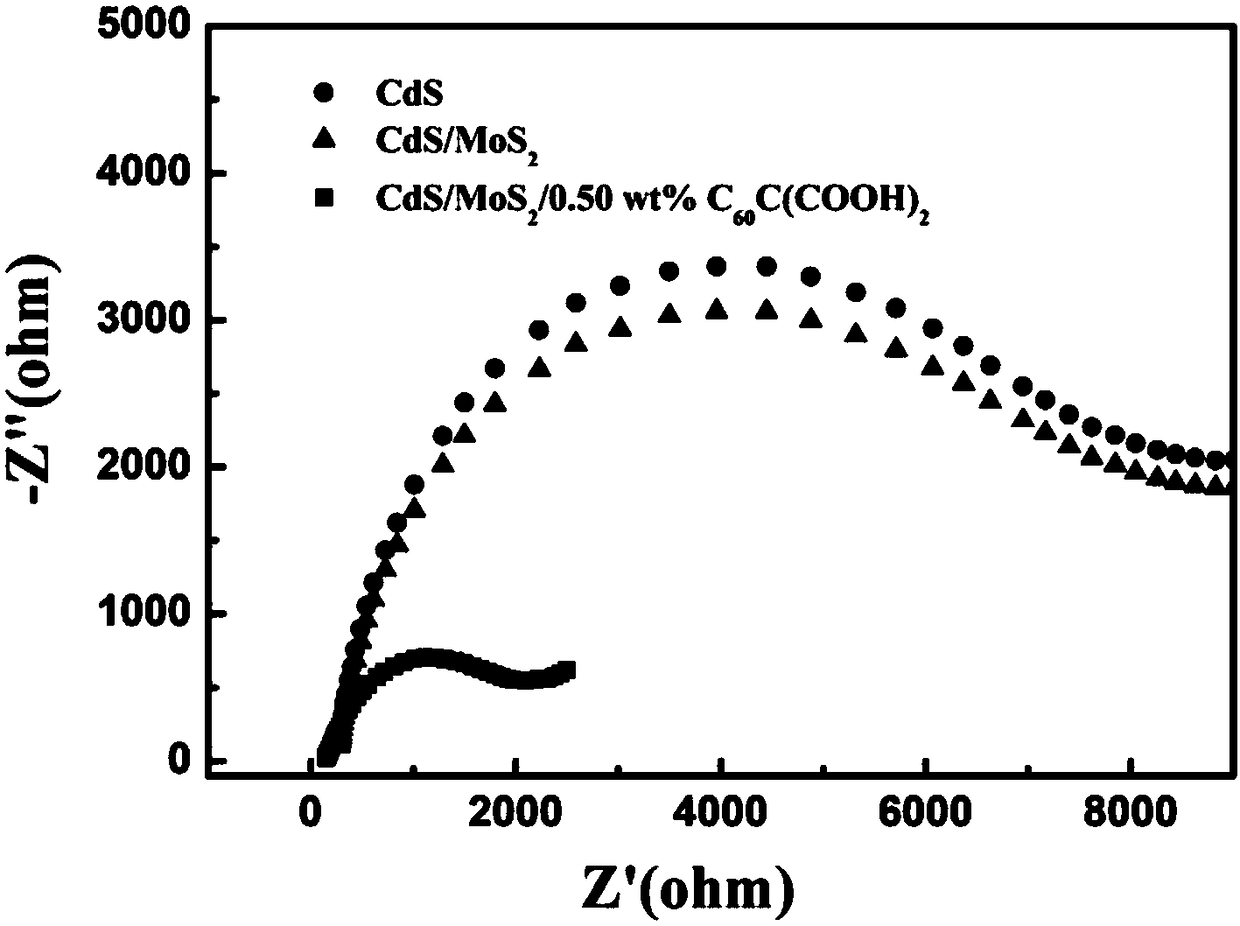

A technology of composite materials and nanomaterials, which is applied in the field of simple preparation of CdS/MoS2/C60C2 composite materials, can solve problems such as photocorrosion, achieve the effects of less consumption, mild reaction conditions, and weaken photocorrosion phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

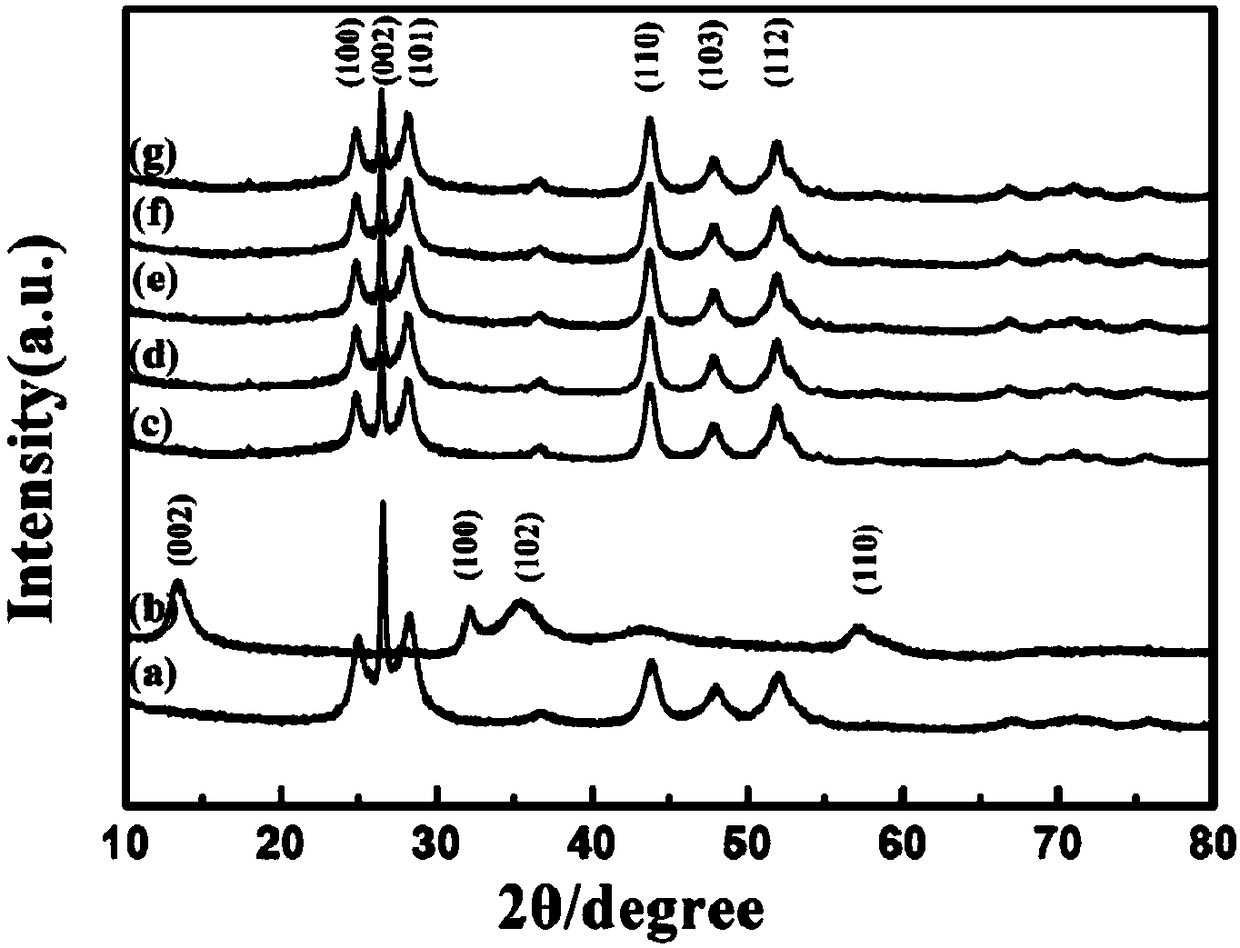

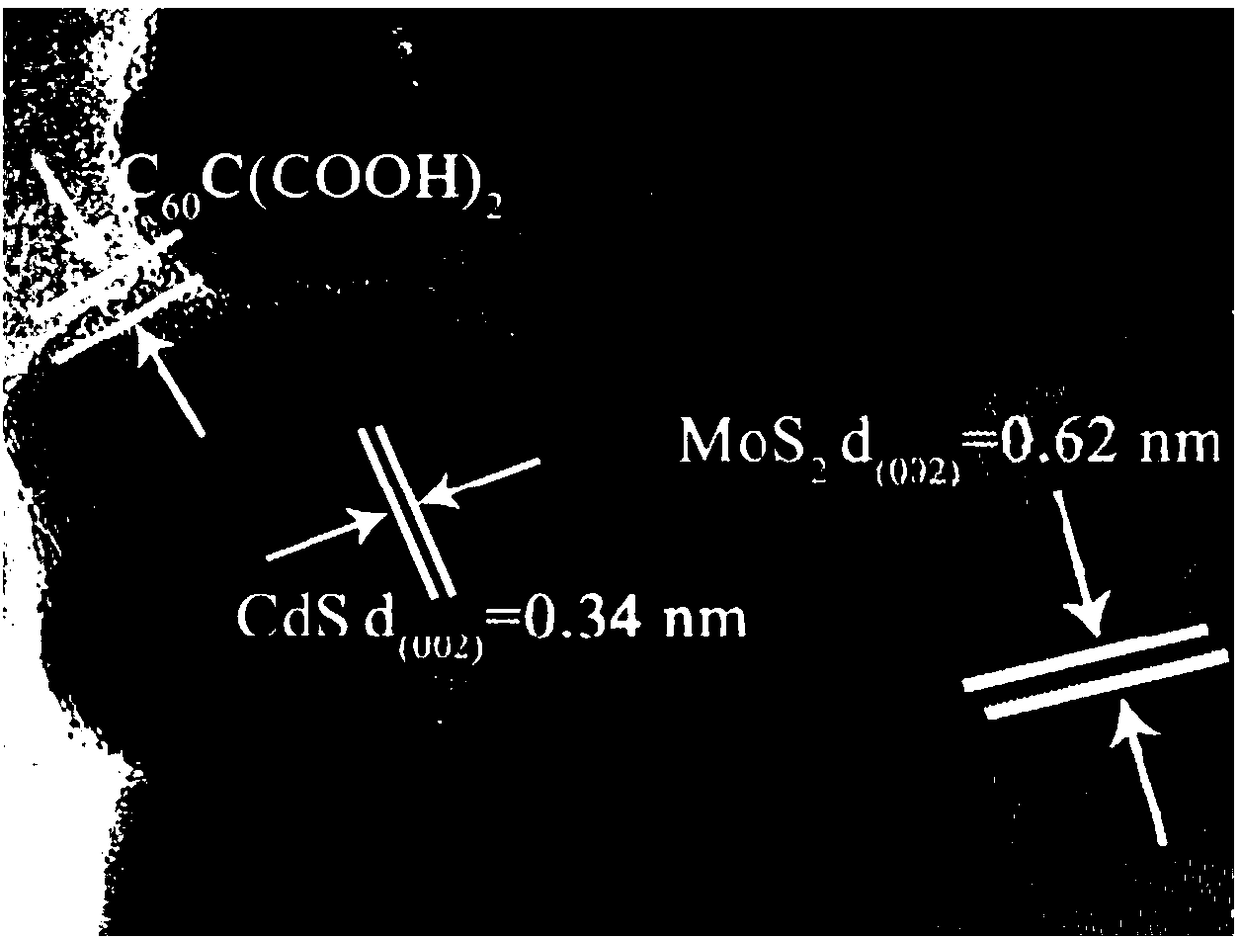

[0027] Weigh 0.266g Cd(Ac) 2 2H 2 O with 0.084g CH 4 N 2 S was dissolved in 60mL ethylenediamine solution, ultrasonically dispersed, and then stirred for 1h. Then transferred to a 100mL polytetrafluoroethylene reactor and reacted at 140°C for 56h. After the reaction, the product was alternately washed with distilled water and ethanol for 3 times, and then vacuum-dried at 50°C for 15h to obtain the target product CdS nanomaterial .

[0028] Then weigh 1.2g Na 2 MoO 4 2H 2 O and 2.2 g of CH 4 N 2 Dissolve S in distilled water, stir for 0.5h, then transfer the solution to a 100mL polytetrafluoroethylene reactor, react at 180°C for 30h, after the reaction is completed and cooled to room temperature, the product is alternately washed 3 times with ethanol and water , and then dried under vacuum at 50°C for 15 hours to obtain the target product MoS 2 .

[0029] Then weigh 10 mg of prepared MoS 2 In a beaker containing 25mL DMF, sonicate at room temperature for 2h to make ...

Embodiment 2

[0033] CdS / MoS 2 The preparation mode of binary composite nanomaterial is the same as embodiment 1.50mg / L C 60 C(COOH) 2 The preparation of the toluene solution is also the same as in Example 1.

[0034] Weigh 50mg of CdS / MoS 2 Binary composite was added to 5mL C 60 C(COOH) 2 in toluene solution, stirred at room temperature for 12h, and after drying, C 60 C(COOH) 2 CdS / MoS with a mass fraction of 0.5% 2 / C 60 C(COOH) 2 Ternary composite materials.

Embodiment 3

[0036] CdS / MoS 2 The preparation mode of binary composite nanomaterial is the same as embodiment 1.50mg / L C 60 C(COOH) 2 The preparation of the toluene solution is also the same as in Example 1.

[0037] Weigh 50mg of CdS / MoS 2 Binary composite was added to 7.5mL C 60 C(COOH) 2 in toluene solution, stirred at room temperature for 13h, and after drying, C 60 C(COOH) 2 CdS / MoS with a mass fraction of 0.75% 2 / C 60 C(COOH) 2 Ternary composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com