Large-thickness electrolytic cutting rectangular section special-shaped tube electrode and machining method thereof

A technology for cutting and processing special-shaped tubes, which is applied in the direction of electric processing equipment, electrochemical processing equipment, processing electrodes, etc., can solve the problems of secondary corrosion, overcutting, and lower processing accuracy, so as to reduce secondary corrosion and improve the flow field , Improve the effect of dimensional accuracy and surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

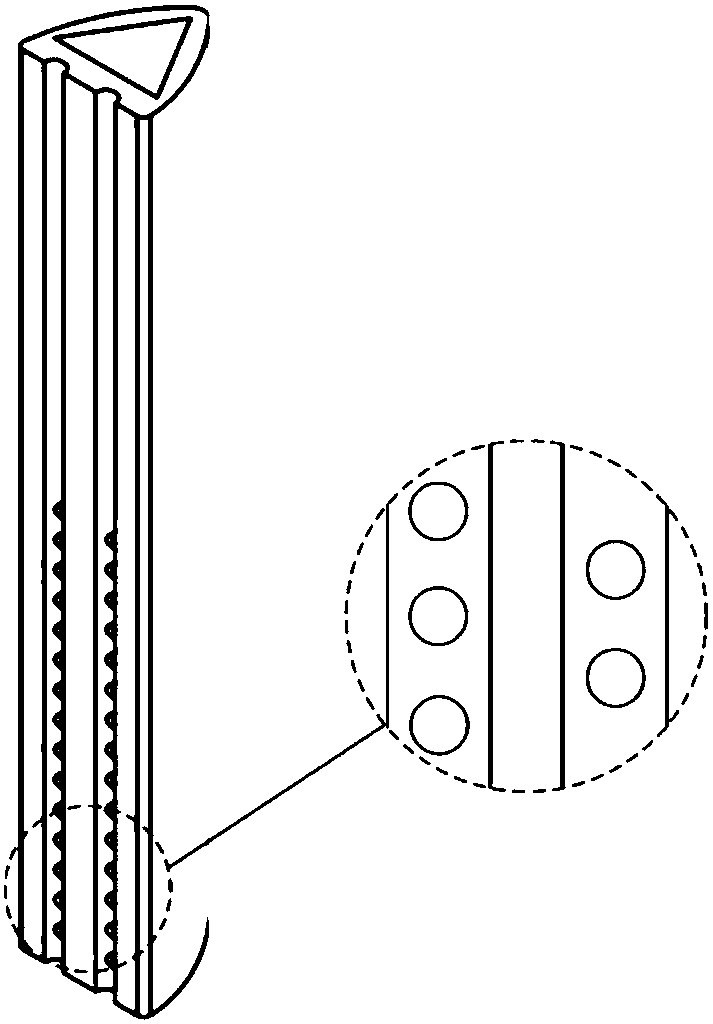

[0026] figure 1 Shown is a schematic diagram of the appearance of a large-thickness electrolytically cut special-shaped tube electrode. Several liquid outlet holes 7 communicate with the central blind hole.

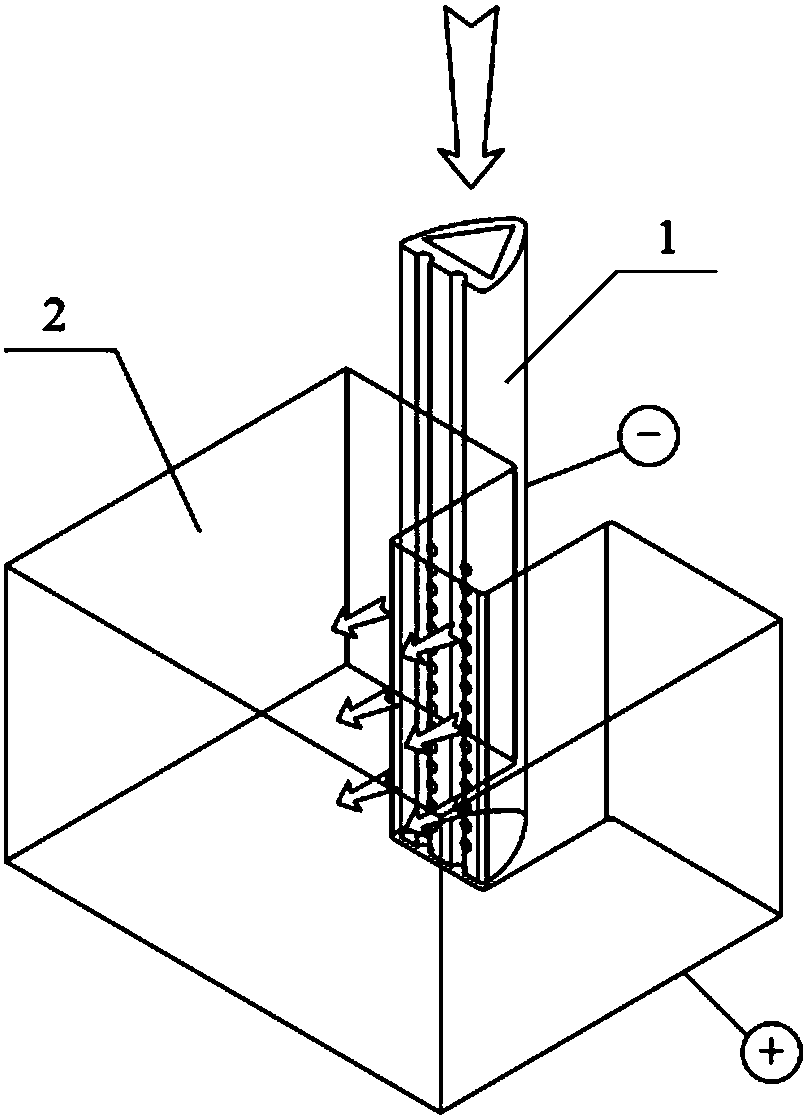

[0027] figure 2 In the schematic diagram of the processing of the special-shaped tube electrode shown in the large-thickness electrolytic cutting, firstly adjust the distance between the liquid outlet hole 7 of the special-shaped tube electrode 1 and the workpiece 2, and ensure that the liquid spray hole of the tube electrode 1 is directly facing the workpiece 2; then, in Set the cutting route in the control system, turn on the power supply 11 and start processing.

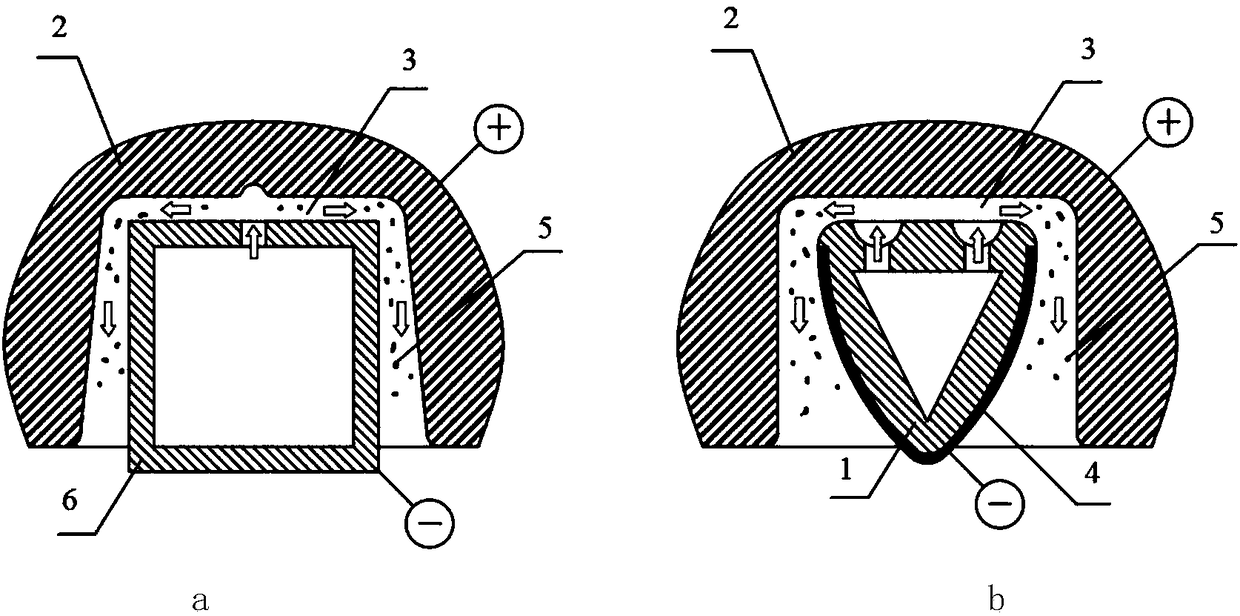

[0028] image 3 In the schematic diagram of the shape profile of the improved processing cross-section of the special-shaped tube electrode shown, the liquid outlet hole of the common rectangular tube electrode 6 is facing the workpiece processing area. The corresponding area produces pits, such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com